Large blobs - what to do?

Hi,

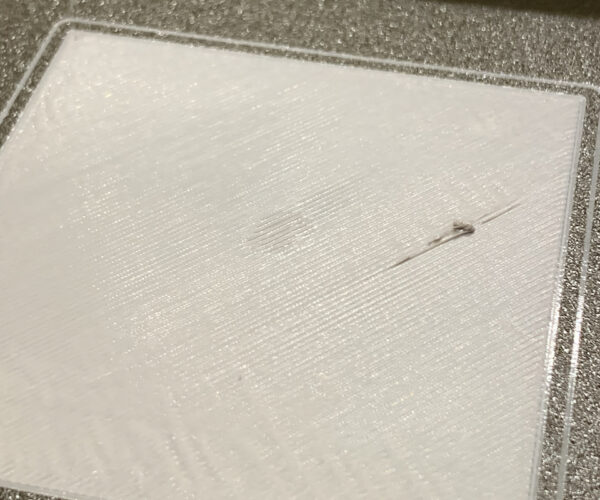

after now about 200-300hrs of printing without any issues (got the Mk3s+ 4 weeks ago), I now have some issues with blobs on the first two layers.

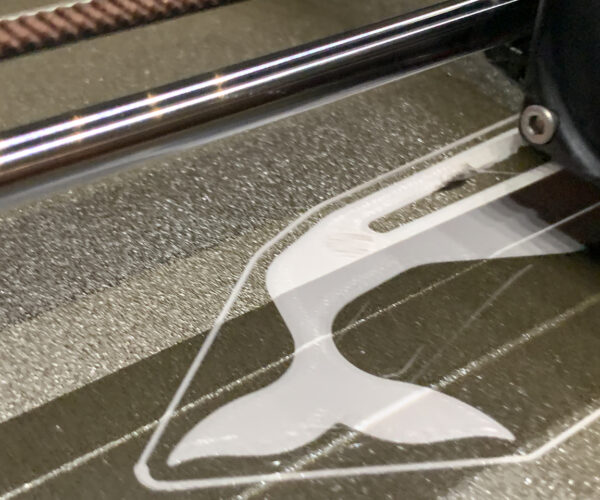

One print before I printed a huge STL, 34hrs with PLA - without any issues. Now a small PETG print and I get several large blobs on the first or following layers, that end up in a crash.

I use Prusamanet PETG and have the issue with different spools. I can extrude with issues. My first idea was, that there might be a gab between nozzle and the Bowden inside. But cannot see any material coming out of the hotend.

Weird is, that I got the blobs while printing the whale very close to the same position of printing. An area where the it prints very short lines (= high pressure variation?).

What is your recommendation for the next step?

I appreciate your help!

RE: Large blobs - what to do?

