How to remove shreded screw

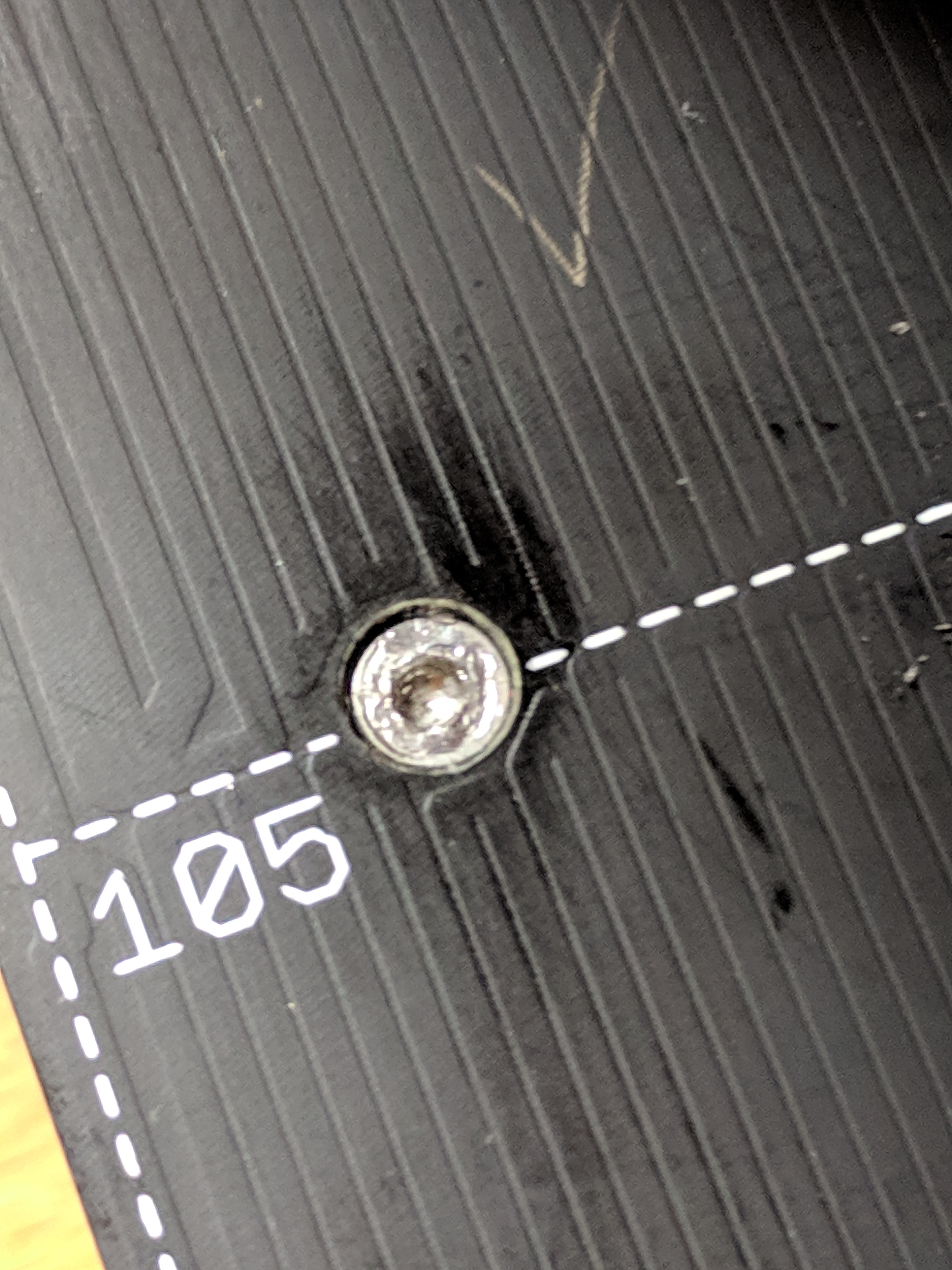

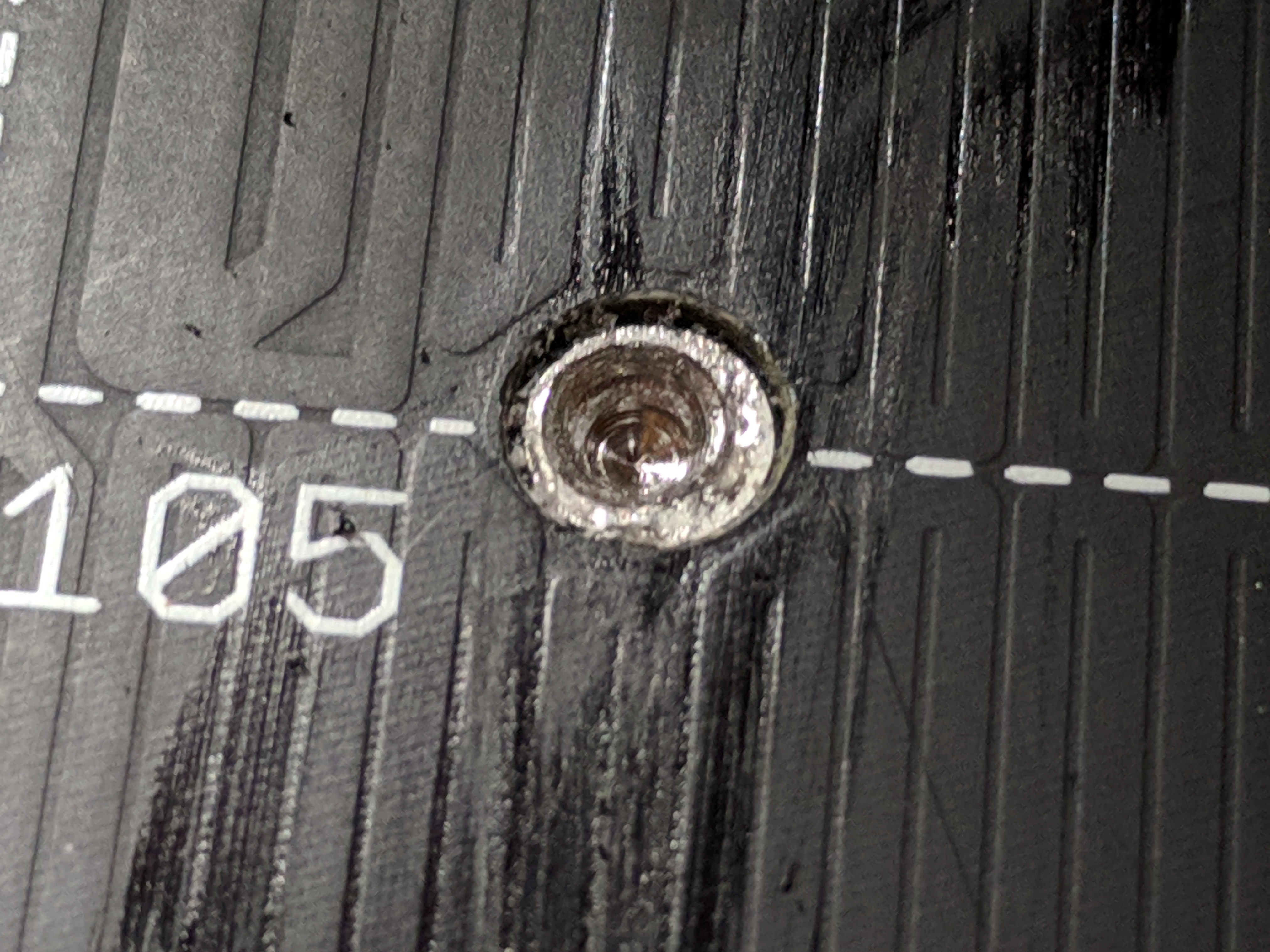

I find myself in a bit of a pickle - I really don't want to get a drill but I'm running out of options. On my MK3 I need to adjust the bed height - I have found the calibration not being good enough to provide an even surface. I tested with a digital indicator and there's about 0.35mm differences on the extreme, so I wanted to adjust the bed screws a bit to get it closer to level. All went fine till I got to the screw you see in the picture. It would NOT budge and now it looks like it does.

I've tried with super-glue and different size/form screw bits but when they "bite" the screw it just comes apart when I try to turn it.

I would like ideas - in particular ideas that doesn't endanger the actual heat bed.

Re: How to remove shreded screw

small chance you can get a torx to fit. OR if you have a dremel you could just cut a line in the screw and try a flat head screw driver.

maybe heat up the bed. that might loosen things up abit.

