Fried heatbed power connection cable - reason?

Our company has 4 prusa running now and the one that has this problem is the very first one we assembled.

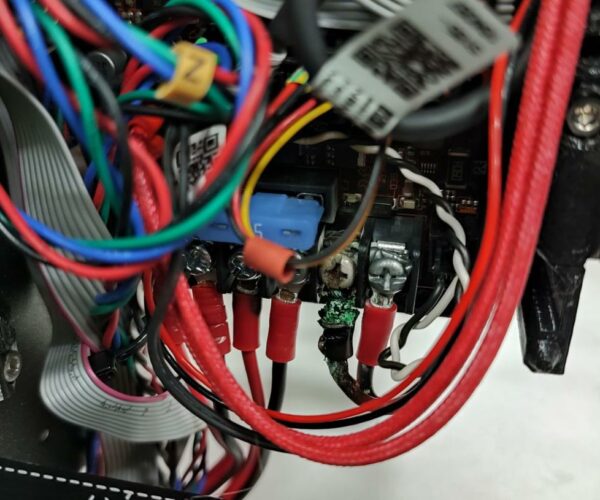

The problem is shown in this picture here:

In case you didn't notice, the heatbed power cable is badly melted. Also one other power cable from the PSU was also slightly blackened. The burned probably didn't happened today. As there was no plastic burning smell at all. But I did notice smell of burned plastic a couple of weeks ago. I could not locate the source then and attributed it to burn fillament at the hotend. Now I know it's probably then the cable was melted.

How I found out:

I was printing stuff normally today. Wasn't satisfied with the print at the beginning. Stopped the print then started a new print.

Then superPINDA stopped working. As it was probing for bed leveling the hotend just pressed all the way down on the steel sheet, and the following message is shown.

"Bed leveling failed. Sensor didn't trigger Debris on nozzle? Waiting for reset."

Puzzled. I restart the machine. Only had the same thing to happen. I went through trouble shooting. After a few minutes I suspect the cables on the Einsy board was somehow loosened. That's when I decided to open it up, and found out the heatbed cable was fried/melt.

What may not be the cause:

Loosen cable: As this was our very first machine assembled, everything was double triple checked. We took our time and the assembly was 3 days long. We followed everything to the tee. That includes properly securing the cables. I can say with confidence that the cables were correctly connected and were tightened properly.

Skipped washer: The power connection was screwed under the washers as instructed.

Stretched cable: There is enough room for the cable and it's not stretched or overly loose

Other connection issue: I opened up the other end of the heatbed connection, and nothing wrong there.

What may be the cause:

Upon looking online I found out this is more common then I thought:

It was suggested in these thread that there are three possible cause: loosen cable, over tightened cable, bad crimped. Since I am confident that the cables are correctly tightened, I am inclined to believe that it's some badly crimped cables.

How the machine is performing now:

Everything except the superPINDA is working properly, including the heatbed. It heats up just fine. Again I check the connection on the Einsy board: the superPINDA cable is secured proper with no abnormality.

Fried connector

I have seen this from 2 causes -

- a loose connector on either end

- shorted connector

--------------------

Chuck H

3D Printer Review Blog

Bad crimp

There has been at least one case reported where the problem was a bad crimp.

Depending on the damage you might get away with cleaning up the terminal block and screw and either cutting the old wire and adding a connector or possibly replacing the wire. Joan has some silicon covered wire she recommends so perhaps she will jump in with the info.

jwv

Resistance isn't futile

These melt because of resistance. Resistance between the wire strands and the spade connector (bad crimp possible cause), resistance between the spade lug and the motherboard terminal (screw grew loose - possible causes no crush washer, not fully tightened when installed, torque applied to wire loosened connection while closing Einsy box), and resistance between trace on motherboard and terminal connector (bad solder joint). In rare cases material incompatibility between the metals involved in the connectors (cheap poorly manufactured wire/spade lug assembly).

One More thing

I would take pictures and clean it up and take more pictures. Contact support via chat and ask if ti needs replaced. You might be at risk of a fire.

--------------------

Chuck H

3D Printer Review Blog