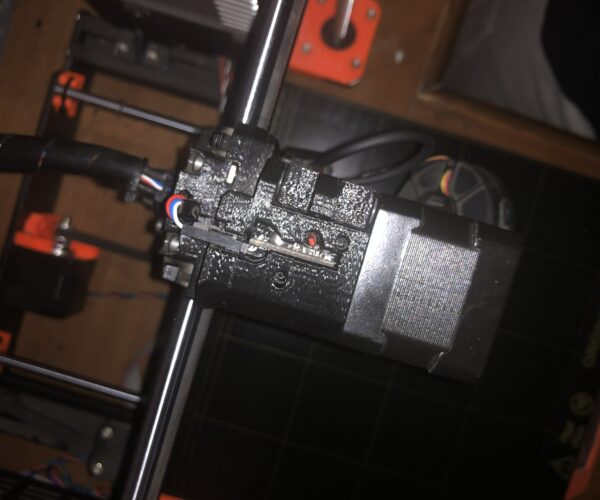

Filament stuck in MK3 extruder body, opposite sensor

As can be seen in the photo, during an unload after a print that began failing due to a lack of extrusion, the filament got stuck after crossing the gears, inside the extruder body. I'm guessing it hadn't cooled enough while leaving the hotend, and solidified while in contact with the printed extruder body. When I tried to pull it out after removing the cap, the filament broke, leaving a very small stick that is difficult to grab. What is the best way to dislodge/remove this piece of filament? I can see drilling it as one option, but I'm hesitant due to the proximity to the filament sensor. Meanwhile, the filament sensor itself is difficult to remove smoothly, and I'm scared of bending the pins or the board itself if I put too much force.

Thanks for any advice

RE: Filament stuck in MK3 extruder body, opposite sensor

I think the best thing is to to push the filament down with eg. a small Allen key. But first disassemble the filament sensor so you don't damage it. Open the door with extruder idler, and you can remove the filement stump there.

Bear MK3 with Bondtech extruder

RE: Filament stuck in MK3 extruder body, opposite sensor

For anyone with the same problem, I managed to fix it by opening it up a bit and removing the sensor, breaking the filament stub all the way down to the hole at the base, and then pushing the blockage out by driving a screw in from the top. I'm pretty sure there are better ways to do it, but I was in a bit of a hurry, and didn't have many tools on hand.