Firmware for upgraded MK3S?

Hey y'all,

I just picked up a pair of used Prusa MK3S. One has the MMU2S, whereas the other one has an upgraded frame. The seller tells me both have upgraded steppers (0.9degree) and ball screws (2.5mm single start?).

Both have a BondTech extruder and perhaps other upgrades. The one with the MMU had firmware 3.8.1 and was being ... finicky ... so I figured I'd update the firmware - to stock Prusa 3.12.2. This didn't work so good, now the printer beeps at me hard on reset and complains that the bed temp (I think) is below minimum.

I'm a total n00b at this, but I'm gathering that the firmware is specific to at least the bed thermistor and perhaps other details. How do I identify the parts and find or build the right firmware?

Siggi

RE: Firmware for upgraded MK3S?

It these printers have a Bondtech extruder installed, in all logic they should have a firmware tuned for Prusa MK3S. Bondtech sell upgrade kits for Prusa and other brands and they release their modified version shortly after the manufacturer upgrades the firmware.

First you must know the exact model of extruder (BMG, LGX ? ), Then you could go to Bondtech web and download the correct version of firmware for that extruder and printer, For instance :

https://www.bondtech.se/knowledge-base/firmware-updates-for-prusa-i3/

Now, if those Mk3S have other modifications (i.e. non standard thermistors) that’s a different story, because you’d need to modify the firmware by yourself.

RE: Firmware for upgraded MK3S?

I have to verify with the previous owner, but I believe the firmware that was on there came from this GitHub branch. Seems the most recent merge of those changes to the Prusa mainline exist here for 3.11.0. As for the hardware, looks like there's an upgraded hotend, 0.9 degree steppers on at least X/Y and the extruder. There are likely also different bed and hotend thermistors, so I guess I need to figure that out.

This is a bit more of a project than I thought I was getting into :).

RE: Firmware for upgraded MK3S?

If you posted pictures we could help

Please help me out by downloading a model it's free and easy but really helps me out https://www.printables.com/@Hello_474427/models

RE: Firmware for upgraded MK3S?

If you posted pictures we could help

Heh, that's a great idea. Will try and get some pictures tomorrow - thanks!

RE: Firmware for upgraded MK3S?

I don't seem to be able to upload photos, I always get an error that says "Post-processing of the image failed likely because the server is busy or does not have enough resources. Uploading a smaller image may help. Suggested maximum size is 2500 pixels.". This is even after downscaling my images to 10% original size.

RE: Firmware for upgraded MK3S?

Hmmm, I see my previous message is "Awaiting moderation". Maybe I can't upload images because I'm in new user moderation jail?

RE: Firmware for upgraded MK3S?

Hi,

I don't know why you are having difficulties posting pictures,

there is no restriction on new users posting pictures during the moderation period.

what I do (In Windows 10, or Windows11) is to start writing a response, then when I am ready to insert a picture, I put the mouse pointer where you would like the picture to appear, and then I Open file manager in a reduced size window so that I can Drag and drop the picture into the bottom of the text entry window. when I get the picture into an acceptable location, the screen turns Blue

and I drop the file.

regards Joan

p.s. you should be out of moderation, your last post tripped the requirements

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: Firmware for upgraded MK3S?

Try put theme into a zip file the upload it

Please help me out by downloading a model it's free and easy but really helps me out https://www.printables.com/@Hello_474427/models

RE:

If you posted pictures we could help

Heh, that's a great idea. Will try and get some pictures tomorrow - thanks!