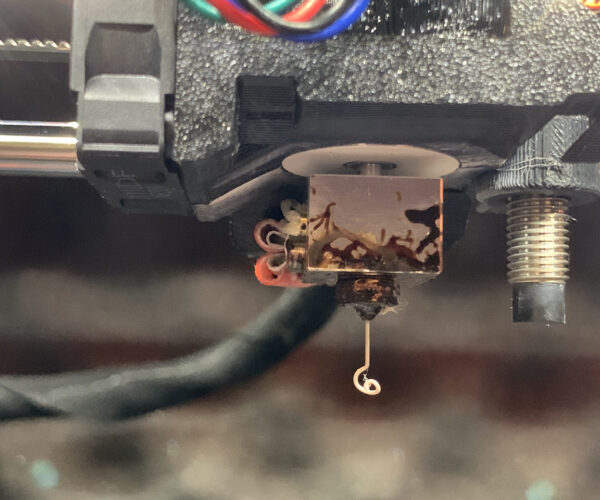

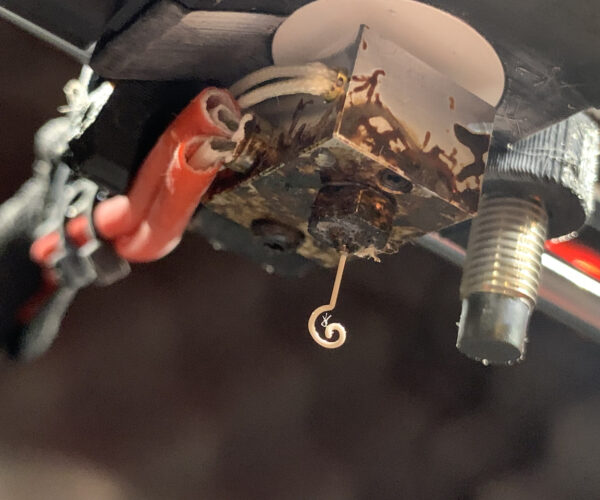

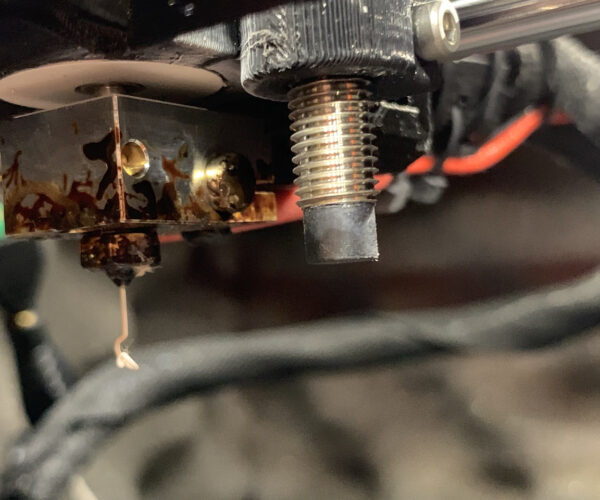

Well, just after uploading the images I saw, that there might be some material between hotend and nozzle where should been a small gap.

RE: Large blobs - what to do?

You nailed it.

