Gluey substance coming out next of the extruder

Hi there,

I just noticed that there is some kind of of gluey white melted substance coming down next to the extruder. This also just ruined my print. Can somebody tell, where this is coming from? I assume I have to disassemble some parts of the extruder right?

Best Answer by Neophyl:

Its likely the grey filament then, if you were to disassemble the extruder you would find that the only white in there would be the ptfe liner, thats in an area that doesn't get hot and you would need a LOT of temperature to break it down. If the ptfe has gotten that hot the rest of your extruder plastic parts would be a mess too. I suppose it could be thermal paste if you used any but that wouldnt harden when cool so it would be a paste when you touched it cold. It doesn't look like that's the case to me.

Remove your fan shroud so you can inspect the top of the heat block with a good light.

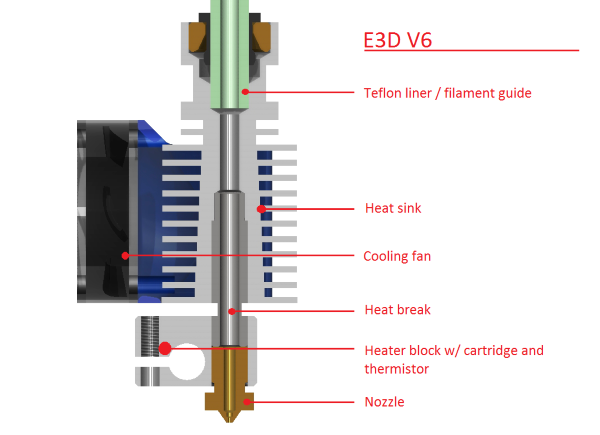

The whole point of the gap advice is so it can be tightened inside the heatblock to mate with the heatbreak. If the nozzle is already flush against the heatblock you cant know its touching the heatbreak. When doing a new assembly its normal to screw the nozzle into the heatblock leaving the gap size you want. Then screw in the heatbreak from the other side to meet it finger tight. Then screw the heatsink onto the heatbreak and finally fit that into the extruder.

You can then do a hot tighten to make sure its sealed at temperature. All that is done for you by Prusa. However you have to be very careful using Prusa's nozzle swap process as they would have you rotate the heatblock. Thats just as likely the position the heatblock further down if you arent careful. I follow E3D's instructions in which you don't do that. You simply hold the block with a suitable metal tool and unscrew the nozzle. At no point do you need to move the heatblock.

You do have to be careful of the wires to the heater and thermistor but thats true of any maintenance action anyway.

Its also another reason to always use good quality E3d spec nozzles. Some of the cheaper ones don't have the threads as long as with the proper ones. As such you can screw them in all the way and still not get a seal unless you also reposition the heatbreak further down. That moves the whole heatblock assembly up. This can position it too close to the plastic parts, move it out of alignment with the fan shroud, requires adjusting the pinda probe position in its bracket etc. Basically its a pain, just to save a few a small amount of money.

RE: Gluey substance coming out next of the extruder

That's melted filament. Its caused by an improperly fitted nozzle, when there's a tiny gap left between the top of your nozzle and the heatbreak inside the heatblock. The pressure forces plastic up the treads and out the top of the block, where it pools and then eventually drips down. Depending on how much of a gap it can take hours/days to happen so you may think you fitted a nozzle correctly when you havent.

RE: Gluey substance coming out next of the extruder

@neophyl

Ok thanks. Yea I actually had an issue before with my nozzle not being screwed in thight enough. I find it quite tricky to find the balance of thighten it up and leaving a small gap between nozzle and heater block at the same time.

But are you sure it´s just filament? Because I have actually never printed something in white so far (only black, orange a little bit grey in the beginning)

RE: Gluey substance coming out next of the extruder

Its likely the grey filament then, if you were to disassemble the extruder you would find that the only white in there would be the ptfe liner, thats in an area that doesn't get hot and you would need a LOT of temperature to break it down. If the ptfe has gotten that hot the rest of your extruder plastic parts would be a mess too. I suppose it could be thermal paste if you used any but that wouldnt harden when cool so it would be a paste when you touched it cold. It doesn't look like that's the case to me.

Remove your fan shroud so you can inspect the top of the heat block with a good light.

The whole point of the gap advice is so it can be tightened inside the heatblock to mate with the heatbreak. If the nozzle is already flush against the heatblock you cant know its touching the heatbreak. When doing a new assembly its normal to screw the nozzle into the heatblock leaving the gap size you want. Then screw in the heatbreak from the other side to meet it finger tight. Then screw the heatsink onto the heatbreak and finally fit that into the extruder.

You can then do a hot tighten to make sure its sealed at temperature. All that is done for you by Prusa. However you have to be very careful using Prusa's nozzle swap process as they would have you rotate the heatblock. Thats just as likely the position the heatblock further down if you arent careful. I follow E3D's instructions in which you don't do that. You simply hold the block with a suitable metal tool and unscrew the nozzle. At no point do you need to move the heatblock.

You do have to be careful of the wires to the heater and thermistor but thats true of any maintenance action anyway.