I have a Prusa,therefore I research.

Re: How to remove shreded screw

Looks like a job for a screw extraction bit.

Re: How to remove shreded screw

Looks like a job for a screw extraction bit.

this size will work with 3mm screw hex socket

https://www.amazon.com/dp/B000Q60UOO/ref=sxts_kp_bs_1?pf_rd_p=8778bc68-27e7-403f-8460-de48b6e788fb&pd_rd_wg=Tqym2&pf_rd_r=9J6THSA67W906JRSP0H4&pd_rd_i=B000Q60UOO&pd_rd_w=ZWuHx&pd_rd_r=f48e3a3b-d939-4641-927c-38c83c5a42a5&ie=UTF8&qid=1549337650&sr=1

Re: How to remove shreded screw

Looks like a job for a screw extraction bit.

this size will work with 3mm screw hex socket

https://www.amazon.com/dp/B000Q60UOO/ref=sxts_kp_bs_1?pf_rd_p=8778bc68-27e7-403f-8460-de48b6e788fb&pd_rd_wg=Tqym2&pf_rd_r=9J6THSA67W906JRSP0H4&pd_rd_i=B000Q60UOO&pd_rd_w=ZWuHx&pd_rd_r=f48e3a3b-d939-4641-927c-38c83c5a42a5&ie=UTF8&qid=1549337650&sr=1

Yeah - I actually have a similar set but all it does is remove the head - no traction because the screw is so little. I'm afraid if I bore it out the tapped windings in the hole where the screw goes will be destroyed.

Re: How to remove shreded screw

If you have a standard Grabit set that is what happens... you can't use the smallest #1 of the standard set even though it looks like it should work; you need this micro set for something as small as a 3mm hexhead countersunk screw as used on the heat bed

Re: How to remove shreded screw

If all else fails and this is NOT the center screw, you could cut through the standoff and screw with a dremel and cuf-off wheel.

I'd do that only as a last resort because it's going to be really messy. You do not want stray metal grindings in your bearings.

Looking ahead for AFTER you sort out the bolt business..

You can do what has become known as the nylock method of mechanically leveling the bed.

Alternatively, you can do as I have and grind custom length brass standoffs for each bolt position to achieve better flatness. Doesn't take but a few hours of careful grinding and filing. Advantage is I can quickly remove my heatbed - just have to keep track of which standoff goes in which position.

Also, get 7 x 7 mesh bed leveling firmware. That compensates for more bumps than 3 x 3.

Re: How to remove shreded screw

If all else fails and this is NOT the center screw, you could cut through the standoff and screw with a dremel and cuf-off wheel.

I'd do that only as a last resort because it's going to be really messy. You do not want stray metal grindings in your bearings.

This may be the only option. It's not the center screw but not one of those in the corners either. Nothing seems to be able to "catch" and move the screw and as you can see by now there's quite a hole that just gets deeper. I'll need to see if I have any spare stand-offs before I start this little adventure.

Looking ahead for AFTER you sort out the bolt business..

You can do what has become known as the nylock method of mechanically leveling the bed.

Alternatively, you can do as I have and grind custom length brass standoffs for each bolt position to achieve better flatness. Doesn't take but a few hours of careful grinding and filing. Advantage is I can quickly remove my heatbed - just have to keep track of which standoff goes in which position.

Also, get 7 x 7 mesh bed leveling firmware. That compensates for more bumps than 3 x 3.

Since it's the same bolts and I've been able to make 0.1/0.2mm adjustments on the other screws by tightning or loosing them I hope I don't need to make custom parts here. That would indicate that the foundation is out of whack and perhaps that's a bigger issue if that's the issue.

For now I've attached a digital indicator and I'm pretty sure once it's homed in, the 3x3 bed leveling should be just fine?? Note, every time I've updated firmware I've had leveling issues *sigh* - and I really thought I had it tuned in last month. It however seems there's some movements after long prints (30h+ prints). What seemed to have been level days before became almost to the point where there was no bed adhesion. And as I stated above I've measured more tha 0.3mm height difference on the extremes.

So if you or others have final ideas on how to attack this screw as you can see in the pictures, I'll probably leave this project be until the weekend. Here's what I've tried:

* Extractor bits of different sizes (M2, M3 sizes - even one that says 0-2 in sizes (very thin one))

* Superglue (just a drop) - cracks the moment I apply pressure to turn it

* Heating the bed

* Different bit sizes to see if a flat head would catch. Even when I can feel a catch, the screw bits just seems to break off when there's a catch. Granted, there isn't much to catch on.

Thanks for the suggestions so far.

Re: How to remove shreded screw

you are very close to properly drilling out that broken screw.... if you decided to get a Micro GrabIt set then use it with the smallest or next smallest size and it should come right out

if you just want to get it out with out getting that set then keep going with a 2.5 mm drill or a number 40 drill and with a dental pick get any remaining threads in the hole out. then take a 3mm x .5 tap and clean up the threads if you have to go up a size let us know what size drill you had to use to clean out the hole and we can advise. but this way you will need those sizes of drills and then the 3mm tap as well which will cost as much as the Micro GrabIt and these gadgets are some thing that get used with all the modern gadgets that use the tiny fasteners.

I am concerned about what caused this SS screw to gall in the Aluminum frame to this extent. these bed screws should bot be tightened more than one newton or 10 inch pounds when installed and galling should not happen at this torque levels

Re: How to remove shreded screw

you are very close to properly drilling out that broken screw.... if you decided to get a Micro GrabIt set then use it with the smallest or next smallest size and it should come right out

if you just want to get it out with out getting that set then keep going with a 2.5 mm drill or a number 40 drill and with a dental pick get any remaining threads in the hole out. then take a 3mm x .5 tap and clean up the threads if you have to go up a size let us know what size drill you had to use to clean out the hole and we can advise. but this way you will need those sizes of drills and then the 3mm tap as well which will cost as much as the Micro GrabIt and these gadgets are some thing that get used with all the modern gadgets that use the tiny fasteners.

I am concerned about what caused this SS screw to gall in the Aluminum frame to this extent. these bed screws should bot be tightened more than one newton or 10 inch pounds when installed and galling should not happen at this torque levels

I had one that seized up and had to be drilled out, but it wasn't the threads in the Y carriage, it was the head in the heatbed. There was enough variation in the screw head size and the heat bed holes that one of them, when tightened down sufficiently to secure the bed, wedged itself in with enough friction that I couldn't get it out without stripping the head. I ended up having to drill it out. Once the head was off, the I was able to unscrew the shaft with my fingers.

Re: How to remove shreded screw

That is a good point William, if the op removes the whole bed their might be enough of the screw above the frame to grab with pliers or vice grip and just twist it out... that would be the best move given the picture provided. stainless steel fasteners into Aluminum is a place where you have to be concerned with galling

Re: How to remove shreded screw

you are very close to properly drilling out that broken screw.... if you decided to get a Micro GrabIt set then use it with the smallest or next smallest size and it should come right out

Nope - that's the one I used. Well, I tried others too, but I've tried the smallest and the one above it (M2 and M3) of that set, and it never gets traction or the screw is set too hard for the little traction it gets for it to work.

Re: How to remove shreded screw

Left handed drill bits tend to work better than screw extractors, if you can get them in the right size. They'll bite in but since they cut in the same direction the screw turns to come out, when they bite and grab, out comes your screw!

Re: How to remove shreded screw

crap, I didn't notice that was you peter.121... do you want me to try to stop over with some tools, or did it get it loose?

at this point it looks so bad, you might want to find a flat head screw driver just the right size to tap it with a hammer and try to get it lodged into the screw head.

I have a Prusa,therefore I research.

Re: How to remove shreded screw

That is a good point William, if the op removes the whole bed their might be enough of the screw above the frame to grab with pliers or vice grip and just twist it out... that would be the best move given the picture provided. stainless steel fasteners into Aluminum is a place where you have to be concerned with galling

I'm running out of time to work on this, this weekend. But I don't want to leave this hanging. The reason I haven't just removed all the other screws is that I'm sure it will result in the heat-bed cracking/breaking.

The shredded screw is actually set pretty deep - my guess is that it's about 1mm or more insert and lower than the surface of the heat-bed. So I cannot just cut the head off with a pair of pliers. The only option would be to remove the head using a drill which would most likely result in parts of the heat-bed being removed too, or as someone else suggested cut the screw from under neeth and remove all the other screws, take off the bed and try to recover the frame where the screw goes in.

