Issues with heat bed adhesion and different steel sheets

Hi there,

I do have some mayor issues for about a week now and don't know how to settle them.

I'm not able to print anymore and very frustated right now. First of all, this is not my first printer and I'm not a newbee to the materia 😉 But maybe I'm overlooking something, especially in my frustration.

Short story:

Everything worked like a charm for months. Using both PEI and powdered sheet. Using PLA and PETG. Recently I've been printing PETG mostly. Then, the adhesion to the bed got worse and worse until I wasn't able to print anything with PETG. I tried the delivered glue stick with the powdered sheet and it did help for about 2 prints, and then not anymore. Even the total sheet covered in glue did not help.

Ok, then back to PLA and the PEI sheet. Same issue. Did not stick... frustration took place.

I checked the web, found a tipp, to temper the PINDA sonde before doing the meshbed by M860 gecode. Did this, does work, but does not help at all.. Just takes longer, as the PINDA will be tempered to 35 °C before leveling.

Then I checked again and found the NylokMod. Did this. Total deviation of the bed level is down to 0.05 mm. Pretty good I think and more than sufficient (from 0.278 mm before the mod).

Still, the PLA won't stick very well.

Ok, maybe the nozzle is worn out after these 4 months. New nozzle installed, tested, live Z adjusted, everything fine. New print, does not stick again... There is like an area, the filament wont stick on the bed.

Tried to clean the PEI sheet with glass cleaner, soap w hot water and Isopropanole as well. Super clean and sticky over some area, and then the print does not stick.

Now some pictures, to show you what I mean:

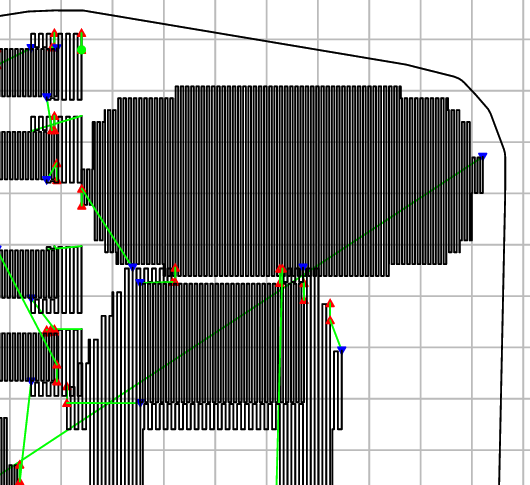

This is the area I will show you in the pictures. I'm so desperate, that I tried to print everything on a raft layer to help with adhesion. So the top right is the raft area, below is an area of support and raft (suqare in the middle of it).

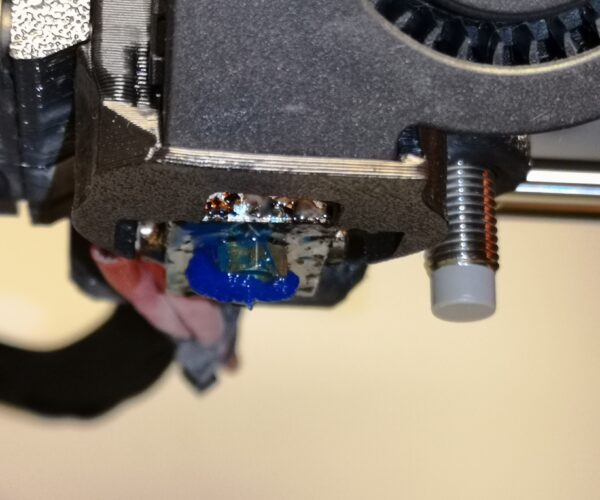

It prints the raft, somewhat ok. It already starts to rip off at the lower end (only?!). Then start the support and afterwards wants to print the second raft area. But this does not stick at all and just clogs around the nozzle.

Here are the pics:

This happens over several print, evertime. If the lines are too thin, the layers does not stick.