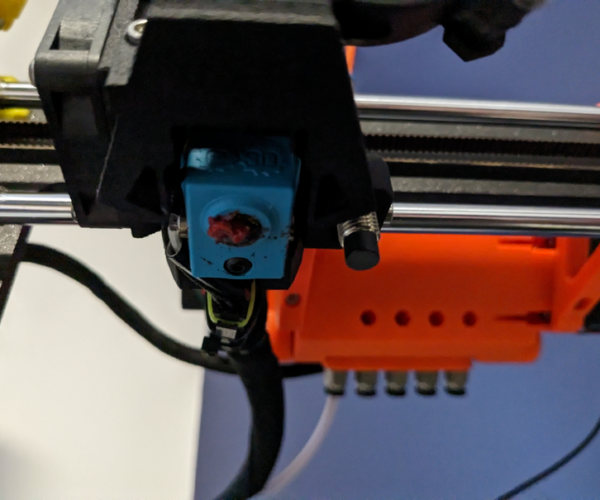

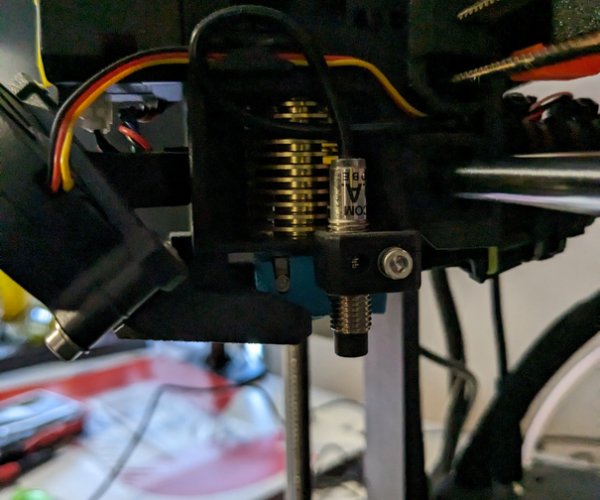

Here are some pics of the extruder and the hotend:

I've managed to build a version of the f3.11 irmware that doesn't scream at me when I power the printer, but I'm currently struggling with the axis limits. Seems there's interference between the extruder wire loom and the frame at 248.75mm, so I'm tempted to reduce the axis limits to get past that to see where I'm at with e.g. the extruder steps.

RE: Firmware for upgraded MK3S?

Hi,

I don't know why you are having difficulties posting pictures,

there is no restriction on new users posting pictures during the moderation period.p.s. you should be out of moderation, your last post tripped the requirements

Weirdness - there was apparently something in the metadata of the pictures that broke the upload. I'm on Linux and I'm using imagemagick to scale the pics - by adding "convert -strip" I was able to upload the pics.

RE: Firmware for upgraded MK3S?

Glad you sorted it, I am out of my depth with Linux!

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: Firmware for upgraded MK3S?

It would appear that you need one of these:

https://www.bondtech.se/knowledge-base/firmware-updates-for-prusa-i3/

RE: Firmware for upgraded MK3S?

It would appear that you need one of these:

https://www.bondtech.se/knowledge-base/firmware-updates-for-prusa-i3/

Because of the 0.9 degree steppers, I built my own custom firmware from this git repo. Apparently it has different motor driver tuning and perhaps other tweaks that I don't understand.

I'm still struggling with the bed calibration, though.

RE: Firmware for upgraded MK3S?

I think this is why I'm having trouble with XYZ axis calibration. There's interference between the ball screw support and extruder and/or fan, which shifts the X-axis homing position some 5mm to the right. This in turn means the calibration routine is searching for the calibration spots in the wrong locations.

I take there's something amiss here?

RE: Firmware for upgraded MK3S?

I think this is why I'm having trouble with XYZ axis calibration. There's interference between the ball screw support and extruder and/or fan, which shifts the X-axis homing position some 5mm to the right. This in turn means the calibration routine is searching for the calibration spots in the wrong locations.

I take there's something amiss here?

So the X-axis parts look very much like the Bear labs X-axis. Maybe I can just file down the ledge that's interfering?

RE: Firmware for upgraded MK3S?

So the X-axis parts look very much like the Bear labs X-axis. Maybe I can just file down the ledge that's interfering?

So, I think this printer may have originally had leadscrews, and the ballscrews that are fitted seem to be larger than at least current production i3 MK3S+. Do they not come with ball screws, rather than lead screws these days? I couldn't find a conclusive answer in the prusa sales literature?

In any case, the ball nuts are fairly long/tall, and I suspect the extruder housing and/or the fan would foul on it if I were to file down that ledge. So I changed the firmware again, and by moving the sense points 5mm to the left, the printer now clears the XYZ axis calibration.

I wonder if the same could be achieved with M206 - homing offsets. I rather doubt it, as the printer would then have the X-axis zero value out of travel bounds?

RE: Firmware for upgraded MK3S?

Those do look like the Bear X-ends, but people have also modified the Prusa X-ends to incorporate the features of the Bear Exxa, while still being compatible with the Prusa extruder. Either way you have a Bondtech extruder, which requires its own firmware. Glad to hear you got it to pass calibration.

I am not sure why anybody would want to bother with ball screws in that application; the standard lead screws and delrin nuts work fine. It's not like that is a high wear area, and you'll always have gravity removing any backlash that might be present in the Z axis.

RE:

I am not sure why anybody would want to bother with ball screws in that application; the standard lead screws and delrin nuts work fine. It's not like that is a high wear area, and you'll always have gravity removing any backlash that might be present in the Z axis.

Good call - I took a closer look at the screws and they're not ballscrews. According to the seller, it's a single-start T8, which I understood as "ballscrew" - my n00b mistake. The nuts are however split, with an anti-backlash spring inbetween them.