I'm definitely interested in learning why it's stuck too. My guess is tension between the stand-off and the heat-bed is too high and hence is locking it in by simply pushing the head very very deep into the bed (also matches seeing the screw so far in). In which case, I need to inspect the heat-bed once I get it off to see if can be recovered, and perhaps I need a small shim to help strengthen the hole before putting things back together. Gahhh - I cannot wait till I get time to do that - late next week once I'm back from travel /me crosses fingers, bangs on wood etc

Again, thanks for all the suggestions I've recieved here. I wish I had more time to mess with the printer this last week but alas it's not been possible.

Re: How to remove shreded screw

crap, I didn't notice that was you peter.121... do you want me to try to stop over with some tools, or did it get it loose?

at this point it looks so bad, you might want to find a flat head screw driver just the right size to tap it with a hammer and try to get it lodged into the screw head.

Nope - I haven't had a chance to "play" with this since mid last week where I tried a very very small extractor without any luck (no traction).

There's quite a bit of way from MN to VA - and I'll be in NC all this week so that's even further. I think I have the tools - my problem is time. Worst case would be having to use the dremmel to cut it off from under the bed.

I've tried the flathead, bigger/smaller manual screw drivers etc. and all I get done is scrape more metal off the screw. That's what the extractors do too. I'm definitely cautious - so afraid I'll hit/destroy the bed itself with a careless tool. Which means I do not like the idea of trying to use something to cut a grove for a flathead to sit in - I know that will destroy part of the bed surface too. So I'm more inclined to just cut the stand/screw under the bed - I have the tools to do that too, but I agree that finding a way to protect the bearings under the bed is important if I choose to do that.

Re: How to remove shreded screw

ahh looks like you moved, that's too bad. at least you missed out of the cold that hit us not long ago

I have a Prusa,therefore I research.

Re: How to remove shreded screw

You will need the Y carrage off and on a hard surface to get a decent push on the screw. Try some of thses in the vid

Re: How to remove shreded screw

A quick update - and again a thanks to everyone who had suggestions. And sorry for a bit of a long delay in my replies - I travel quite a bit for work, and it's been a bit of a struggle to find the time and energy to fix this mess I created.

But - SUCCESS - I finally got the screw out! I didn't have to cut the stand-off but I acutally purchased spare standoffs as I prepared to "take it down". I tried all kinds of screw removal tools like Grabit - I had an old set that claimed to be for M3 and M4 screws, and I got a smaller one with 1-4 - those are a lot smaller than my M3/M4 set so "somebody is lying". I focused on the very small bits, and that may have been the issue - while they dug into the screw there was never any traction. I tried to use a dremmel to cut a grove but it's set too deep to really make that a precise cut - it was too shallow for my small flat-head screw-driver to catch it.

What worked was putting the hot-plate under clamp pressure. A small plywood sheet to protect the bed allowed me to ally enough presure that the screw wasn't totally stuck. Then the #4 Grabit from the smaller set went straight in and grabbed it right away. It was grabbed so good I needed pliers to unseat the screw from the extractor after-wards 🙂

Now I need to replace the screw and find a way to avoid over-tightning the screws. This mess was one of my own making. I've made adjustments to the bed over the last year to make it "flatter' and print evenly on the whole bed - not just in the middle. And doing that I overtightened this screw. I knew I had messed up when during tightning last time the bit came off the screw and I realized how low it was set. I realized that instead of making that section lower I would have kept it higher, and adjusted the rest of the bed to follow. Well long lesson learned.

Note - the 6x6x3T standoffs were hard to find. I had to go to a real hardware store that sells every kind of screw, bit, nut and bolt possible, including custom made to find something that would match. Not even ebay had any hits. Just curious if others have had similar issues getting a single replacement part for the MK3.

For the casual reader - compared to my other printers the MK3 is a dream to manage, work on and adjust. While nothing is perfect - this was a self-made mess and it took me weeks because well, I only worked on it for 30 minutes a week or so. With the help/suggestions here I found a solution. I would never have guessed that my extraction bits were not what they claimed to be without this forum.

So thanks again to everyone that helped.

Re: How to remove shreded screw

i used a torque driver at 10 inch pounds for these screws and I also lapped the spacers to be the same length as the shortest provided this brought my bed to level enough the the mesh bed system worked quite well; but to be able to get a good first layer across the whole bed right to the edges I am using the 7x7 modified firmware .