heatblock seems lose after changing nozzle

Hi,

I recently tried to change my nozzle, I followed the video but struggled removing the nozzle and had to apply more force than i expected. I've successfuly changed the nozzel now but am concerned the heatblock does tighten sufficently anymore. Is this amount of play normal? I've tried unscrewing and rescrewing the nozzel and re-tightening the heatblock a few times but always with the same results. Any advice would be greatly apprecitaed.

Many thanks

A

RE: heatblock seems lose after changing nozzle

Hi Andrew,

this is not normal,

could be,

1, nozzle hard against heatblock, not touching heatbreak,

2, heatbreak loose in heatsink or

3, heatsink loose in housing.

item 1 is the worst... likely to lead to leaking filament

all of them mean you have to dissassemble part of the extruder housing,

have a look at the nozzle, is the hex nut screwed tight to the heatbreak?

If yes, heat the nozzle and loosen the nozzle from the heat break then continue (Letting the nozzle cool first!!!)

next dissassemble the extruder housing

https://help.prusa3d.com/en/guide/how-to-change-a-heatbreak-heatsink-heaterblock-mk3s-mk2-5s-mmu2s_16104

this knowledge base article covers changing various parts, but you are most interested in seeing which parts are loose and tigntening them CORRECTLY!

Pay particular attention to the section on the correct way to fit the nozzle...

It is worth reading this article and the fitting a new nozzle article, together. so that you definitely get the job done correctly.

If the top of the heatsink was actually loose in the housing, you could consider putting a piece of tape around the top part or stetching an elastic band and fitting it in the recess of the top mounting boss, before re assembly, you only need enough to tighten the fit a little bit. then when you reassemble your parts everything should be nice and tight, and in the right places.

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility. Location Halifax UK

RE: heatblock seems lose after changing nozzle

@joantabb

Thank you so much Joan for such clear and comprehensive help. I will try this tonight. Thanks again. A

RE: heatblock seems lose after changing nozzle

@joantabb

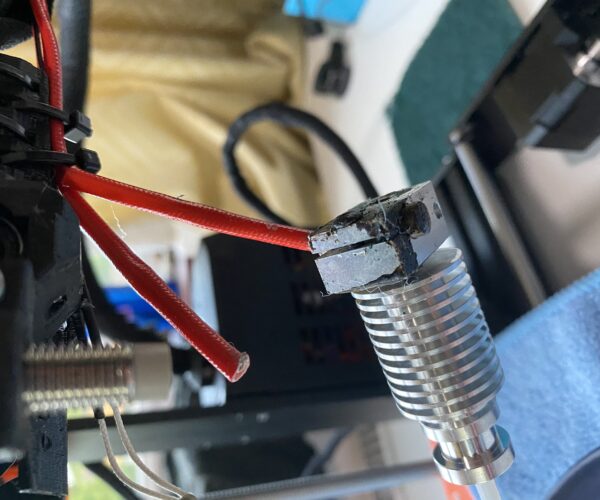

Ok sooo this has not gone to plan.

I disassembled the extruder without too much difficulty. I decided to try an detach the heatblock to examine it further. However I struggled to remove the heater screw (which I now think has melted PLA in it) and after a slip of the allen key have managed to snap the heater cable. Is there anyway I can fix, or even order a replacement - I had a look on the site but can't see any.

RE: heatblock seems lose after changing nozzle

Hi Andrew,

that needs a replacement heater cartridge! 🙁

where are you?

UK? US? elsewhere?

I can't see the heaters on Prusa either,

E3D online seem to have them

https://e3d-online.com/standard-heater-cartridge

for a mk3 you need 24 volts, 40watts

I suggest that you get a spare thermistor as well, because they are fragile, and you may damage it when you try to remove the heater

If you get two heaters and all goes well, you will have a heater and thermistor in stock for when you get a Blob of doom... 🙂 (It will happen, just a matter of time. and if you have difficulty removing the blob you may well end up damaging the heater and thermistor, having one in stock will save you time

Looking at the top of your heat block, it looks like your nozzle and heatblock are not tightened properly together.

If you have problems dissassembling the parts, you can heat them with a hot air blower or in the oven...

Please use heatproof gloves to prevent burns.

If you have filament in the heatblock threads as I suspect you do... and you have the equipment, you can clean the threads with a tap and die in M6 thread...

if you don't have a tap and die, but you have a spare 6mm bolt and 6mm nut, you can cut a slot through the nut and screw that on to the heatbreal 6mm thread to scrape the plastic off ( the same trick should work on the nozzle threads, and you can cut a slot across the bolt threads and use that to scrape the heatblock threads clean

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility. Location Halifax UK