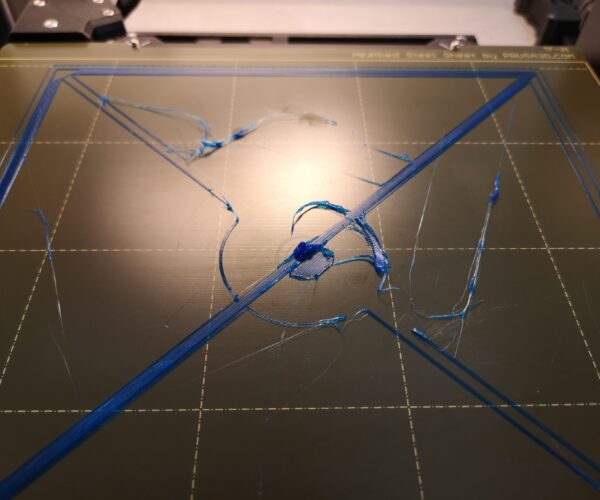

Here is a first layer test as well:

First pic is during print, second after I stopped it a few minutes later. It should look like this:

You see, the center circle perimeters did not stuck. Then it tried to print the infill, somewhat worked, but then the adhesion is gone...

I really hope someone can help me here...

Thanks in advance.

Cheers

Best Answer by JustMe3D:

My 2 cents, for what it´s worth. Isopropanol doesn´t clean the sheets. Dish detergent and hot water do not either. For me the solution is a combination of non-regreasing dish detergent, hot water, a hard kitchen sponge, intense rubbing of the bed and then vigorously scrubbing the bed with kitchen paper towels. For some time, when the adhesion problems occured first after a couple of dozen prints or so, I occasionally even used a small cordless Bosch delta-sander, placing the bed between two sheets of paper towel and then giving the bed a good rubbing with the paper towel for some 10 seconds. Over time I have come to cleaning the bed after every single print with hot water, detergent and a paper towel instead of every 5th or so print. Since then, any adhesion issues are a distant memory only. My OEM PEI sheet which was delivered with the MK3S has 120 days of printing; thereof PETG for the first I guess 40 print days and ASA for the remaining time and I have only now coughed up the money for the new satin sheet or whatever it´s called; I still have that PEI sheet and it certainly has its marks, dents etc but it is still nicely usable.

My PETG was a local German filament seller´s (3DJake) own brand and my ASA is Spectrum ASA 275, which is my all-purpose weapon of choice and of which I have printed certainly more than 10kg on that original PEI sheet. I don´t dry my filament (ever) and store it in an airtight ziploc bag with a small bag of silicagel to suck up any moisture. If I use "difficult" filament I turn to Kores glue sticks as was at that time part of the delivery with the printer; I have tested other well-known brands and found Kores to be working perfectly for me, particularly as I have never to print with a bed temperature north of 75 degrees celsius; my ASA prints run on 60 degrees bed temp. Another option I sometimes turn to is 3DLac, which smells like hairspray to me and seems to be working particularly great on the satin sheet, particularly when I print parts with a very small footprint. And yes, I clean the sheet after every use with hot water, detergent and paper towels.

Cheers

Chris

RE: Issues with heat bed adhesion and different steel sheets

nicoseeleib, I had the same issue. PETG was a big problem with the first layer. PLA is better but still not perfect. I found certain areas on the print bed were worse so I try to position parts in better areas. Still not perfect. I ended up lowering the first layer speed to 10 mm/sec. It seems to help but hate to add time to a print. I'm still working through this but I have to think that the flexible metal sheet is the issue. Only way to know if that helps is get a new sheet. I'm still working around it by slowing the first layer and using glue stick but I do plan on ordering a new build sheet. I have another printer that I printed on a mirror panel. Print adhesion was always predictable. If the height calibration was off I had problems. As long as first layer calibration was good, it would stick as expected. There are other possibilities, such as my aluminum base plate may have some slight warps in spots. I also know with magnets, they don't like heat. It causes them to loose strength. This may have an effect on Z level calibration. I'm not sure if the Z level calibration depends on magnet strength. I do know that over time magnets loose their strength and especially in a hot environment. Anyway my suggestion is to try and slow the first layer to a crawl. If anything it lets you watch what's going on as the first layer is being extruded.

