I3 mk3s+ Not adhering first layer, or nozzle catching on 5th(ish) layer.

Hey! Any help is appreciated! Going on 40 hours of work on this printer.

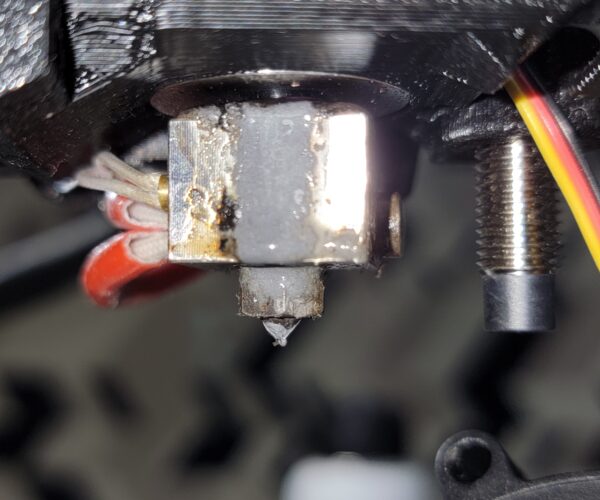

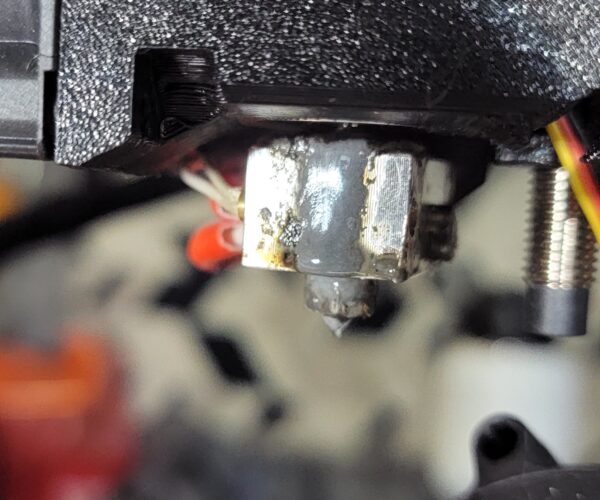

Built an i3 mk3s+, ran it for a week with no bad prints, all excellent quality with no fails (not even the very first one). Run a duplicate of a flawless velociraptor, come home, print came out sloppy but not the worst. Next day, nozzle is clogged. Fixed the clog, but now had bed adhesion issues. Used hot water and soap to clean, then the glue stick, then a little bit of iso to get a clean full surface stickiness. Now, my issues are either bad bed adhesion (first layer sticks except for the corners) or, 5th layer(ish) the nozzle catches the print and it's messed up. I switched out to a new nozzle (Genuine E3D Hardened Steel Nozzle .4mm (V6-NOZZLE-HS-175-400) on Amazon) and it worked a little bit. When the printer does a print, the little test strip in the front left is twice as thick if not more than the rest of the print and it always sticks to the bed flawlessly - how do I get the rest of the print to stick like that part? Not even any of the original Prusa models stick like that. But, aside from that, I thought maybe it was being under-extruded because the lines were so thin, so I took off the fan to get a better look at the heat block and the nozzle. The filament is oozing out over the side of the heat block (never messed with the heat block itself, just the nozzle, so I don't even know how to adjust that, but clearly I need to somehow. I just don't want to break anything.) I have looked at probably 75~ forum posts, 50~ videos. I performed a few cold pulls and they came out clean (after about the 3rd one) and I was more careful than any video I saw. Any advice at all will help, I'm pretty much at my wits end.

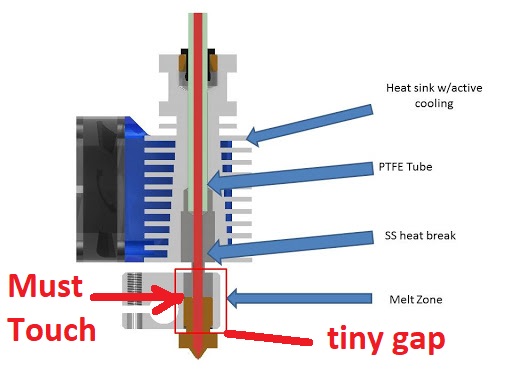

very likely you have a gap between the heatbreak and the nozzle, and the nozzle hex, is hard against the heatsink... this is a common error when peeps change nozzles...

what you now need to do, is to disassemble the extruder housing,

Loosen the nozzle whilst the nozzle is hot,

unscrew the hetbreak and heatsink assembly from the heatblock, cleam the waste filament off the heatblock and heat sink, then re assemble properly

this knowledge base document may help

https://help.prusa3d.com/en/article/changing-or-replacing-the-nozzle-mk2-5s-mk3s-mk3s_2069

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK