Is this resonance my bearings?

I get this rattle on the X at lower speeds and I'm unsure if this is the bearings that need packed or what but Ive replaced worn parts and triple checked all screws are tight.

I just picked up this prusa mk3s+ from work and put the muu2s on it. They ran the poor thing ragged till they destroyed the hotend then bought a whole different printer.

As I said I've replaced what parts needed it and get pretty good prints aside from some stringing or occasional ghosting but this noise bothers me most.

Thanks for any help!

RE: Is this resonance my bearings?

RE: Is this resonance my bearings?

We have no idea as we cannot hear what you are hearing.

Simple options,

1, Lightly lubricate the smooth rods

https://www.google.com/search?

https://help.prusa3d.com/en/guide/maintenance-tips_23200

https://help.prusa3d.com/en/article/i3-printers-regular-maintenance_2072

hopefully this will calm the linear bearings

2, check the motor is turning smoothly

3, check that the Idler is rotating smoothly.

If the problem persists try using a long screw driver as a Stethescope whilst the printer is moving.

you can touch the screw driver against the X axis end parts, and against the smooth rods, whilst the printer is running.

this may help you localise the noise

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: Is this resonance my bearings?

i have tried posting a video twice now and it wont seem to upload through the forum itself.

https://imgur.com/a/yssfsUt

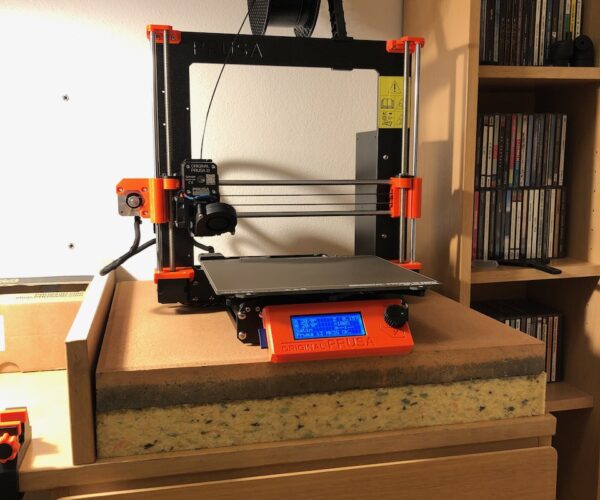

hopefully this works well enough. ignore the box im waiting for the plexiglass for the v2 enclosure

RE: Is this resonance my bearings?

It is coming from the extruder assembly like a rattling metal ball or something but the fans are snug and don't seem to be the source.

I used white lithium grease on the rods and have played with speed settings and it seems to be less apperant at higher speeds but my ghosting gets pretty bad

RE: Is this resonance my bearings?

Hi Ross,

From your short video clip, it sounds like the noise and vibration that the printer normally makes is being coupled into the printer support surface, which is acting as a sounding board and amplifying the noise.

After having the same experience, my printer now sits on a 500mm x 500mm x 50mm paving slab which has a 50mm foam block beneath it (see picture). That made a huge difference to noise levels!

I still notice a few odd resonances from the printer at certain X-axis & Y-axis travel speeds and at certain positions. My guess is that these are natural resonance modes of the printer structure that are being excited by particular 'step rates' of the axis motors.

If you can dampen down the overall noise levels by adding some mass/isolation under the printer, then the 'long screwdriver stethoscope' tip above may help to pin-point where the problem (if any) lies.

Cheers,

Tim

RE: Is this resonance my bearings?

Where could one find a slab like that? I'm worried something like that won't fit in the Ikea lack enclosure I've got in the works. I notice if I dampen the vibrations by hand on the extruder assembly the rattle is much less or even gone. I guess if it's just a noise I can live with it but now I'm unsure as to why I get so much ghosting despite tight belts and relatively slowish speeds

RE: Is this resonance my bearings?

As an experiment, try running the printer on something heavy and solid (i.e. lots of mass) - a solid floor will do if nothing else suitable is to hand. You will probably see a marked difference in noise levels.