RE: Issues with heat bed adhesion and different steel sheets

Hi there,

I do have some mayor issues for about a week now and don't know how to settle them.

I'm not able to print anymore and very frustated right now. First of all, this is not my first printer and I'm not a newbee to the materia 😉 But maybe I'm overlooking something, especially in my frustration.

Short story:

Everything worked like a charm for months. Using both PEI and powdered sheet. Using PLA and PETG. Recently I've been printing PETG mostly. Then, the adhesion to the bed got worse and worse until I wasn't able to print anything with PETG. I tried the delivered glue stick with the powdered sheet and it did help for about 2 prints, and then not anymore. Even the total sheet covered in glue did not help.Ok, then back to PLA and the PEI sheet. Same issue. Did not stick... frustration took place.

I checked the web, found a tipp, to temper the PINDA sonde before doing the meshbed by M860 gecode. Did this, does work, but does not help at all.. Just takes longer, as the PINDA will be tempered to 35 °C before leveling.

Then I checked again and found the NylokMod. Did this. Total deviation of the bed level is down to 0.05 mm. Pretty good I think and more than sufficient (from 0.278 mm before the mod).

Still, the PLA won't stick very well.

Ok, maybe the nozzle is worn out after these 4 months. New nozzle installed, tested, live Z adjusted, everything fine. New print, does not stick again... There is like an area, the filament wont stick on the bed.

Tried to clean the PEI sheet with glass cleaner, soap w hot water and Isopropanole as well. Super clean and sticky over some area, and then the print does not stick.

Now some pictures, to show you what I mean:

This is the area I will show you in the pictures. I'm so desperate, that I tried to print everything on a raft layer to help with adhesion. So the top right is the raft area, below is an area of support and raft (suqare in the middle of it).

It prints the raft, somewhat ok. It already starts to rip off at the lower end (only?!). Then start the support and afterwards wants to print the second raft area. But this does not stick at all and just clogs around the nozzle.

Here are the pics:

This happens over several print, evertime. If the lines are too thin, the layers does not stick.

Here is a first layer test as well:

First pic is during print, second after I stopped it a few minutes later. It should look like this:

You see, the center circle perimeters did not stuck. Then it tried to print the infill, somewhat worked, but then the adhesion is gone...

I really hope someone can help me here...

Thanks in advance.

Cheers

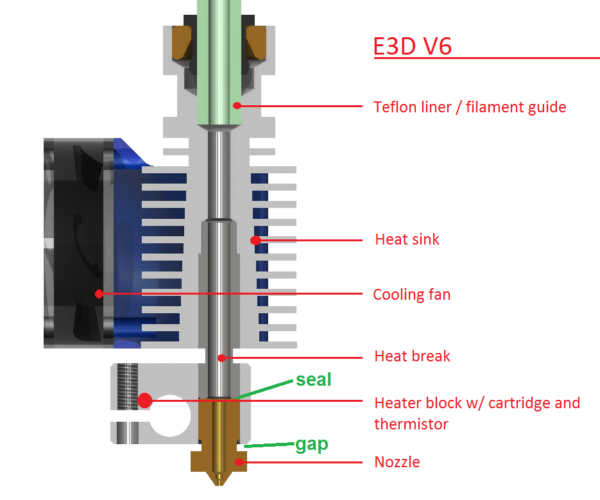

Did you try another Filament? Maybe your nozzle leaks? I would disassemble the hotend, clean all components and and make sure that the nozzle seals against the heatbreak. Maybe replace the nozzle. Bed must be superclean and good leveled.

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.

RE: Issues with heat bed adhesion and different steel sheets

Clean bed with dish soap 2 times, with hot water. Nothing else is needed.

Then first layer should be 100%.

This should be enough to get it working.

Extra, normally not needed:(possible bad filament, water in filament).

First layer slow down to 10 mm

First layer, make extruder hotter 5 or 10 C.

Make bed hotter.

RE:

Hi there,

I do have some mayor issues for about a week now and don't know how to settle them.

I'm not able to print anymore and very frustated right now. First of all, this is not my first printer and I'm not a newbee to the materia 😉 But maybe I'm overlooking something, especially in my frustration.

Short story:

Everything worked like a charm for months. Using both PEI and powdered sheet. Using PLA and PETG. Recently I've been printing PETG mostly. Then, the adhesion to the bed got worse and worse until I wasn't able to print anything with PETG. I tried the delivered glue stick with the powdered sheet and it did help for about 2 prints, and then not anymore. Even the total sheet covered in glue did not help.Ok, then back to PLA and the PEI sheet. Same issue. Did not stick... frustration took place.\

I have had very nearly the same experience. I print PETG only. After adhesion problems with the steel sheet, I installed a powdered sheet and printed happily for two or three prints. Then, adhesion problems...the bead didn't stick to the sheet and clogged the print nozzle. Did First Layer Calibration veery carefully and at last got near perfect test patterns to stick, but my prints still would not.

Thinking of getting a new powdered sheet but if possible I'd like to save the money and time.

So I've come begging help. Anyone have a clue for the clueless? Many thanks.

RE:

My 2 cents, for what it´s worth. Isopropanol doesn´t clean the sheets. Dish detergent and hot water do not either. For me the solution is a combination of non-regreasing dish detergent, hot water, a hard kitchen sponge, intense rubbing of the bed and then vigorously scrubbing the bed with kitchen paper towels. For some time, when the adhesion problems occured first after a couple of dozen prints or so, I occasionally even used a small cordless Bosch delta-sander, placing the bed between two sheets of paper towel and then giving the bed a good rubbing with the paper towel for some 10 seconds. Over time I have come to cleaning the bed after every single print with hot water, detergent and a paper towel instead of every 5th or so print. Since then, any adhesion issues are a distant memory only. My OEM PEI sheet which was delivered with the MK3S has 120 days of printing; thereof PETG for the first I guess 40 print days and ASA for the remaining time and I have only now coughed up the money for the new satin sheet or whatever it´s called; I still have that PEI sheet and it certainly has its marks, dents etc but it is still nicely usable.

My PETG was a local German filament seller´s (3DJake) own brand and my ASA is Spectrum ASA 275, which is my all-purpose weapon of choice and of which I have printed certainly more than 10kg on that original PEI sheet. I don´t dry my filament (ever) and store it in an airtight ziploc bag with a small bag of silicagel to suck up any moisture. If I use "difficult" filament I turn to Kores glue sticks as was at that time part of the delivery with the printer; I have tested other well-known brands and found Kores to be working perfectly for me, particularly as I have never to print with a bed temperature north of 75 degrees celsius; my ASA prints run on 60 degrees bed temp. Another option I sometimes turn to is 3DLac, which smells like hairspray to me and seems to be working particularly great on the satin sheet, particularly when I print parts with a very small footprint. And yes, I clean the sheet after every use with hot water, detergent and paper towels.

Cheers

Chris

I try to give answers to the best of my ability, but I am not a 3D printing pro by any means, and anything you do you do at your own risk. BTW: I have no food for…

RE: Issues with heat bed adhesion and different steel sheets

I know the most heated discussions I've seen (and was in) have to do with the "Clean your plate and clean it my way!" admonition.

I don't believe that how you clean it, and what you use to clean it, is important as the fact that you do clean it and get it very free of oil, fingerprints, dirt, etc.

If anyone cares, I seldom use anything other than isopropyl. I have very few failed prints, close to none for adhesion issues. I must be doing something right, huh?

RE: Issues with heat bed adhesion and different steel sheets

May I ask for the dish soap you use?

