Filament Leaking from Heater Block

Hi everyone,

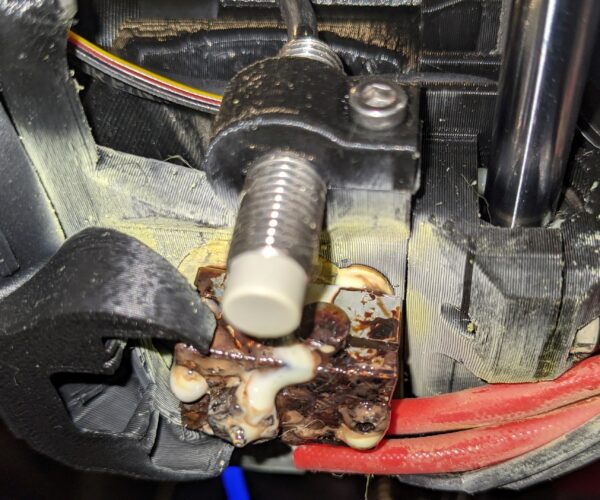

Would anyone be able to assist or provide guidance with fixing leakage from the heater block? I've been using the printer for over a year now but for the past week or so I've noticed more and more blobs from prints. I've stopped using it altogether to prevent any more damage. Would definitely appreciate some help before I go through disassembly and know what to look out for. Thanks.

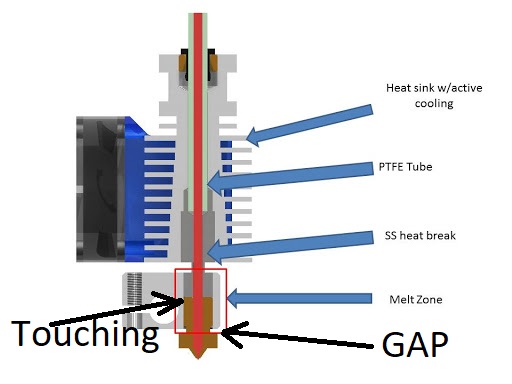

this looks like the nozzle is tight against the heat block and not tight against the heat break, which results in a tiny gap between the nozzle and the heatbreak, where filament can leak. the waste tends to go upwards and out over the hetblock

https://help.prusa3d.com/en/article/changing-or-replacing-the-nozzle_2069

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: Filament Leaking from Heater Block

Sorry to jump in but I'm having the same issue after 6 months of trouble free printing. It doesn't make sense to me that nozzle can be tight against the heat block but have a gap with the heat break and to correct this you wind the nozzle out away from the heat block. Doesn't that increase the gap between the heat break and nozzle also? Does the heat block somehow slide down on the heat break causing the problem?

RE: Filament Leaking from Heater Block

As well as positioning the nozzle correctly you have to screw the heatbreak in to meet it. Once they meet inside the heatblock then when you do your final tightening at 285 degrees the slight gap means you can actually tighten it. If there was no gap left between nozzle and heater BLOCK then it wouldn't be possible to fully tighten nozzle to HEAT BREAK. Of course once you adjust that then you HAVE to redo all your z height calibration again as you will have changed the position of the nozzle. Once its done properly you can change out e3d nozzles and you wont have to change any z height. When I swap mine I usually dont even have to adjust my live z fine tune as they are machined that well.

You can not get a seal between the nozzle and heat block due to the way its machined. You CAN get a seal between the nozzle and heatbreak as the mating surfaces are machined flat to a high tolerance. Well at least they are with e3d original parts. Cheap replacements can vary. If there is any slightest gap then over time plastic seeps into the threads and travels both up and down. You then see melted plastic coming from both top and bottom on the heat block. Make sure both the nozzle and heatbreak mating surfaces are cleaned of all plastic residue when you redo it so you can get that seal.

RE: Filament Leaking from Heater Block

Thanks for the help! I was able to figure out the issue (over tightness in the nozzle). Going through this guide to help replace the damaged parts.