How to silence 3d printer

Hi guys, I’m interrested in you ideas how to improve silence in my room. All the time my 3d printer is as noisy as it is possible to hear it from cellar to ground floor on the other side of the house. I builded Enclosure v2 today and i need some recomendations. Will it help when i place some king of 10kg heavy tone brick and place printer on it ? Or some anti vibration pads ? I want it for night printing and it’s really difficult even watch some videos on internet while it is printing in my room. Thanks a lot for any help.

+ When i printed, i printed all of 1kg PETg and I think, that when filament sensor is 0 and it’s printing, print doesn’t stop. Am i right ?

Best Answer by bobstro:

Hi guys, I’m interrested in you ideas how to improve silence in my room. All the time my 3d printer is as noisy as it is possible to hear it from cellar to ground floor on the other side of the house. I builded Enclosure v2 today and i need some recomendations.

I recently moved my printer into my audio rack conversion. Like you, I found the printer resonating on the shelf surfaces creating more noise that carried much further than any mechanic noise on the printer itself. Following a couple of threads here, I just added a 17lb/7.7Kg paver this week. My understanding is that:

- Printer vibrations and the resultant ringing is due to the weight of the printer being insufficient to stop movement as the bed and extruder assembly are slung around. Weight dampens this effect. You want the printer and paver to be bonded as much as possible. I've used extended feet with felt pads between the printer and paver stone.

- Vibrations can be carried from the printer and paver into the large, resonating surfaces of the cabinet, both the shelves and sides. You want to isolate the printer and paver from the cabinet unless it is very rigid (unlike a Lack enclosure). I've put sorbithane pads under the paver to isolate it from the shelf.

- Rigidity in the cabinet itself is good. I've added corner braces and and looking into options to make it more rigid.

- Finally, the enclosure quiets simple mechanical noise.

So far, I'm pleased with the paver solution, but I do think you need to consider the linking of surfaces. CNC Kitchen has a couple of good videos on this topic. If the printer is isolated from the paver, you lose out on the benefit of the added mass for reducing printer resonances. If the paver is not isolated from the cabinet, it may transfer vibrations into the large cabinet surfaces, causing them to resonate.

Will it help when i place some king of 10kg heavy tone brick and place printer on it ? Or some anti vibration pads ? I want it for night printing and it’s really difficult even watch some videos on internet while it is printing in my room. Thanks a lot for any help.

My rack is currently open at the rear, but it reduces noise from 50-55dB while printing to 45dB. The air filter on low is much louder than the printer now. I can't hear it out of the room, although the rack is in the basement with a solid floor.

I'm still testing. Do search for "paver" here on the forums for more discussions and good info.

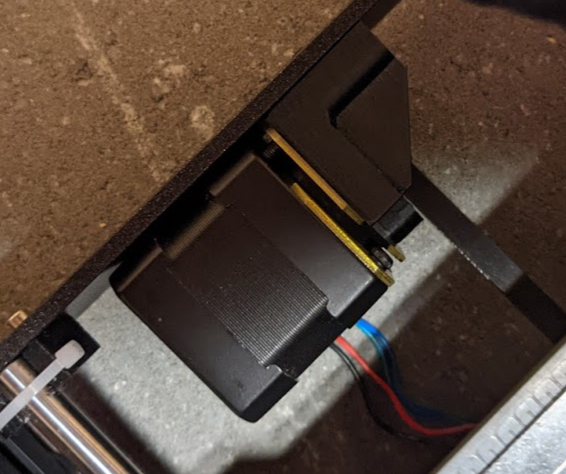

Here's a close up showing the painted paver. After 2 thick coats of Rust-Oleum auto primer/sealer, I coated the underside with PlastiDip rubber (probably a bit of a waste) and the top with Rust-Oleum to hopefully reduce any scratching from the heavy paver and make it look a little nicer. Here you can see some of the 8 Sorbithane feet. The shelf had a bit of a bow before, so I need to fix that:

