Hotend leakage, heatbreak issue - How to proceed 🤔

Hi,

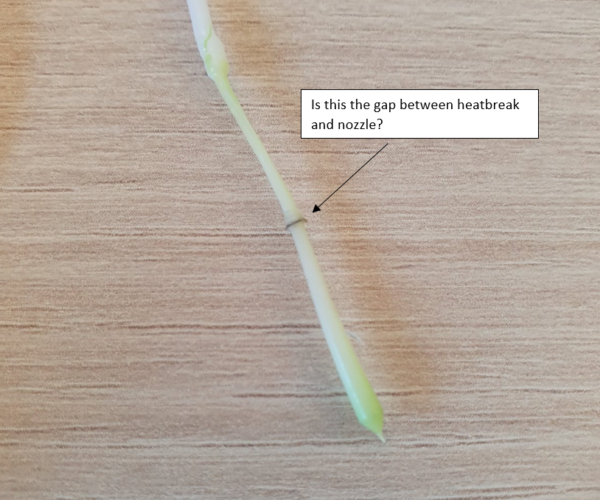

two days ago I ran into first problem after changing the nozzle (0.4 -> 0.6). Now - after several assemblies - it looked like the heatbreak "turned" a little out of place as I hardly had a nice gap between the nozzle and heatblock. It looked ok to me at the bottom end of tolerance.

Next print went just fine. No leakage, no blobs but the nozzle partly clocked somehow as I noticed when unbloading the filament which was slightly worn from extruder gear rubbing.

I decided to clean the nozzle and did all steps from the guide "Clogged nozzle/hotend". Filament flow was fine after this.

Afterwards I tried to bring the heatbreak in place by this procedure I found here and worked for me in the past:

1. Cut zip locks that hold your heater wires or you may run out of slack

2. Heat to filament temperature and unload filament. Remove fan shroud shift parts cooling fan aside.

3. Increase temp to 285C

4. Use wrench to hold heat block in place

5. Unscrew nozzle completely.

6. Reach into empty nozzle hole and clean out old filament debris with counterclockwise twisting of q-tip.

7. Use wrench to twist heat block 45 degree onto the heat break. (viewed from bottom would be clockwise.) This should advance heat break a little further into heat block.

8. Hold heat block in its temporary 45 degree position with wrench

9. Install nozzle. It should now impinge against end of heat break a bit sooner. Tension to two fingers tight (still at 285C)

10. Let nozzle temp cool

11. Turn off printer

12. Undo hot end cover and straighten out the entire E3d hotend assembly to bring heat block back into normal alignment. The entire assembly including the cooling fins should be rotated, not just the heat block.

13. Redo zip ties.

Well this looked fine and I didn't use much force.

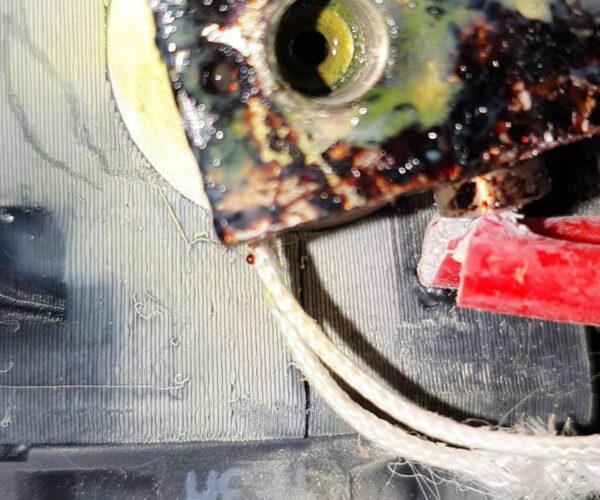

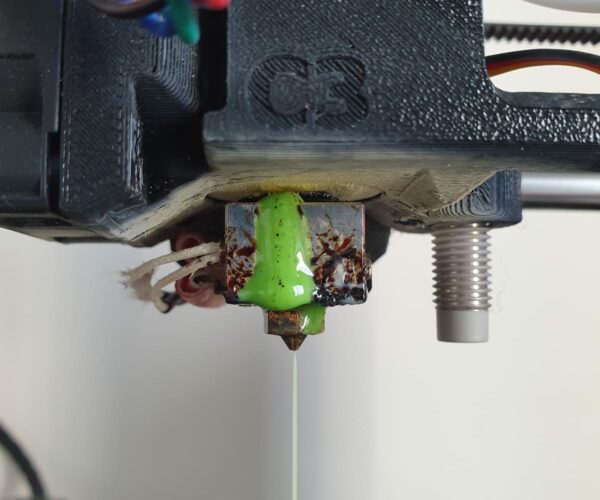

My next short print of ~3 hours came out flawlessly (black PLA). The problems visibly started with a 15 hour print (green PLA) that ended in a crash caused by "blob" - allthough the leakage already started before (see picture 'leakage' with black filament above the heatblock). I attach some photos of the mess.

Finally my questions 🤓

What went wront and what should I do next?

- Does it look like "damaged beyond repair"?

- Was the heatbreak to nozzle contace not tight enough?

- May I try the quoted procedure above again?

- Should I disassemble the hotend and reassemble it afterwards?

Sorry for the long post. I just wanted to provide all information. Hope you have a good advice.

Greetings

Daniel

RE: Hotend leakage, heatbreak issue - How to proceed 🤔

If it is leaking, there is a gap somewhere. Most likely between the nozzle and heatbreak.

I would replace the heatbreak and nozzle and clean the other one up.

--------------------

Chuck H

3D Printer Review Blog