Heatbed damaged by spring steel sheet

Dear,

having some serious issue with the heatbed coating.

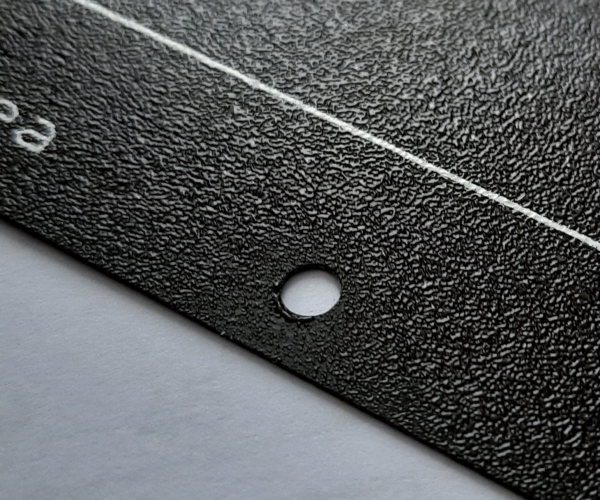

It seems to be that the powder coated spring steel sheet, which has two small holes at the front, damaged the electrical insulation of the heatbed.

So when switching on the heater, there are sparks like you´re welding something at the holes.

How to handle this?

Tried to put some protecting varnish on the blank metal - but not working pretty good at all.

How can this happen, I mean you sometimes have to align the spring steel sheet a little bit, this shouldn´t destroy the heatbed at all.

Thank you,

Arndt

Best Answer by JoanTabb:

is there a sharp burr around the hole?

if there is, try and remove the burr

then put some clear varnish over the repair on the build plate, and the scrape on the build plate.

mail varnish is good!

Joan

RE: Heatbed damaged by spring steel sheet

is there a sharp burr around the hole?

if there is, try and remove the burr

then put some clear varnish over the repair on the build plate, and the scrape on the build plate.

mail varnish is good!

Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: Heatbed damaged by spring steel sheet

No there is no sharp burr around the hole, so it´s more strange that the heatbed is damaged.

Anyhow, gonna try to find some varnish and try this.

Is the heatbed protected against overload?

So, what will happen if the varnish breaks, again some sparks at the defective part, can I burn down my office or damage the PCB of the printer?

Or will printer detected the overcurrent and disable the heatbed?

Thank you in advance,

Arndt

RE: Heatbed damaged by spring steel sheet

I first used an protective vanish for electronic components- unfortuntly this doesn´t work cause it melted when getting warm. Fortunatly I easily could remove with Isopropyl.

Then I used an vanish based on acryl and put a single layer of PVC insulation tape (coroplast) which can be used up to 110°C.

Heated up the heatbed to 110°C for some minutes and it looks good.

Anyway, for safety reason the next print I´ll do when I´m near the printer (panic).

Thank you and have a nice evening.

Kind regards,

Arndt

RE: Heatbed damaged by spring steel sheet

I have the same issue, except for the sparking. It started within the first week of getting the printer and the printer is only a few months old now .

No discernable burs on the textured build sheet.

I'm going to contact support as it's a bit disappointing and is getting worse with time.

RE: Heatbed damaged by spring steel sheet

At daylight I had an closer look on the steel sheet - even if it is not sharp, seems to be that this small "wall" can damage the heatbed, as the magnets are quite strong..

Just saw this using an camera - my eyes are not good enough anymore 😉

Removed this with sandpaper - so even if you can´t feel with your fingers, doublecheck it

RE: Heatbed damaged by spring steel sheet

I have small areas of damage on a couple of my beds. They still work so no issue to me.

--------------------

Chuck H

3D Printer Review Blog

RE: Heatbed damaged by spring steel sheet

@charles-h13

Then you´re one of these who had luck 🙂

Mine started to produce smoke and light arcs - no fun at all

Started new print today with the vanish and insualtion tape, hope it will last.

RE: Heatbed damaged by spring steel sheet

@markarndt

Mine works fine despite damage. The damage is superficial on mine.

--------------------

Chuck H

3D Printer Review Blog