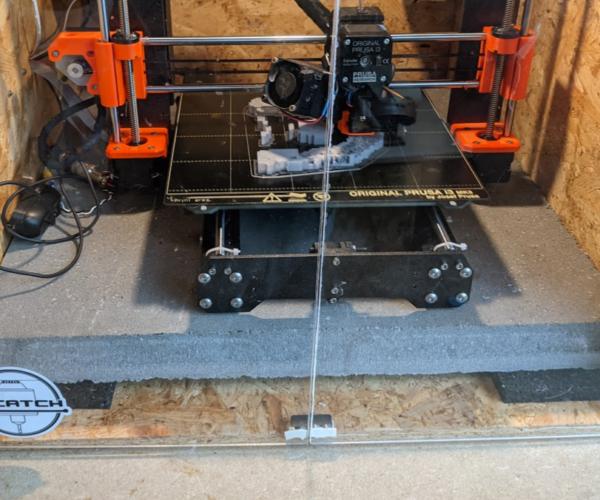

Here's the full printer view. Unfortunately, you can't see the felt padded feet under the printer:

RE: How to silence 3d printer

I print 24/7 and the noise is quite tolerable ... 50.4 dBA at 1 meter; and my cat made 62 dBA at 2 meters when he scratched at the door.

My printer is on a wood table, middle of room, no enclosure, running normal, not stealth. But most folk never grease their bearings so get a lot of excess noise and wear.

RE: How to silence 3d printer

Turn the printer off. It's the best way to silence it 🙂

But to be more serious, try to find the root cause. If it's a rattling sound coming from rods/bearings then usually it helps to reduce or increase the speed. Sometimes your build hits the resonance frequency with default speed settings. You can test it easily by rotating the knob during the print.

Select the silent mode on your printer. Usually it reduces already the noise.

Put the printer on the ground or something very heavy. Sometimes the standing ground is what amplifies the noise.

MK3/s can print pretty silent if met the mentioned requirements.

Often linked posts:

Going small with MMU2

Real Multi Material

My prints on Instagram

RE: How to silence 3d printer

Yep on the grounds it have 50-55dB. Anyway it resonance on floor in the house. I have aroud 200h printing hours there and I grease bearings every 2nd print with silicon spray, it make that noise only when the axis are connected to the motors. So only silent mode will help or reduce speed i think.

RE: How to silence 3d printer

Dump the silicone spray. That is not considered lubricating the bearings.

Do a proper bearing pack with Superlube or one of it's kin.

Thingiverse has a nice lube packer lid for the Superlube tube.

RE: How to silence 3d printer

Silicon ... nice hard surface for the bearings to surf on. Add a drop of clean engine oil (e.g., 0-20w synthetic) on each side of each of the bearings - that should help until you get time to tear things apart and properly lubricate the mechanics.

Regarding resonance with the table and stand: some find adding concrete pavers under the printer help. Or quality speaker isolation pads.

RE: How to silence 3d printer

Also: I may be fooling myself, but I added Rubber/felt floor protectors to my Ikea Lack enclosure and it seems to help. This is on a wood floor and seems to reduce acoustic coupling between the enclosure and the floor:

https://www.amazon.com/gp/product/B06XG8GHYD/ref=ppx_yo_dt_b_asin_title_o03_s00?ie=UTF8&psc=1

RE: How to silence 3d printer

And what kind od libricate so you use guys ? Exactly ? Can you please give me web adress where to buy it ?

RE: How to silence 3d printer

Well since I seem to be pushing Amazon, this is what I got. And my Thingiverse nozzle fits it:

RE: How to silence 3d printer

The lack enclosure will resonate unless you have weight to dampen it. oil/grease on the bearings and rods are a key part of reducing noise as suggested above.

You did not mention what the Lack Enclosure is on, hard floor / table or carpet but that will affect noise too. If it is not on carpet you may want to get some felt pads or carpet squares to put under the legs for sound muffling

I have a 3 lack stack V2 enclosure on a carpet floor and use two pavers as weight on the bottom shelf for stability. Just outdoor 17"X17" concrete pavers from a home supply store. I have a piece of 1 inch Marble directly under the printer. I find that shelf liner, the rubbery kind that you can buy in a roll for $5 and cut to size both underneath and in between the pavers and the marble nicely quiets any resonance so that I can have overnight prints running without any noise disturbances. I bought black and have it between the printer and marble and marble and Lack. Added benefit that it keeps things from sliding around.

Strange women, laying in ponds, distributing swords, is hardly a basis for a system of governance!

RE: How to silence 3d printer

Hi guys, I’m interrested in you ideas how to improve silence in my room. All the time my 3d printer is as noisy as it is possible to hear it from cellar to ground floor on the other side of the house. I builded Enclosure v2 today and i need some recomendations.

I recently moved my printer into my audio rack conversion. Like you, I found the printer resonating on the shelf surfaces creating more noise that carried much further than any mechanic noise on the printer itself. Following a couple of threads here, I just added a 17lb/7.7Kg paver this week. My understanding is that:

- Printer vibrations and the resultant ringing is due to the weight of the printer being insufficient to stop movement as the bed and extruder assembly are slung around. Weight dampens this effect. You want the printer and paver to be bonded as much as possible. I've used extended feet with felt pads between the printer and paver stone.

- Vibrations can be carried from the printer and paver into the large, resonating surfaces of the cabinet, both the shelves and sides. You want to isolate the printer and paver from the cabinet unless it is very rigid (unlike a Lack enclosure). I've put sorbithane pads under the paver to isolate it from the shelf.

- Rigidity in the cabinet itself is good. I've added corner braces and and looking into options to make it more rigid.

- Finally, the enclosure quiets simple mechanical noise.

So far, I'm pleased with the paver solution, but I do think you need to consider the linking of surfaces. CNC Kitchen has a couple of good videos on this topic. If the printer is isolated from the paver, you lose out on the benefit of the added mass for reducing printer resonances. If the paver is not isolated from the cabinet, it may transfer vibrations into the large cabinet surfaces, causing them to resonate.

Will it help when i place some king of 10kg heavy tone brick and place printer on it ? Or some anti vibration pads ? I want it for night printing and it’s really difficult even watch some videos on internet while it is printing in my room. Thanks a lot for any help.

My rack is currently open at the rear, but it reduces noise from 50-55dB while printing to 45dB. The air filter on low is much louder than the printer now. I can't hear it out of the room, although the rack is in the basement with a solid floor.

I'm still testing. Do search for "paver" here on the forums for more discussions and good info.

Here's a close up showing the painted paver. After 2 thick coats of Rust-Oleum auto primer/sealer, I coated the underside with PlastiDip rubber (probably a bit of a waste) and the top with Rust-Oleum to hopefully reduce any scratching from the heavy paver and make it look a little nicer. Here you can see some of the 8 Sorbithane feet. The shelf had a bit of a bow before, so I need to fix that:

Here's the full printer view. Unfortunately, you can't see the felt padded feet under the printer:

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: How to silence 3d printer

The lack enclosure will resonate unless you have weight to dampen it. oil/grease on the bearings and rods are a key part of reducing noise as suggested above.

You did not mention what the Lack Enclosure is on, hard floor / table or carpet but that will affect noise too. If it is not on carpet you may want to get some felt pads or carpet squares to put under the legs for sound muffling

I have a 3 lack stack V2 enclosure on a carpet floor and use two pavers as weight on the bottom shelf for stability. Just outdoor 17"X17" concrete pavers from a home supply store. I have a piece of 1 inch Marble directly under the printer. I find that shelf liner, the rubbery kind that you can buy in a roll for $5 and cut to size both underneath and in between the pavers and the marble nicely quiets any resonance so that I can have overnight prints running without any noise disturbances. I bought black and have it between the printer and marble and marble and Lack. Added benefit that it keeps things from sliding around.

I have it on parquets, i was thinking about that carpet and some antivibration pads unter it. But I think, when i also mix 10kg paver with antivib. pads and some kind of carpet under it, it will be silent anought.

RE: How to silence 3d printer

Hi guys, I’m interrested in you ideas how to improve silence in my room. All the time my 3d printer is as noisy as it is possible to hear it from cellar to ground floor on the other side of the house. I builded Enclosure v2 today and i need some recomendations.

