Large globs forming on side of nozzle

Hi All.

I'm printing with an i3 MK3S which I purchased last December. It was performing flawlessly up until about a month ago when I gave it a servicing (lubed all smooth rods, bearings etc, checked all nuts and bolts for tightness, and ran the calibration wizard again). After that I started having major problems with large globs of material being deposited on the print at random intervals. Of course the next time the nozzle comes around and hits a solid glob of material things go bad very quickly.

I've done numerous cold pulls, cleaned the outside of the nozzle very carefully, and used the aqua puncture needle to try and clear any blockages that might be in the bore of the nozzle, but the globs still get created.

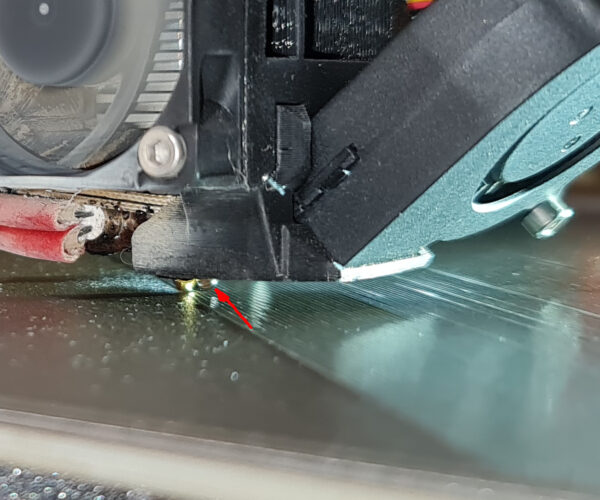

What appears to be happening is that melted filament is building up on the outside of the nozzle. It slowly builds in size until it gets so big it catches on the print and falls off onto the print surface. I have no idea why this is happening and would be grateful for any advice on how to fix the problem. I've attached a couple of pictures showing the glob forming on the nozzle. Apologies for the quality but it is quite difficult to get a good picture.

Finally, please note I'm printing in tranparent Prusament PETG, using default Prusa Slicer settings. Any help or advice would be greatly appreciated.

RE: Large globs forming on side of nozzle

Usually means you've changed nozzles but didn't read the instructions on how to do it correctly.

Unfortunately for many - nozzle changes is a task where following the guidelines is especially important to avoid leaks. If you haven't changed nozzles, then there is a chance you broken the heat break during your last service.

RE: Large globs forming on side of nozzle

Usually means you've changed nozzles but didn't read the instructions on how to do it correctly.

Unfortunately for many - nozzle changes is a task where following the guidelines is especially important to avoid leaks. If you haven't changed nozzles, then there is a chance you broken the heat break during your last service.

Thanks for the reply tim. No, my printer still has the original nozzle and I haven't touched it. I can't think of anything I've done that could have broken the heat break. When servicing I just checked for bolt tightness all around - i.e. I just applied a very small amount of pressure to each nut and if there was no play I left them alone. Do heat breaks have a tendency to break on their own through normal use?

RE: Large globs forming on side of nozzle

I got a similar issue with mine. I think the nozzle don't come very well screwed. Try follow the instruction on how to change it but instead of changing it just clean it before putting it back.

RE: Large globs forming on side of nozzle

Just do the hot tighten part of the process. Heat it to 285 and tighten it up to seal the gap. Clean off the melted plastic and then monitor it for several prints just to make sure no more leaks out.

RE: Large globs forming on side of nozzle

As Neophyl said - retorquing the nozzle might help. This is done at temp, 285c, and is best done with a reliable torque wrench: 3 to 5nM if memory serves -- read the E3D-V6 assembly guide for best results, especially the HOT TIGHTENING section towards the end. A read of the entire document is enlightening, and can save you time and pain when you have to actually service the hot end.

https://e3d-online.dozuki.com/Guide/V6+Assembly/6

ps: keep in mind the hot torque requires the power to be on - and there are exposed wires going to the heater and thermistor. Take special care to NOT touch these parts with your tools - sparks will happen and damage to the electronics is easy to do.