Its also another reason to always use good quality E3d spec nozzles. Some of the cheaper ones don't have the threads as long as with the proper ones. As such you can screw them in all the way and still not get a seal unless you also reposition the heatbreak further down. That moves the whole heatblock assembly up. This can position it too close to the plastic parts, move it out of alignment with the fan shroud, requires adjusting the pinda probe position in its bracket etc. Basically its a pain, just to save a few a small amount of money.

RE: Gluey substance coming out next of the extruder

@neophyl

I'm not the OP but thank you for this excellent info. I've yet to change a nozzle on my MK3S+ but after watching Prusa's video guide to doing so, I was caught up on the idea of rotating the heatblock, for the very reason you describe, which is that it could cause a slight repositioning of the heatbreak, which in turn can cause all of the other alignment to be thrown off. When it does come time for me to change a nozzle, I'm going to (carefully) clamp the heatblock in place as I uninstall and replace the nozzle, which assuming the lengths of the threaded shafts of both nozzles are the same, should keep a gap from forming between the heatbreak and nozzle, and avoid the gooey mess described above.

RE: Gluey substance coming out next of the extruder

What exactly is the purpose of rotating the heat block? I've always omitted that step, and the machine has not blown up, at least yet.

RE: Gluey substance coming out next of the extruder

@jsw

From my understanding of it, the purpose is to temporarily loosen the connection between heatblock and heatbreak, to avoid damaging the heatbreak (which is a thin, fragile component) during removal and replacement of the nozzle.

RE: Gluey substance coming out next of the extruder

@neophyl

I'm not the OP but thank you for this excellent info. I've yet to change a nozzle on my MK3S+ but after watching Prusa's video guide to doing so, I was caught up on the idea of rotating the heatblock, for the very reason you describe, which is that it could cause a slight repositioning of the heatbreak, which in turn can cause all of the other alignment to be thrown off. When it does come time for me to change a nozzle, I'm going to (carefully) clamp the heatblock in place as I uninstall and replace the nozzle, which assuming the lengths of the threaded shafts of both nozzles are the same, should keep a gap from forming between the heatbreak and nozzle, and avoid the gooey mess described above.

Where can one find said video?

Would like to watch it.

Are there any other Prusa videos that are worth watching, the manuals are excellent, but I do like a video 😀

(Watched Joseph Prusa's new user video)

Tank you very much!

RE: Gluey substance coming out next of the extruder

@neophyl

Hey, thank you so much! That was indeed really helpful and useful. I have indeed already changed the nozzle once by following the Prusa guide. And now that I know it, I am pretty sure this exact thing you described happened to me. Also, the rotated heat block melted a bit of the casing because I rotated too far. So next time I will definitely use the method of E3D.

I will try to clean everything up and retighten the nozzle. So am I right that if I notice that my nozzle gets all the way in and doesn´t leave a gap I would have to screw down the heat break? And that probably requires a disassembly of the extruder?

RE: Gluey substance coming out next of the extruder

@clarmrrsn

For the reasons discussed above, you'll want to ignore the part about rotating the heatblock.

RE: Gluey substance coming out next of the extruder

What exactly is the purpose of rotating the heat block? I've always omitted that step, and the machine has not blown up, at least yet.

I saw a write-up somewhere that suggested it was to ensure that the heatbreak is inserted into the block far enough to prevent tightening the nozzle up snug against the heater block. Don't recall where I read it, and I too ignored it after a few tries early on.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Gluey substance coming out next of the extruder

It is common problem with newcomers. It is easy to fix. I still get it on occasion.

--------------------

Chuck H

3D Printer Review Blog

RE: Gluey substance coming out next of the extruder

I watched the video, and read the knowledge base article.

Is using a torque wrench still recommended for nozzle tightening, and if so should this be done with or without rotating the heat block, or both ways?

Also can someone clarify this statement from the KB article.

Our service- and assembly-team use a torque wrench rated for 1 - 5 N m, and tighten the nozzle with a force of 2.5 N m (Newton Meter).

How can one use a wrench rated for 1.5nm and tighten to 2.5nm?

Tank you very much!

RE: Gluey substance coming out next of the extruder

Dash not "." Rated for 1 TO 5 Nm, which means its adjustable, so they have it set to 2.5nm.

Basically don't rotate the heatblock. There's no need to do so and the E3D instructions don't do it that way. Given that they designed the extruder parts and supply them to Prusa personally I'd follow their instructions.

RE: Gluey substance coming out next of the extruder

@neophyl

Lol

OK I'm a tool.

Yeah that makes a bit more sense, maybe should put my glasses on next time.

Tank you very much!

RE: Gluey substance coming out next of the extruder

@clarmrrsn

Lol, there are a few people I could use that description with. You aren't anywhere near there.

RE: Gluey substance coming out next of the extruder

I designed a gadget to make the whole process a lot easier...

https://www.prusaprinters.org/prints/41652-heatblock-clamp-for-nozle-change-mk3s

RE: Gluey substance coming out next of the extruder

@xanthe

Pretty neat idea.

--------------------

Chuck H

3D Printer Review Blog

RE: Gluey substance coming out next of the extruder

@xanthe

A very good idea.

Tank you very much!

RE: Gluey substance coming out next of the extruder

I do the same with an adjustable wrench/spanner. I've not removed the fan duct to change a nozzle yet, except in the case where I've been doing a rebuild for other reasons.