font control knob will not depress

The LCD control knob on my PRUSA printer will not depress (click). It does however rotate. Any ideas?

Best Answer by Diem:

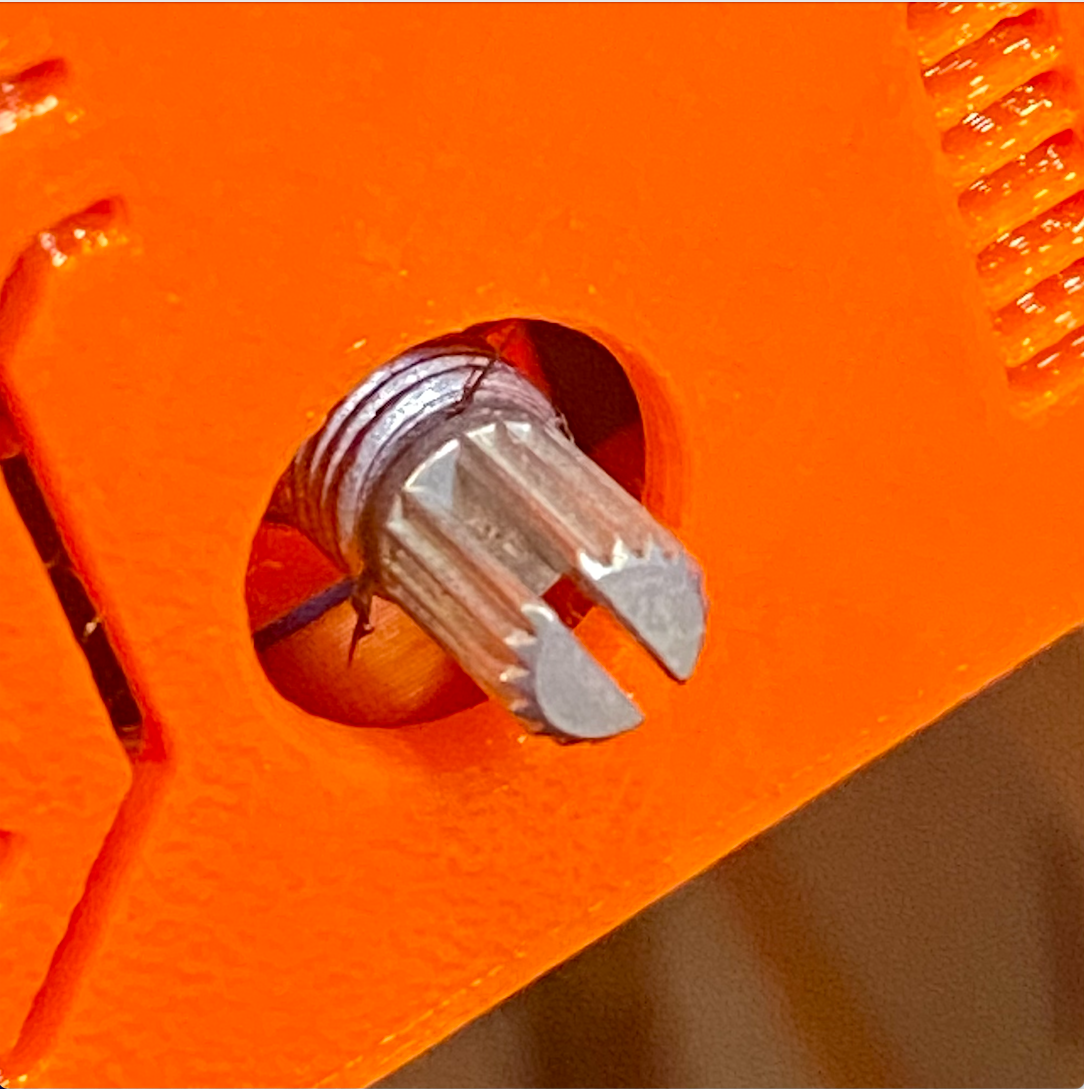

First check the knob. Is there a scrap of filament jammed behind it?

Next check you haven't got a loose connection, including the plugs both the lcd pcb and at the Einsy end...

Remove the knob. Can you click the bare shaft? If so the LCD cover may have worked loose and closed the click-gap, tighten and reassemble carefully.

If the shaft physically clicks but no action results then inspect the PCB tracks, you may have stress-cracked a track, it may be possible to bridge or resolder it or if the damage is too bad you may need a new PCB.

None of these?