RE: Large globs forming on side of nozzle

This is exactly what I am dealing with, only that I didn't notice until know because it used to happen very little with PLA and only now that I used PETG it got so much worse so that I noticed these huge blobs, even bigger than yours.

I tried to rescrew the nozzle at 285°c, but it was actually really tightly screwed. I noticed the gap between nozzle and heatbloc is very small, almost nonexistent. Rescrewing didn't fix this. Do I have to take the whole thing apart? How do I fix this?

RE: Large globs forming on side of nozzle

@carva

Did that fix the issue for you?

RE: Large globs forming on side of nozzle

@skia

Yes - you have to screw the heat break down a turn or more so the cutout in it is flush with the heater block. Then the nozzle can fit properly.

https://e3d-online.dozuki.com/Guide/V6+Assembly/6

About Step 4 & 5...

RE: Large globs forming on side of nozzle

As a trick - YMMV - you can remove the nozzle, then, holding the heater block, turn the heatsink in place to move the heat break deeper into the block. But you really want to see what you are doing and exposing the hot end it the right way to do the work.

This works to move the heat break down, but doesn't work to raise the heat break - trying for that may unthread the heat break out of the heat sink. And yes, one of Prusa's earlier guides had users do just that - a quarter turn they said - lmao. Made a real mess for me.

RE: Large globs forming on side of nozzle

Thanks for all the replies. I haven't been able to try tightening the nozzle yet as I don't have a socket that will fit it, and I don't want to try and do it with just pliers. I hope to get a set of small sockets this week and will try it as soon as I can.

Having said that, I'm pretty sure that the material isn't leaking from the nozzle body and the hotend or heatbreak. The reason for saying that is as follows:

I've just finished a large (covers almost the entire build area and took 34 hours to complete) print. I was printing in Prusament clear PETG using Prusa Slicer default 0.2mm quality settings. I was only able to complete the print by observing the first seven or so layers almost constantly, and pausing the print to remove the globs that formed on the side of the nozzle before they got large enough to fall off onto the print.

The worst globs appeared on the first layer. I had to pause the print about seven times to remove globs with a brass brush. With the second layer things improved a bit and I only had to pause the print three times. The third and fourth layers I only had to pause the print once on each layer. The fifth layer was the first layer with infill (gyroid at 15%). From then on the globbing on the side of the nozzle disappeared entirely.

From what I was able to observe the globs were forming by excess plastic being brushed up onto the side of the nozzle where it slowly accumulated to form a glob of melted material. Also the side of the nozzle on which the globs formed changed to the opposite side each time the print direction changed. I didn't see any plastic dripping down from where the nozzle attaches to the hotend or heatbreak. So my current theory is that I have the first layer Z calibration set too low and the nozzle is effectively scraping material off the print onto the side of the nozzle - a bit like a snow plow. (Though I'm not sure why globs would continue to form to a lesser extent on layers 2, 3 and 4).

I will be recalibrating first layer and running an extensive test to see if my theroy is correct, but it will be a few days before I can get around to that due to other commitments. In the meantime I'd be interested to hear what you think about my theory.

Thanks again to all for your input.

RE: Large globs forming on side of nozzle

@brian-swan

About the only thing that will cause a blob to form in the direction of travel is over-extrusion (on an otherwise normally working printer).

Hope you get it figured out.

RE: Large globs forming on side of nozzle

I have read that an over low live z might encourage petg accumulation on the nozzle. Cant vouch for this. Likewise PETG can lay down a first layer a bit higher than PLA.

i3 Mk3 [aug 2018] upgrade>>> i3MK3/S+[Dec 2023]

RE: Large globs forming on side of nozzle

@john-6

No doubt about it and PETG can be more resistant to being over squished.

--------------------

Chuck H

3D Printer Review Blog