Also auch gerne die deutsche Marke 😉

My 2 cents, for what it´s worth. Isopropanol doesn´t clean the sheets. Dish detergent and hot water do not either. For me the solution is a combination of non-regreasing dish detergent, hot water, a hard kitchen sponge, intense rubbing of the bed and then vigorously scrubbing the bed with kitchen paper towels. For some time, when the adhesion problems occured first after a couple of dozen prints or so, I occasionally even used a small cordless Bosch delta-sander, placing the bed between two sheets of paper towel and then giving the bed a good rubbing with the paper towel for some 10 seconds. Over time I have come to cleaning the bed after every single print with hot water, detergent and a paper towel instead of every 5th or so print. Since then, any adhesion issues are a distant memory only. My OEM PEI sheet which was delivered with the MK3S has 120 days of printing; thereof PETG for the first I guess 40 print days and ASA for the remaining time and I have only now coughed up the money for the new satin sheet or whatever it´s called; I still have that PEI sheet and it certainly has its marks, dents etc but it is still nicely usable.

My PETG was a local German filament seller´s (3DJake) own brand and my ASA is Spectrum ASA 275, which is my all-purpose weapon of choice and of which I have printed certainly more than 10kg on that original PEI sheet. I don´t dry my filament (ever) and store it in an airtight ziploc bag with a small bag of silicagel to suck up any moisture. If I use "difficult" filament I turn to Kores glue sticks as was at that time part of the delivery with the printer; I have tested other well-known brands and found Kores to be working perfectly for me, particularly as I have never to print with a bed temperature north of 75 degrees celsius; my ASA prints run on 60 degrees bed temp. Another option I sometimes turn to is 3DLac, which smells like hairspray to me and seems to be working particularly great on the satin sheet, particularly when I print parts with a very small footprint. And yes, I clean the sheet after every use with hot water, detergent and paper towels.

Cheers

Chris

May I ask for the dish soap you use?

We usually suggest Dawn & Fairy as they are well known brands but honestly, what you really want is pure detergent with no additives. Many supermarket own-brands are suitable, just check on the bottle.

Cheerio,

RE: Issues with heat bed adhesion and different steel sheets

I use Pril, Spüli or Frosch, preferably the concentrated version, but only those versions without any additional skin-caring substances like AloeVera and the like because these will apply a grease film to the PEI sheet.

Regards

Chris

I try to give answers to the best of my ability, but I am not a 3D printing pro by any means, and anything you do you do at your own risk. BTW: I have no food for…

RE: Issues with heat bed adhesion and different steel sheets

...

If anyone cares, I seldom use anything other than isopropyl. I have very few failed prints, close to none for adhesion issues. I must be doing something right, huh?

Same here.

I noticed, that many, as soon they start to get adhesion troubles (because of whatever other reasons), start to smudge all kind of stuff on print sheet -which, over the time, only makes things worse.

What do we mean when we say print sheet must be "clean"? Simple: no dust (or filament remains) on it, and absolutely no fingerprints! To remove dust and small filament particles, IPA is enough. For full cleaning, a little of cheap classic soap should be used and finally rinsed with good amount of clean water.

Most other cleaner (dish washer, liquid soap, whatever) have "skin friendly" ingredients (and scents), which are sometimes hard to get rid off. Just try to wash hands with dish washer (or liquid soap) and compare with normal soap -difference is obvious.

[Mini+] [MK3S+BEAR]

RE: Issues with heat bed adhesion and different steel sheets

Looks like you have not even read the postings referring to non-regreasing detergent.

I try to give answers to the best of my ability, but I am not a 3D printing pro by any means, and anything you do you do at your own risk. BTW: I have no food for…

RE: Issues with heat bed adhesion and different steel sheets

In expert settings lower first layer speed to 15mm/sec. They always default to 20mm/sec. That causes a lot of trouble. Second, if still having some trouble use purple Elmers school glue stick. It has to be the purple. It holds up best to the heated bed. If you have a coat of glue and use lower speed, cleaning the sheet doesn't even come into play. PLA usually works fine on lower first layer speed without glue. I just add glue when 1st layer is trouble. Especially if using supports. They're tough to get a good 1st layer. Of course that's assuming you have good bed calibration. Sounds like you do. Can't hurt! Give it a try. It worked for me when nothing else would.

RE: Issues with heat bed adhesion and different steel sheets

I know the most heated discussions I've seen (and was in) have to do with the "Clean your plate and clean it my way!" admonition.