I recently moved my printer into my audio rack conversion. Like you, I found the printer resonating on the shelf surfaces creating more noise that carried much further than any mechanic noise on the printer itself. Following a couple of threads here, I just added a 17lb/7.7Kg paver this week. My understanding is that:

- Printer vibrations and the resultant ringing is due to the weight of the printer being insufficient to stop movement as the bed and extruder assembly are slung around. Weight dampens this effect. You want the printer and paver to be bonded as much as possible. I've used extended feet with felt pads between the printer and paver stone.

- Vibrations can be carried from the printer and paver into the large, resonating surfaces of the cabinet, both the shelves and sides. You want to isolate the printer and paver from the cabinet unless it is very rigid (unlike a Lack enclosure). I've put sorbithane pads under the paver to isolate it from the shelf.

- Rigidity in the cabinet itself is good. I've added corner braces and and looking into options to make it more rigid.

- Finally, the enclosure quiets simple mechanical noise.

So far, I'm pleased with the paver solution, but I do think you need to consider the linking of surfaces. CNC Kitchen has a couple of good videos on this topic. If the printer is isolated from the paver, you lose out on the benefit of the added mass for reducing printer resonances. If the paver is not isolated from the cabinet, it may transfer vibrations into the large cabinet surfaces, causing them to resonate.

Will it help when i place some king of 10kg heavy tone brick and place printer on it ? Or some anti vibration pads ? I want it for night printing and it’s really difficult even watch some videos on internet while it is printing in my room. Thanks a lot for any help.

My rack is currently open at the rear, but it reduces noise from 50-55dB while printing to 45dB. The air filter on low is much louder than the printer now. I can't hear it out of the room, although the rack is in the basement with a solid floor.

I'm still testing. Do search for "paver" here on the forums for more discussions and good info.

Here's a close up showing the painted paver. After 2 thick coats of Rust-Oleum auto primer/sealer, I coated the underside with PlastiDip rubber (probably a bit of a waste) and the top with Rust-Oleum to hopefully reduce any scratching from the heavy paver and make it look a little nicer. Here you can see some of the 8 Sorbithane feet. The shelf had a bit of a bow before, so I need to fix that:

Here's the full printer view. Unfortunately, you can't see the felt padded feet under the printer:

Nice one :O First i need to find something for bearing 😀 It might help anought, then i will try things i wrote before 🙂 Thanks for help.

RE: How to silence 3d printer

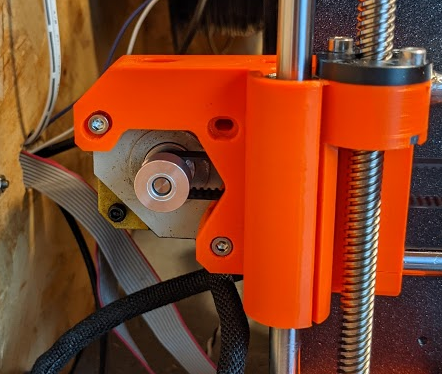

Just to know, I'm the only one using stepper motor dampers?

In my case, the printer is in enclosure in wood (OSB) on top of a pavel with wash machine rubber to remove vibration on the bench, but is not enough.

Yesterday I add two stepper motor dampers, one on the Y axe and the second on the X, the result is incredible. The dampers remove tones of vibrations and by extensions noises. Don't know at this stage if the print result get a better quality (ghosting) but at least the noises are dramatically reduced (approved by my wife :))

RE: How to silence 3d printer

you can try using dry bearings. i am using vesconite superlubes. makes a difference. harder to adjust but when finished it very nice.

RE: How to silence 3d printer

And what kind od libricate so you use guys ? Exactly ? Can you please give me web adress where to buy it ?

Put the paver on a piece of 40mm+ thick medium density foam cut to the same size as the paver. This will isolate the paver from the surface it's sitting on.

As for your bearings, do yourself a HUGE favour and do the following:

If you dont already have some, order a bottle of 100% (or as close to) isopropyl alcohol. You need it anyway and 5L is cheap.