The rotary encoder may have worn out. If you are comfortable desoldering then remove and test it, replace with similar, if not then again, a new PCB.

Cheerio,

Is this a new build or a problem with a formerly working printer?

Cheerio,

RE: font control knob will not depress

Formerly working 🙁

RE:

I had this issue early on mine and the knob and the knob was bottoming out. I put a small piece of paper inside the knob so it was a bit higher on the shaft. This fixed my issue. You might try removing the printed know and see how it works bare.

The LCD control knob on my PRUSA printer will not depress (click). It does however rotate. Any ideas?

RE: font control knob will not depress

Must be a fault on the rotary encoder. The rotation function still works but the contacts on the push button are probably worn.

If the printer is still on warranty, Prusa should send you a free new LCD unit, On a expired warranty, you can replace just the rotary encoder or purchase a new LCD from Prusa ( not cheap at all).

Spare encoders are available for next to nothing at Ali-Express and other places. If you're handy with a solder iron, it's perfectly doable, but there's always a fair chance of damaging the PCB of the LCD unit when you desolder the faulty encoder.

First check the knob. Is there a scrap of filament jammed behind it?

Next check you haven't got a loose connection, including the plugs both the lcd pcb and at the Einsy end...

Remove the knob. Can you click the bare shaft? If so the LCD cover may have worked loose and closed the click-gap, tighten and reassemble carefully.

If the shaft physically clicks but no action results then inspect the PCB tracks, you may have stress-cracked a track, it may be possible to bridge or resolder it or if the damage is too bad you may need a new PCB.

None of these?

The rotary encoder may have worn out. If you are comfortable desoldering then remove and test it, replace with similar, if not then again, a new PCB.

Cheerio,

RE: font control knob will not depress

If you end up needing a new part and it isn't covered under warranty, I had success using this on my recent scratch build:

https://www.partsbuilt.com/lcd-screen-b-w-for-prusa-i3-series-ldo/

RE: font control knob will not depress

Well done Diem, and good for you that the knob doesn't needs to be replaced.

It never occurred to me that a brim of filament could find a way in there. How did you manage to achieve that ?..It must be quite difficult to do, even on purpose...😋

RE: font control knob will not depress

Honestly, I have no idea >.<

I just purchased the printer (used), brought it home in the front seat of my car and set it up on my desk. It printed 3 pre loaded prints without any issues and then I ran into an issue with bed adhesion. I'm going to refresh the print bed with acetone and try printing with brims on my next attempt. Additionally, I'm going to setup a light enclosure that should block the AC current that is going through the room without increasing the temperature too much. I'll have to rig up a probe so I can collect some data on air temperature.

Clean with IPA between prints.

At the first hint of a problem, use dishwashing detergent (Dawn/Fairy) and plenty of HOT water, rinse well and dry with a fresh paper towel. Handle by the edges only.

If that's not enough use acetone: once or twice a year at most.

Cheerio,

RE: font control knob will not depress

Good info re: how many times a year to “refresh” vs clean.

I think I had noted that JP in one of the promotional videos for new owners says to “refresh” once per week with acetone and to clean with 90% IPA or windex.

🙂

RE: font control knob will not depress

there are many options....

i usually use

windex is often used to reduce adhesion when printing PETG.

Acetone damaged one of my smooth build plates, and IPA can be hit and miss...

Finger prints and body grease can reduce adhesion.... handle the build plate by the edges, and you have less cleaning to do!

Find a process that works for you.... and happy printing!

Regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

The sheet must be clean. Once it is clean you may need adhesion modifiers depending on which filament is printing.

The commonest contaminant in a domestic setting is fingerprint grease which, especially if children are around, may contain sugars.

IPA and acetone dissolve grease and carry most of it away if wiped off. They don't dissolve sugar.

Detergent and hot water dissolve both.

Think about your working environment - what might be contaminating your printer and what cleans that?

We are assuming the contaminents are human fingerprints, filament residue and PEI oxidants.

But if you are using aerosols in the same room, or spraying paint, laying fibreglass, arc welding ... anything that creates dust, smoke, spray... You get the idea. The bed needs to be clean.

Cheerio,

RE: font control knob will not depress

You just saved me a lot of time and $$$. Was printing with a stringy filament when the control button stopped working. I’d had the knob off a few times trying to troubleshoot but it wasn’t until I saw your picture with the filament caught in behind that I took a much closer look and there it was just barely visible. Phew!!

RE: font control knob will not depress

Thank you for this thread. I just had the same thing happen and it was a small piece of filament wrapped around the dial shaft.