Increasing printing speeds doesn't lower printing time

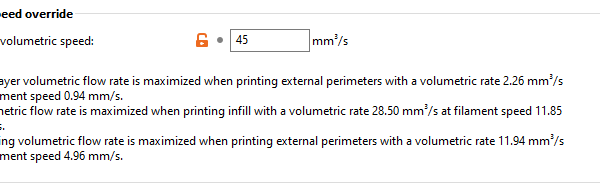

These are my current settings:

And the printing times for the benchy are:

I can't really seem to lower them for some reason though. I have increased them even by 200 and I got a 1 minute difference max. I've also increased the acceleration from 800 to 5000, and still no real difference. (I didn't actually print with those settings, I just wanted to see the time go down).

Why does this happen? Are there some hard limits? Please help, thanks!

RE: Increasing printing speeds doesn't lower printing time

@vanayad

Check "filament settings" -> "advanced" -> "Max Volumetric Speed"

Check "Filament Settings" -> "Cooling" -> "Slow Down if layer print time is below"/"Min Print Speed"

And, as always, save 3mf, ZIP it, and upload, for easier troubleshooting

Prusa i3 MK3S+ FW 3.11.0 (kit dec -20), PrusaSlicer 2.6.1+win64, Fusion 360, Windows 10

Please save your project (File>Save Project As). This will save a 3mf file with your model and a snapshot of all your settings. Then take the 3mf and ZIP it up and attach it. It must be zipped for the forum to accept the file.

With the 3mf we can work out what is the bottle neck.

However there are a couple of common things people miss. First is volumetric flow limits. This is set in 2 places, in the print setings but also in filament settings. Lowest value is used. This acts as a maximum of the amount of plastic extruded. You set it to match the rate of the filament/extruder combination. Doesn't matter how fast your speeds are set, once you hit the volumetric limit they get throttled.

Second are the filament cooling settings. There's also a minimum print time setting. On smaller objects where the layer times are short then the slicer will slow down to honour the minimum times. So you can have a massive speed set but on small things it doesn't matter.

it worked

Indeed, the slow down if layer print time is below X was the issue. Just lowering it a couple of seconds saved 10 minutes of print time.

My MVS is set to 45mm3/s (Volcano hotend) is that too low ?

@vanayad

Check "filament settings" -> "advanced" -> "Max Volumetric Speed"

Check "Filament Settings" -> "Cooling" -> "Slow Down if layer print time is below"/"Min Print Speed"And, as always, save 3mf, ZIP it, and upload, for easier troubleshooting

Your max used volumetric on that project is only 30mm anyway. If you reduce the slow down if print layer further to something like 5 seconds (which is my normal anyway) you can get it up to 34mm cubed a second on volumetric.

If you use the preview and change the view type you can see what you are getting. Can your volcano and filament actually handle 45 ? Just curious.

MVS

@vanayad

Can't see your MVS set to nothing other than "0"

"Filament Settings" -> "Advanced" -> "Max volumetric speed" is "0"

"Print Settings" -> "Speed" -> "Max volumetric speed" is also "0"

However, "Print Settings" -> "Speed" -> "Max print" is set to "80"

Prusa i3 MK3S+ FW 3.11.0 (kit dec -20), PrusaSlicer 2.6.1+win64, Fusion 360, Windows 10

MVS

@vanayad

Can't see your MVS set to nothing other than "0"

"Filament Settings" -> "Advanced" -> "Max volumetric speed" is "0"

"Print Settings" -> "Speed" -> "Max volumetric speed" is also "0"

However, "Print Settings" -> "Speed" -> "Max print" is set to "80"

I think it can do more than 45mm3/s, I've been told to simply triple the normal value (15mm3/s)

Your max used volumetric on that project is only 30mm anyway. If you reduce the slow down if print layer further to something like 5 seconds (which is my normal anyway) you can get it up to 34mm cubed a second on volumetric.

