hotend trouble

I purchased a MK3 kit more than a year ago. Have been printing for about 100 hrs since then.

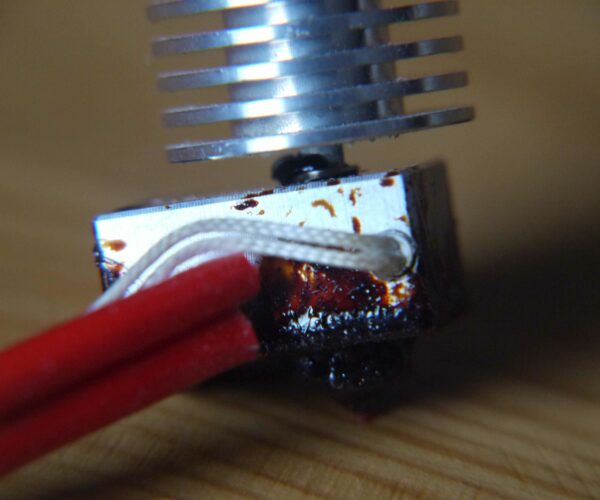

Decided to upgrade frrom MK3 to MK3S and ordered the upgrade kit. I have started the deconstruction work the other day. When I had removed the complete hotend this part looked very strange as you can see on the attached pictures. Note that filament plastic also came out between the cooling body and the heating box. All PET-G parts were printed without problems before.

The only strange thing was a lot of ultrathin threads like spiderwebs were found all around the parts. This phenomenon appeared already a long time ago but it did not disturb me because after cleaning all parts were perfect.

The question is wether the part can be cleaned and repaired or does it have to be replaced ? And what should I do to prevent this happening again ?

Thanks for any comment,

Juergen

The question is wether the hotend can be cleaned and

jayvee

RE: hotend trouble

Good news is that it can be cleaned off as it is just burnt on cooked plastic. Heating it up and very carefully using a brass wire brush will remove it. Just be very very careful around the thermistor and heating element. In fact if you can remove them first that would be safer.

The bad news is that it means your nozzle has been leaking all this time and looks like it wasn't properly tightened against the heatbreak. This causes plastic to seep out both above and below the heat block. From your pics I can see some has come out the top too as well as the botttom being covered.

Did you by any chance happen to have the occasional small black mark on your prints ? I would expect so as the burnt plastic will drip off onto the parts when at temp.

After cleaning follow the E3d assembly / nozzle replacement guide to the letter without missing out ANY steps. The improperly tightened nozzle is also highly likely to have been contributing to your fine stringing issue too.

If its reassembled correctly you wont have any more plastic leaking out. Keep an eye on it and if you notice ANY around the top between the heat block and heatbreak or around the bottom of the heatblock/nozzle then you didn't assemble correctly so need to do it again.

RE: hotend trouble

Do be prepared to replace the heatbreak, thermistor and heater cartridge as they may be impossible to remove without damage if they've really cooked in there. The heater block may be recoverable, but I'd have a spare of that as well in case anything is bonded permanently in it.

In addition @neophyl's excellent recommendation to read up on the E3D nozzle swap procedure, consider using a silicone sock and maybe even a coated nozzle to keep that hotend clean! Otherwise odd bits can fall into your prints at bad times. Make sure the nozzle hex does NOT touch the heater block after a nozzle swap. There should be a visible gap if you've done it correctly.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: hotend trouble

@bobstro

@neophyl

thank you so much for the helpful advices.

I first heated the hotend with 15 Watts and then took of as much plastic as possible with different soft tools. Then I was able to remove from the block the heater and the sensor. Afterwards I made the block look like new with 400 waterproof sanding paper on a level surface. Then put back the guts and started the laborious assembling of the MK3S E-axis unit. The whole procedure saved me a lot of money for a new complete hotend.

I thoroughly followed yor advices and hope a mess like this will not happen again. So thank you again and good luck, Juergen

jayvee