I don't believe that how you clean it, and what you use to clean it, is important as the fact that you do clean it and get it very free of oil, fingerprints, dirt, etc.

I found the following about powder coated sheets at

https://blog.prusaprinters.org/how-to-print-on-a-powder-coated-sheet_30178/

I have cleaned my powder coated sheet with dish soap - but only after the adhesion problem cropped up. I'm wondering if I need to buy a new sheet.

Print surface preparation

Do not apply any adhesive or separation layers on powder-coated sheets. All you need for a successful print is just a little bit of isopropyl alcohol (IPA) 90%+ as a degreaser (do not use Acetone! – see the explanation below). Apply IPA on a paper towel and clean the cold surface with it. If your print surface is hot, IPA will evaporate quickly and you won’t be able to clean the surface perfectly.

Calibration of the first layer

Do not forget that powder-coated sheets have a different thickness than smooth PEI sheets, therefore it is required to do the First layer calibration. Please note, that the improper adjustment of the first layer height can lead to damage of the sheet’s surface. This type of damage is not covered by your warranty!

While it’s true that it’s necessary to lower the nozzle more (compared to the smooth PEI sheet), it is important not to overdo it. The extruded filament should completely fill all gaps of the print surface while remaining smooth and flat on the top during the print of the first layer. If you set the nozzle too high, your object will not stick to the surface. If you set the nozzle too low, the extruded filament will either stick to the nozzle and peel off from the surface or (in the worst case scenario) you might damage your sheet.

My prints still don’t stick to the surface – what should I do?

If your print surface is perfectly clean, degreased with isopropyl alcohol and the first layer height is set up properly, your prints should (with only a few exceptions) stick to the plate very well. Small parts (especially printed from PLA) can detach due to a small contact area. In these cases, it’s better to use a smooth sheet that will ensure perfect adhesion. If you want to print small parts on a powder-coated sheet anyway, it is recommended to use a brim. The Brim function can be found in PrusaSlicer in the right panel, nex to infill density or under the tab Print settings – Skirt and Brim – Brim. Set the brim to at least 3 mm for better adhesion.

Do not use solvents other than IPA under any circumstances!

Acetone, in particular, must not be used on the powder-coated sheet! Using acetone makes the surface (Ultem) crack, and eventually, it peels off. Also, the powder-coated sheet is not waterproof. When exposed to high humidity, it corrodes and loses its properties. Therefore, do not clean the sheet with water. It is possible to do that only if you have truly tried everything mentioned and your objects still don’t stick to the surface. It could mean that you have sugar-based compounds on your sheet that can’t be dissolved with IPA.

Do:

Degrease the sheet with isopropyl alcohol (IPA) 90%+

Print without any adhesive or separation layers

Print supported materials (PETG, PLA, PC, CPE, PVA/BVOH, HIPS, Flex, nGen, Nylon)

Remove prints after the cooldown

Bend the sheet to remove printed objects

Don’t:

Use acetone and other agents

Print with adhesive or separation layers

Wash the sheet with water

Remove printed objects before cooldown

Use any instruments (spatula) to remove the printed object

Powder-coated sheets are a very good choice for printing all standard types of materials, without using additional adhesive layers. If you treat them properly, they will last for quite a long time. However, it is important to realize that it’s a consumable and the sheet can degrade through continuous use and lose some of its qualities.

Both these sheets have their own advantages – the powder-coated sheet will give your printed objects a really nice surface finish, while small parts printed from PLA might stick better to the smooth PEI sheet. Don’t forget that if you print with PETG on the smooth PEI sheet, you should clean it with Windex and not IPA, otherwise the print could stick too much to it. The best case scenario is, of course, if you own both sheets. Then you can simply switch between them depending on your current needs.

If you already have your powder-coated sheet, we’d love to hear your opinion and see your prints!

RE: Issues with heat bed adhesion and different steel sheets

I know the most heated discussions I've seen (and was in) have to do with the "Clean your plate and clean it my way!" admonition.

I don't believe that how you clean it, and what you use to clean it, is important as the fact that you do clean it and get it very free of oil, fingerprints, dirt, etc.