I live in the Czech Republic and picked up both the slab and the foam at the local 'Bauhaus' DIY store. In the UK or US, a good builder's merchant selling construction materials should have something suitable. A garden center might also carry suitable materials normally used for garden paths, terraces etc.

I also have a LACK enclosure in the works. My slab is too large to sit in the space inside the table legs (45mm x 45mm I think). To get over that, I plan to create an intermediate riser section about 110-120mm high for the slab and foam to sit in. The riser section will have plates to support the legs of the upper LACK table so that they don't make contact with the slab (again to minimise coupled vibration and noise). The slab is heavy so I will probably strengthen the lower LACK table legs as well. I have a cunning plan for that!

Once I have it built-up, I plan to publish it on PrusaPrinters.

Cheers,

Tim

RE: Is this resonance my bearings?

That sounds interesting Tim I'd love see what you come up with as I'm sure I'll need to follow your lead. I did put a sort of softish thermal pad under the printer last night to test if it helped anything and surprisingly it helped a lot with noise. Today I'll go to Lowe's and look for a slab and foam. I hope this solution also fixes the ringing and ghosting issue! Thanks for all the suggestions so far I'll keep you all updated.

RE: Is this resonance my bearings?

Check your local home improvement center. I recently picked up a 16" x 16" x 1.75" concrete stepping stone that looks very similar. The 12x12 inch ones might work, but the printer's feet will be really close to the edges and the smaller size will have less mass which might make them less effective.

I originally was using some 3d-printed spring feet which helped a lot, but rapid back and forth movements still telegraphed a lot of noise into the next room. But using the concrete stone along with some non-slip feet under the slab (and standard feet on the printer) seems like it is a lot better (but it has only been about a day).

RE: Is this resonance my bearings?

The printed spring feet sound like something that would just break quickly or slide a lot I'll have to check that out. I'm a little concerned about being able to find a slab that is able to fit in the enclosure while also maintaining enough Mass

RE: Is this resonance my bearings?

Ok so i ran to the store and got what i could find and it has for sure helped with overall noise level BUT its really highlighted the bearings just need love all around. i will most likely end up replacing them entirely with the suggested misumi bearings. Again i bought this printer from my workplace after it had sat for months collecting dust with a broken hot end. They just ran it until it broke with zero maintenance so it would not surprise me if bearings are just not up to snuff anymore between dust, debris, lack of care, and hundreds of hours of print time.

RE: Is this resonance my bearings?

Progress then! New bearings will certainly do no harm at all. Probably worth doing X, Y and Z axes if you are going to strip the machine down. Lots of info on what to do here: https://help.prusa3d.com/en/tag/mk3s-2/

In your photo, I assume those are rubber tiles above and below the slab. It may seem counter-intuitive, but it is better to have all the foam/rubber below the slab so that the printer is able to couple as much vibrational energy as possible into the mass of the concrete. Ideally you would bolt the printer to the slab to provide the best possible coupling, but doing that is going to make printer maintenance more problematic.

Stefan at CNC Kitchen has a 2017 video on his YouTube channel about printer noise reduction - well worth a watch! He also explains why springy feet are not a good idea.

Cheers,

Tim

RE: Is this resonance my bearings?

Yep I think bearings will fix my problems at this point and now I'm worried my enclosure won't fit with a slab under the printer since I have the muu2s. Thanks for the tip on the rubber I'll probably end up having to lose the 2nd one anyway for the reason I just mentioned.

RE: Is this resonance my bearings?

No problem and very happy to share what I have picked-up on my own learning journey

I'll keep you appraised of my LACK enclosure progress - hopefully I can pick-up 4 tables from IKEA this week.

The build will be in three phases. Phase 1 will be to get the base and the riser section done and to move the printer on to that. Phase 2 will be the actual enclosure that sits on the riser section. Phase 3 will be filament storage on top of that. Aim is to make the top two sections removable making it easier to move around and to get quick access to the rear and sides of the printer (also hence the wheels).

Cheers,

Tim