Super Lube 21030 (the part number is important!) Not sure where you're located, but you should be able to find a local supplier.

https://www.mektronics.com.au/super-lube-multi-purpose-grease-3oz-tube.html

Then download and print these these:

Linear Bearing Grease Cap

https://www.thingiverse.com/thing:1128781

Linear Bearing Grease Cap Lid

https://www.thingiverse.com/thing:1134114

While your waiting for the alcohol and grease to arrive, do all the printing. Use PETG, a 0.4 nozzle and 0.2mm layer height and 0.42 extrusion width for all extrusions. This makes the threads and openings accurate.

Pull all of your linear bearings out. Put them in an airtight container with enough isopropyl alcohol to cover them by about 5mm. Give them a gentle tilt around, let them sit for 5-10mins and repeat tilting them around. Do this for 40-60mins to get rid of all the OEM oil.

Pull them out and shake out all the excess alcholol and then let them stand on their end on a couple of sheets of paper towel for about 30-60mins.

Get a bunch of paper towel sheets torn off in preparation as your fingers are going to get messy and it's a pain to get the towel after you have grease everywhere. 🙂

Get the grease cap you printed, put it on the tube, line the slots up with the balls in the bearings, slide the bearing on and then squeeze the tube till some grease starts to come out the top of the bearing. Do this to all the bearings.

Slide the bearing onto one of the smooth rods one at a time and slide it up and down about 20-30 times. You can wipe of the excess grease.

Repack the bearings again and repeat - this is important as I found out the hard way and hard to tear down my printer a second time to repack them. It's needed to work the grease through all of the balls.

Put your printer back together, run a full XYZ, belt and first layer calibration; knock the top off a cold one and enjoy the beautiful silence of properly LUBRICATED bearings! 🙂 👍

RE: How to silence 3d printer

I had a similar experience when I put my MK3s in one of those laser cut wooden enclosures (with the built in HEPA/Carbon fan). I'd already quieted the printer down considerably with Squash Ball feet mod, but as soon as I put it in the enclosure all of the noises got louder, even with enclosure closed. To make things worse, the enclosure fan resonated louder than the printer due to being mounted on a thin plywood wall.

Long story short ... heres the three things to do to quiet the Mk3s.

1. Squash Ball mod on the printer - gets the noise transmitted through the frame out of the picture.

2. Cut four squash balls horizontally about 25% of the ball (watch out, they are hollow and have some liquid in them typically). The flat keeps them from rolling. Put these four squash balls under your enclosure with the printer in it, flat side down, then set enclosure on the rounds. They don't roll unless you get crazy.. - Gets all of the resonation in the enclosure.

3. Secure the Y axis stepper motor to the back frame with a long Zip tie - position the zip tie at the edge of the motor at the back left of the printer, around the outside frame, and tighten that baby down. - This gets rid of most of the Y carriage noise that this printer makes.

After that, if the printer is still making more noise than you like, close the door on the enclosure 😉

RE: How to silence 3d printer

@olivier-4

Whoah ... where to get those?

RE: How to silence 3d printer

I'll second the use of isolation methods to separate the printer from the surface it sits on. After putting my printer in a Lack enclosure, it got very loud. The isolation tests I tried with foam under the printer absorbed all of the vibrations that were amplified by thin/light Lack enclosure.

Like @dan-rogers, I ended up with squash ball feet. The difference between Dan's and my approach is that I used whole squash balls. I have no idea which is better. I went for simple -- I used these feet ( https://www.prusaprinters.org/prints/48010 ) to hold the squash balls. What I liked about this design is that I did not need to disassemble anything on the printer and the feet were also compatible with the PSU mount.

There are lots of squash ball foot designs on the Prusa Prints and Thingiverse sites. Take a look for a design that appeals to you.

RE: How to silence 3d printer

@egar

To clarify - I used the standard whole squash balls under the printer and four _additional_ squash balls (cut as described) under the enclosure. The round balls under the bottom of the enclosure were like bearings and it rolled around. So I cut flats in the balls and that, as they say, was history.