Filament stops flowing, print head carries on

Hi,

I need some help with this Prusa i3 MK3S . At first it worked beautifully but after about 50 hours I cannot get a print to complete, wasted a whole spool of plastic. There is some de-lamination going on, but the big problem plastic stops flowing so printing stops. The print head happily carries but nothing is being printed. De-lamination might be from the plastic flow issue.

I'm using Prusa's suggest Slicer program with default settings and upgraded the firmware. Using PLA, and not cheap stuff. Same thing happens with PLA that came in the printer box, or a spool purchased from Prusa's suggested vendor Vortex.

It seems like the filament is jamming as the stepper grinds away try to advance it, but otoh if I happen to notice it, I can usually unload the filament and it reloads perfectly and squirts a blob out - suggesting nothing was jammed.

I have played with various tension on the feed gear spring, doesn't seem to fix or make or make it worse.

Note this worked perfectly in at first.

In the first photo, the yoke printed perfectly the first time (the one at the back) followed by 6 failures, no change in hardware or software.

Photo 2 - this time the filament broke in unloading. I was able to get a fine pair of snips on it and pull it up (and eventually out). You can see how chewed up it is.

Photo 3 ( apologies for phone camera pic) is of the end of the filament after a jam. The diameter at the end, is slightly larger than the filaments nominal dia. I'm wondering if this is the problem, i.e. if the gears are trying to retract the filament, it jams trying to pull this bulbous part part up, strips the plastic so then it can't subsequently feed down (because its stripped)?

Lastly, video of the sound it makes and showing the gear teeth skipping on the filament

Thoughts? Thanks in advance

RE: Filament stops flowing, print head carries on

Hello! Did you ever sort this as mine is doing the same thing.

RE: Filament stops flowing, print head carries on

Jam comes first. Then filament gets chewed up.

Do some cold pulls and / or cleaning filament.

Then raise your nozzle temperature maybe 10 degrees.

RE: Filament stops flowing, print head carries on

I've been having the same problem, but only since upgrading my i3 MK3 to MK3S. As soon as I hear it clicking, I stop print, do a cold pull and restart. Doesn't happen all the time, but often enough to be frustrating.

RE: Filament stops flowing, print head carries on

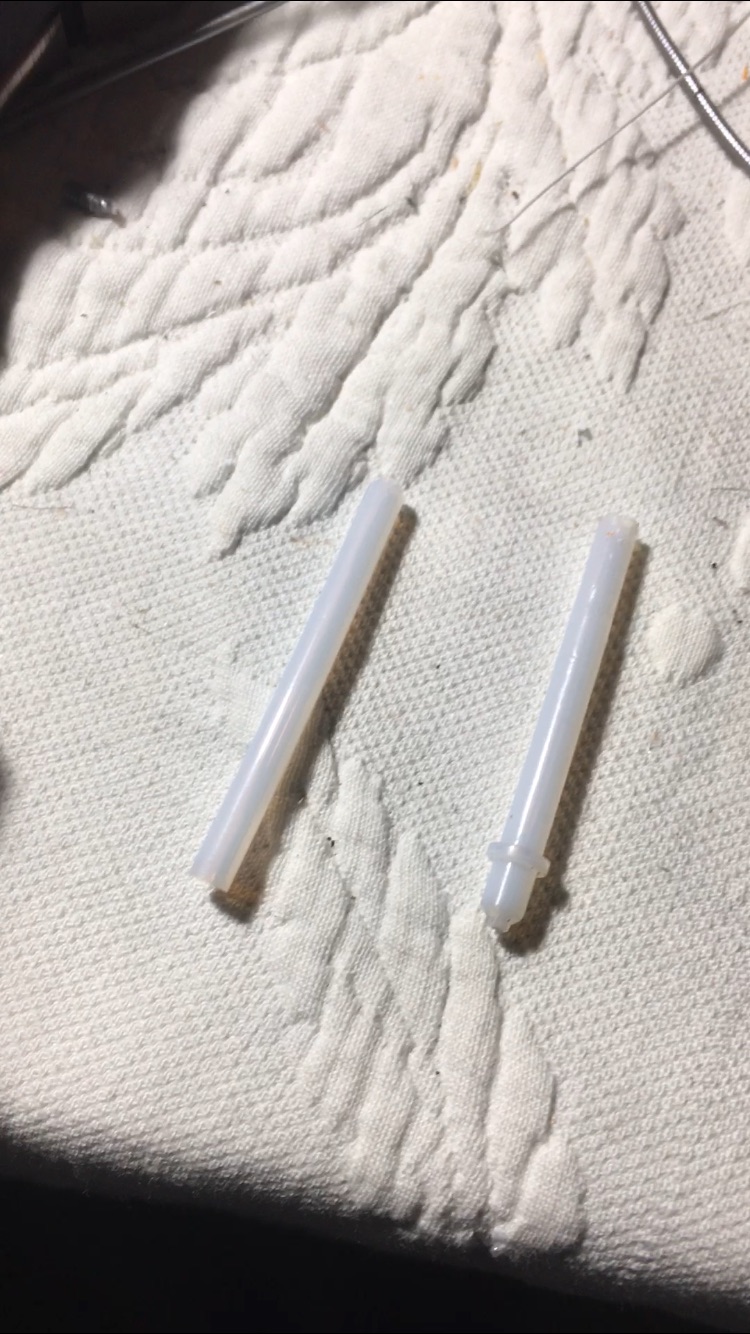

Good morning, I also found the same problem, it is due to a cascade of errors, the temperature setting, which in turn deforms the PTFE tube, inside the lamellar body, which serves to decrease the friction and address the filament, I attach photos

after a series of evaluations, I recommend replacing the PTFE tube, and inserting a steel tube possibly AISI 316 or stainless steel 4mm external x 2mm internal.

I attach the photo that explains the deformation of the PTFE tube, in the photo the tube deformed by the temperture is on the right side.

P.S. : The cleaning of the nozzle should be done by inserting the special tool inside it, but if we were using a ruby nozzle, this procedure could compromise its mechanical integrity, therefore the quickest solution would be to raise the temperature by at least 25 degrees centigrade with respect to the operating temperature, we know that PTFE begins to deteriorate molecularly on the 300 degrees, so if we reached 250 degrees centigrade, we would have a deformation principle, of the aforementioned.

RE: Filament stops flowing, print head carries on

Salve oltre alla soluzione meccanica suddetta nell'antecedente messaggio, che io sto apportando per permettermi di lavorare con altri materiali, più ostici, ho trovato una cosa interessante che mi ha risolto per il 90% del problema e credo che possa risolvere il problema del SIG . MISURETWICE allego il link, controllo del FLOW 👍