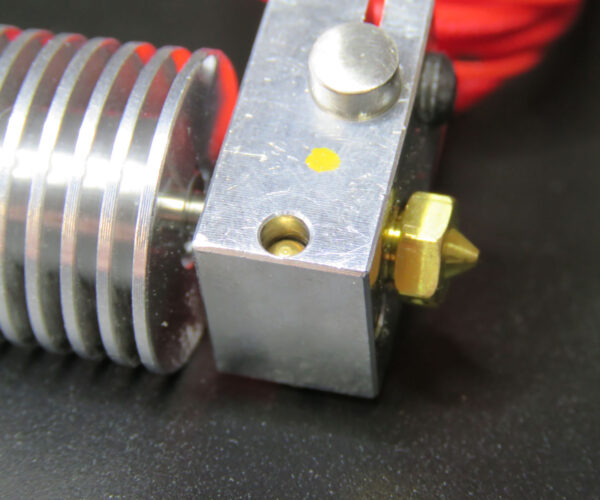

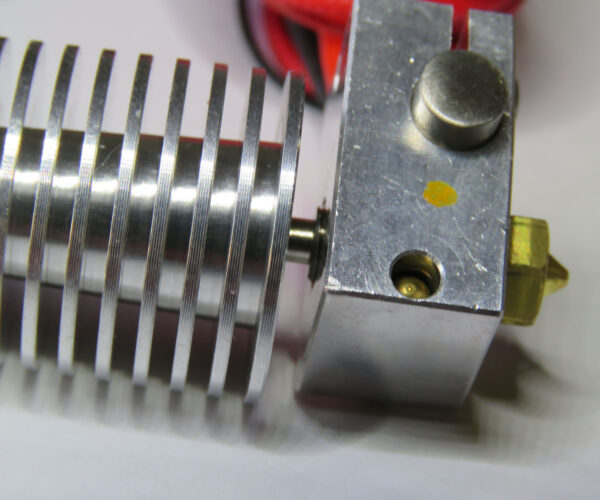

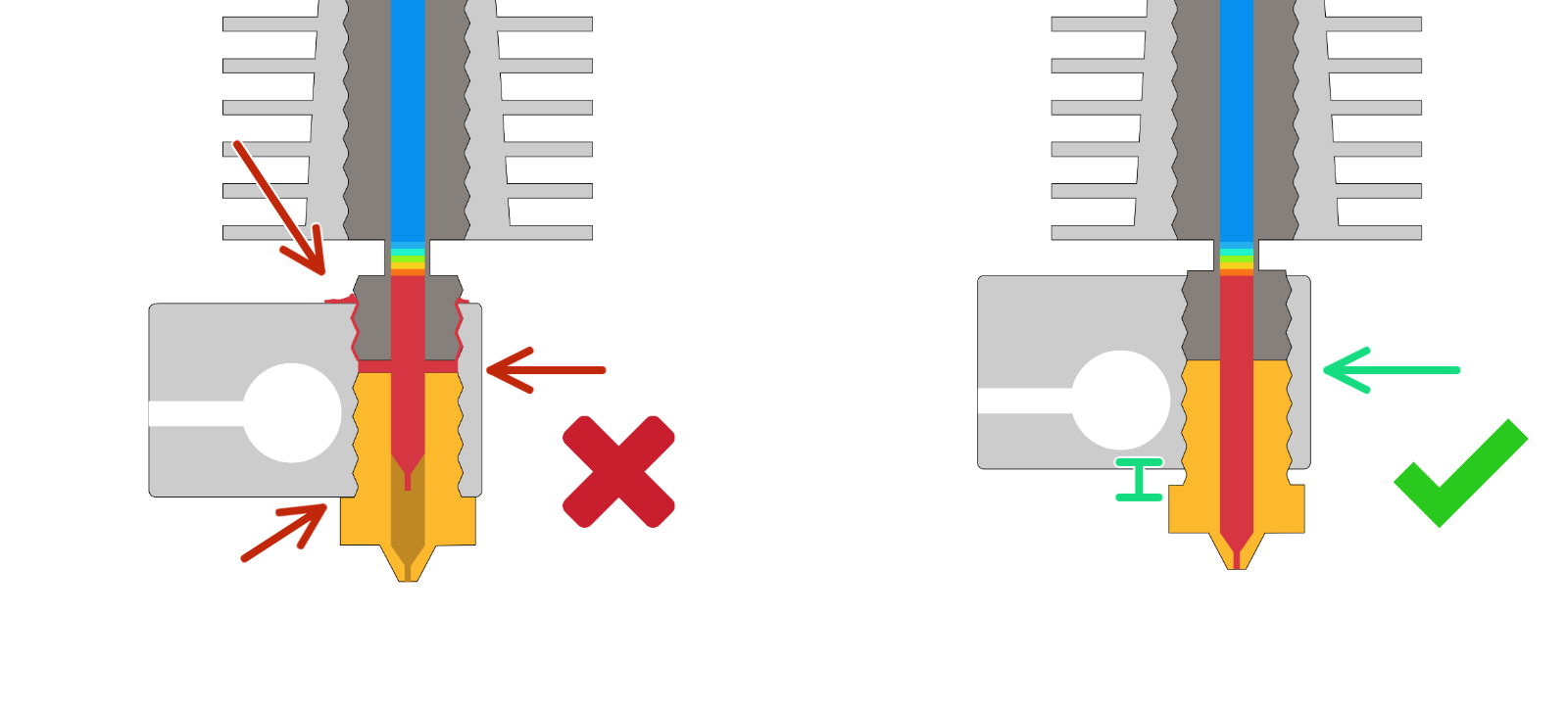

If correctly assembled there's a gap between the nozzle and the bottom of the heater block.

Carefully follow the instructions in Prusa's Knowledgebase:

[Mk3S]( https://help.prusa3d.com/en/article/changing-or-replacing-the-nozzle_2069)

[Mini]( https://help.prusa3d.com/en/article/changing-replacing-the-nozzle-mini_134235)

Here's a schematic of an E3D v6 hotend:

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: Large blobs - what to do?

And much better than the Prusa guides which I found misleads users in places, is the E3D-V6 guides.

RE: Large blobs - what to do?

@smutje

Actually, there should not be a small gap. There should be no gap.

--------------------

Chuck H

3D Printer Review Blog

RE: Large blobs - what to do?

@cwbullet

Wrong. There is always a gap between the nozzle HEX and heater block.

RE: Large blobs - what to do?

@tim-2

I think you are wrong. There should never be a gap between the nozzle and the heartbreak.

--------------------

Chuck H

3D Printer Review Blog

RE: Large blobs - what to do?

@tim-2

I think you are wrong. There should never be a gap between the nozzle and the heartbreak.

I misunderstood above - I read heatbreak and not heat block.

--------------------

Chuck H

3D Printer Review Blog

RE: Large blobs - what to do?

@tim-2

Reading is fundamental for both of us. Read the last 3 posts.

--------------------

Chuck H

3D Printer Review Blog

RE: Large blobs - what to do?

That's the problem with always adding commentary to other peoples posts and not adding value to the discussion. Like this post of mine is NOT doing - there's no value to the OP in complaining. So I'll go away now and wait for the OP to reply that they have actually implemented the suggestions given.

RE: Large blobs - what to do?

@smutje

Tim is 100% correct! There is always a gap between the nozzle HEX and heater block. no if's ands or butts.

Now that that is settled, your images do appear to show that your nozzle hex might be a bit to close to your heater block as Tim was trying to say before he was so rudely interrupted. you may want to look into this.

