How to control the hot end with a ESP32 or Raspberry Pi Pico

Hello

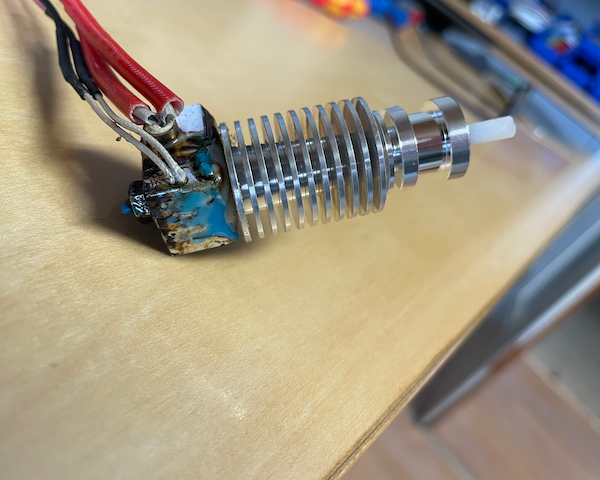

I screwed up my hotend by having the nozle to loose. So it was leeking filament all over. See pictures.

I fixed it with a new hotend which is working fine. Now I'm wondering if there's a way to clean the old one. It would be nice to have spare one.

I found some posts sugesting to mount into the printer, heat it up an try to get rid of the molten filament. I'm not to keen on taking the working printer appart and mount the old hotend just to clean it and redo the whole thing including calibration.

I have some ESP32 and Raspberry Pi Pico and also some power supplys at hand. I'm wondering if I could use them to heat up and control the hotend. This would also have the advantage that the hotend is much easier to access and clean if it's not mounted in the printer.

So I'm looking for a datasheet about the electronics of the prusa i3 mk3s hotend or instruction how i can control the temperature with a micro controller.

RE: How to control the hot end with a ESP32 or Raspberry Pi Pico

this might be easier with a Ramps board and Arduino Mega

as the heater infrastructure is already present on the Ramps, and pre configured programs exist to load up on the ramps

Use Pronterface, and a USB Cable to control the extruder heat commands

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: How to control the hot end with a ESP32 or Raspberry Pi Pico

By far the easiest is to take a heat gun to it.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: How to control the hot end with a ESP32 or Raspberry Pi Pico

By far the easiest is to take a heat gun to it.

Good point. I have one with temperatur regulation at hand.

What about the cables? Guess I would have to shield them somehow from the hot air. Any ideas?

RE: How to control the hot end with a ESP32 or Raspberry Pi Pico

this might be easier with a Ramps board and Arduino Mega

as the heater infrastructure is already present on the Ramps, and pre configured programs exist to load up on the ramps

Use Pronterface, and a USB Cable to control the extruder heat commandsregards Joan

That basically means: Build an other 3D Printer controller. This would work for sure. But buing a a ramps board and a arduino mega ist about the same price as a new hotend. From the economical point of view this does not makes sense to save one hotend.

RE: How to control the hot end with a ESP32 or Raspberry Pi Pico

I've done that a couple of times. If you use some common sense and don't overdo it, the wired should be fine. Focus the heat on the side away from them.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: How to control the hot end with a ESP32 or Raspberry Pi Pico

You would also need a MOSFET to power and control your heater cartridge without frying your RasPi.

I'd give the heat gun a go, you just have to soften the filament up to be able separate the parts thereafter you can apply more heat to the heat block and the nozzle to get them clean.

If at first you don't succeed, skydiving is not for you.

Find out why this is pinned in the general section!

RE: How to control the hot end with a ESP32 or Raspberry Pi Pico

is a raspberry pi plus mosfet board plus custom programming, cheaper than ramps and mega?

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE:

Well, a Raspberry Pi Pico or ESP32 dev board is about $5. A mosfet board is $2 at aliexpress. A ramps board and an arduino mega clone is about $40.

And as I mentioned in my question. The Pico or ESP32 are already on my desk.

RE:

If you have access to an electric cooker (won't work in hob), while she (or he in these enlightened times) who must be obeyed isn't looking, heat the largest element, lay the block (sans heat break) in the element, it get hot real quick.

RE: How to control the hot end with a ESP32 or Raspberry Pi Pico

I have cleaned the Prusa heatblock cold, using a box knife, a small vise, and a lot of care to avoid getting hurt. Filament (and other residue) scraped right off. I finished it off with a fine sanding block and a small wire brush. I then chased out the threads using a junk nozzle.

I have never (yet) had the need to work on a Prusa hot end while it's hot and out of the printer, but I have done so with the Ultimaker using a lab bench supply as a current source (as opposed to a voltage source) and a digital thermometer to check the temperature.