If you use the preview and change the view type you can see what you are getting. Can your volcano and filament actually handle 45 ? Just curious.

I would also expect the impact of higher speed to be more pronounced on large simple models compared to small complex models as for the latter the nozzle won't have time to accelerate to top speed.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

true story

It was a reduction of about 40h in time overall (from 100 hours to 60) over multiple prints.

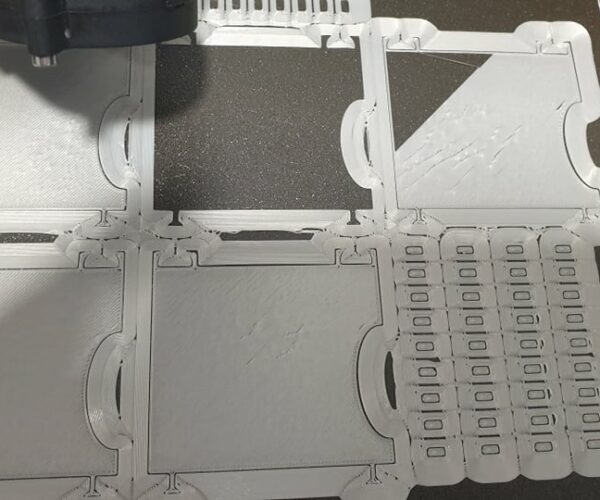

Now my question is about sticking. I have issues sometimes that the prints get warped on the ends though. Added a bigger brim but it didn't really help. I've disabled the first 10 layers of fan cooling and it seems to get a bit better, but any other tips would be great!

Should I add glue? Some other changes?

I would also expect the impact of higher speed to be more pronounced on large simple models compared to small complex models as for the latter the nozzle won't have time to accelerate to top speed.

The most common reason a brim “doesn’t help” is that as of PS 2.3 and earlier the elephants foot correction value. When you use elephants foot it moves all the first layer perimeters in to help counteract the squish you get from a good first layer. This is good and needed. The problem is that the brim is NOT moved in an equal amount. With the default value being 0.2 this can mean your part doesn’t even connect to the brim at all. Making it pointless. Other slicers use a separate offset value for the brim and move it in with the part. This is a much better way of doing it as the brim is always the offset value away from the part. From what I’ve been able to pick up I think they are changing this in PS2.4.

So you might want to check your settings and see if the brim is connected.

Of course having a really good squish first layer and an absolutely clean of grease bed also helps tremendously. I’ve done almost full bed pla prints without warping problems (display stands too) but similar prints in petg have warped. Not come away from the bed but actually stuck to the pei steel sheet and actually pulled the sheet away from the magnets the filament adhesion was that strong. I had to use some extra binder clips to keep the sheet in place.

Determining actual MVS

[...] My MVS is set to 45mm3/s (Volcano hotend) is that too low ?

That's going to depend on your nozzle and filament. I've documented a procedure that will let you identify the "red line" maximum rate you should use.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

mvs speed

For that volume, I'd need a 0.6 nozzle and a 370mm infill speed. That seems insanely high to me right now as I still have sticking issues. Thanks for the documentation though!

As you can see some parts are perfectly printed, and some others are the opposite... I don't know exactly what to do except in doing smaller area prints 🙁

[...] My MVS is set to 45mm3/s (Volcano hotend) is that too low ?

That's going to depend on your nozzle and filament. I've documented a procedure that will let you identify the "red line" maximum rate you should use.

Well from that its obvious that your brim isn't touching the part at all. That would suggest that either A) the elephants foot is set to high for your setup and B) you aren't squishing the first layer enough to get any elephants foot.

I think you are going to have to spend more time dialing in your first layer and getting that perfect before you can even look at anything else. Also the textured sheets aren't the best for pla. You have to adjust z down way more than you think. Also looking at some of the patchy no adhered areas that looks like classic non clean spots from grease, ie finger prints. What cleaning regimen do you use ?