Regards

Swiss_Cheese

The Filament Whisperer

RE: Large blobs - what to do?

@cwbullet

I like you Charles, but you do seem to just pop into posts for no apparent reason and say things that offer no real worth to the post, one might think your just trying to have the last word or even just fill the comments with your handle for no parent reason, or maybe just to elevate your tag by going for famed member, even though all the tags really mean is that someone posts a lot, and have no bearing what so ever on a persons printing experience, or the worth of that persons advice. I'm going to say it is bit obnoxious, and unnecessary. I'm going to suggest that you rethink this way of being, it's one thing to pop in with a joke or a good bit of advice, but just jumping in at the end of every post and saying 3 words of no real meaning is not kewl.

The Filament Whisperer

RE: Large blobs - what to do?

Wow, a lot of posts while I was sleeping - thanks a lot for your schematic @fuchsr !

today I dissambled the hot end and checked if there are any clogs, but not even saw any material in the thread. If there was a gap between the nozzle and the heatbreak and that was the reason for the blobs, there must have been any material on the thread?!

I still don't know what's causes the blobs, but, in the end I broke the cable of the heater cartridge. Now I need a new one and will additionally swap the heater block, heartbreak and nozzle. 🙁

RE: Large blobs - what to do?

Your hot end was leaking due to assembly error. If the HEX of the nozzle is touching the heater block, which your photos show, it isn't touching the heat break properly. The nozzle and heat break are torqued together, not the nozzle and heater block. The block is only used for leverage. An abstract concept, I know, but just read the instructions and follow them before coming back and saying it's leaking again and you still have blobs.

RE: Large blobs - what to do?

@tim-2

I understand the concept now and to underline your comment, it seems that the heater blocker was a little bit loose.

RE: Large blobs - what to do?

[...] I like you Charles, but ...

Hey now, Chuck put up a mea mulpa. Let's face it, the short editing window makes us all look like idiots. The inability to go back and correct minor problems even 30 minutes after a post lead to a lot of extra corrections and confusion. Between that and autocorrect insisting that "heatbreak" means "heartbreak".

Rather than say "there should be a gap", I prefer to say "if you've assembled it correctly, there is NO WAY there will NOT be a gap".

What the hell is the proper name for the "hex" part of the nozzle anyhow. Hex is all I can think of, but I'm sure machinists have a smarter-sounding word for that part. Same question for the "collar" around the nozzle opening. Is there a better name for it?

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Large blobs - what to do?

The straight section above the 'hex' part would probably be referred to as a 'shank'.

Some of the earliest nozzles were turned down from bolts and bored through and the section between the head and threads is called shank so it pretty much describes the same area on a nozzle.

RE: Large blobs - what to do?

Ah, sorry. I meant the hex part itself. Is there a better name for it?

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Large blobs - what to do?

I believe that with the technical reason in mind, it is much better to understand, why there is small gap between hexagon-part of the nozzle and the heater block: double fit! (I hope this is the correct English wording for the German "Doppelpassung")

When you screw the nozzle completely in, you will not be sure if you just screwed against the heater block or if you reached the end of the heatbreaker. As long as you have a >0mm gap between hexagon and block and you feel a torque while turning the nozzle, you know, that you just sealed nozzle and heatbreaker.

Please name other reasons, but I think this is the only one.

The Prusa instruction advises to first turn the block small turn to the side (to the PINDA) and the last steps are to screw the nozzle up to 3Nm torque and then turn the block back to the original position. This turn in the end will screw the heatbreak more in the block, eg. more pressure. So I assume the torque of the assembled part is about 6-10 Nm.

Finally I have a questions to step 14 of the Extruder Assembly. How strong do I have to tighten the screws o the body to make sure, that the heat sink does not rotate anymore. While I changed the nozzle and turned the heater block, I recognised that I actually rotate the whole metal extruder. This can be really an issue and is just okay, as long as we see a gap between the hexagon and the block.

RE: Large blobs - what to do?

@smutje

The position of the heat break in the heater block is important. The neck is there as an insulator. You to not want the neck inside the heater block where it conducts too much heat to the heat sink or is hot enough to melt plastic. Also, you want the entire heat break hot-end inside the heater block so it is hot enough to melt plastic.

So the position of the heat break is important. You can't get the proper position if the nozzle is too deep or too shallow in the heater block.

The heater block threads and neck on the heat break should be flush with the heater block. Though a bit high -- 1/4 turn? --seems to be a common assembly finish for E3D.