I found the following about powder coated sheets at

https://blog.prusaprinters.org/how-to-print-on-a-powder-coated-sheet_30178/

I have cleaned my powder coated sheet with dish soap - but only after the adhesion problem cropped up. I'm wondering if I need to buy a new sheet.

Print surface preparation

Do not apply any adhesive or separation layers on powder-coated sheets. All you need for a successful print is just a little bit of isopropyl alcohol (IPA) 90%+ as a degreaser (do not use Acetone! – see the explanation below). Apply IPA on a paper towel and clean the cold surface with it. If your print surface is hot, IPA will evaporate quickly and you won’t be able to clean the surface perfectly.

Calibration of the first layer

Do not forget that powder-coated sheets have a different thickness than smooth PEI sheets, therefore it is required to do the First layer calibration. Please note, that the improper adjustment of the first layer height can lead to damage of the sheet’s surface. This type of damage is not covered by your warranty!

While it’s true that it’s necessary to lower the nozzle more (compared to the smooth PEI sheet), it is important not to overdo it. The extruded filament should completely fill all gaps of the print surface while remaining smooth and flat on the top during the print of the first layer. If you set the nozzle too high, your object will not stick to the surface. If you set the nozzle too low, the extruded filament will either stick to the nozzle and peel off from the surface or (in the worst case scenario) you might damage your sheet.

My prints still don’t stick to the surface – what should I do?

If your print surface is perfectly clean, degreased with isopropyl alcohol and the first layer height is set up properly, your prints should (with only a few exceptions) stick to the plate very well. Small parts (especially printed from PLA) can detach due to a small contact area. In these cases, it’s better to use a smooth sheet that will ensure perfect adhesion. If you want to print small parts on a powder-coated sheet anyway, it is recommended to use a brim. The Brim function can be found in PrusaSlicer in the right panel, nex to infill density or under the tab Print settings – Skirt and Brim – Brim. Set the brim to at least 3 mm for better adhesion.

Do not use solvents other than IPA under any circumstances!

Acetone, in particular, must not be used on the powder-coated sheet! Using acetone makes the surface (Ultem) crack, and eventually, it peels off. Also, the powder-coated sheet is not waterproof. When exposed to high humidity, it corrodes and loses its properties. Therefore, do not clean the sheet with water. It is possible to do that only if you have truly tried everything mentioned and your objects still don’t stick to the surface. It could mean that you have sugar-based compounds on your sheet that can’t be dissolved with IPA.

Do:

Degrease the sheet with isopropyl alcohol (IPA) 90%+

Print without any adhesive or separation layers

Print supported materials (PETG, PLA, PC, CPE, PVA/BVOH, HIPS, Flex, nGen, Nylon)

Remove prints after the cooldown

Bend the sheet to remove printed objects

Don’t:

Use acetone and other agents

Print with adhesive or separation layers

Wash the sheet with water

Remove printed objects before cooldown

Use any instruments (spatula) to remove the printed object

Powder-coated sheets are a very good choice for printing all standard types of materials, without using additional adhesive layers. If you treat them properly, they will last for quite a long time. However, it is important to realize that it’s a consumable and the sheet can degrade through continuous use and lose some of its qualities.

Both these sheets have their own advantages – the powder-coated sheet will give your printed objects a really nice surface finish, while small parts printed from PLA might stick better to the smooth PEI sheet. Don’t forget that if you print with PETG on the smooth PEI sheet, you should clean it with Windex and not IPA, otherwise the print could stick too much to it. The best case scenario is, of course, if you own both sheets. Then you can simply switch between them depending on your current needs.

If you already have your powder-coated sheet, we’d love to hear your opinion and see your prints!

RE:

Sorry to say, but repeated fullquotes are a waste of time and I for one do not want to read 100 lines to find one or two new sentences. Back in the 90s fullquotes were considered just against netiquette.

Cheers

Chris

I try to give answers to the best of my ability, but I am not a 3D printing pro by any means, and anything you do you do at your own risk. BTW: I have no food for…