Filament feed stopping

Hi All

I need some help.

I've recently been trying to build a stack of things that I thought would be fairly straightforward. I wish.

To spare you of the whole story, after moving to Cura because it's handling of sorts proved to be more 'sensible' for this particular build, I thought I'd finally got it nailed - I'm trying to build a stack of rings 11 high.

Alas, despite actually getting speeds/supports/temperatures/Z heights I am still bumping into a really frustratingi issue

The issue is, after at least 2hrs of successful printing, is a clicking at the print head - which I know already means it's not being fed through - and if I don't catch it in time then it'll 'air print' until the end of the program.

So, to my question. Why would the filament suddenly decided not to pass through the the nozzle after continuous, successful printing within the same programme/file?

Before you ask..

Prusa MK3S/hardened nozzle/Prusament PLA jet black/build temps: 208/60 degrees.

Many thanks

RE: Filament feed stopping

Hi All

I need some help.

I've recently been trying to build a stack of things that I thought would be fairly straightforward. I wish.

To spare you of the whole story, after moving to Cura because it's handling of sorts proved to be more 'sensible' for this particular build, I thought I'd finally got it nailed - I'm trying to build a stack of rings 11 high.

Alas, despite actually getting speeds/supports/temperatures/Z heights I am still bumping into a really frustratingi issue

The issue is, after at least 2hrs of successful printing, is a clicking at the print head - which I know already means it's not being fed through - and if I don't catch it in time then it'll 'air print' until the end of the program.

So, to my question. Why would the filament suddenly decided not to pass through the the nozzle after continuous, successful printing within the same programme/file?

Before you ask..

Prusa MK3S/hardened nozzle/Prusament PLA jet black/build temps: 208/60 degrees.

Many thanks

hardened steel has a lower thermal conductivity than brass. For this reason, I would increase the nozzle temperature by about 10 to 15 degrees C., otherwise the nozzle tends to clog.

For printing PLA I would recommend a brass nozzle. Alternatively, the nozzle-x or a tungsten carbide would be recommended for printing various carbon-containing materials.

nozzle-x: https://e3d-online.com/products/v6-nozzles

tungsten carbide: https://www.3dmakerengineering.com/products/tungsten-carbide-3d-printer-nozzle?variant=14784857145399

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.

RE: Filament feed stopping

Karl, thank you for the feedback. Regarding the nozzle temperature, I steadily reduced the temperature simply because I had terrible stringing issues. But now I think about it, that when I was using PS and it's support variant (which effectively provided too fragile a structure, so stringing exacerbated the problem. However, I am interested in your comment that collet temps in hardened nozzle can lead to blockages. Additionally, the supports in Cura are far more robust, so while I'm standing here in front of the machine, I'm trying higher temps and it's working, so far!

Thank you also for the links. I will take a look at them.

One detail in curious about. I'm generally getting a matt/satin finish on my bills in the jet black PLA. My first successful build of the current job (a stack of 23 pieces, 209mm tall, 0.2mm layers) came out really well and had a glossy finish.

What is the usual PLA finish to expect? Just wondering if temperatures and nozzle type has an impact?

RE: Filament feed stopping

An update. Good news!

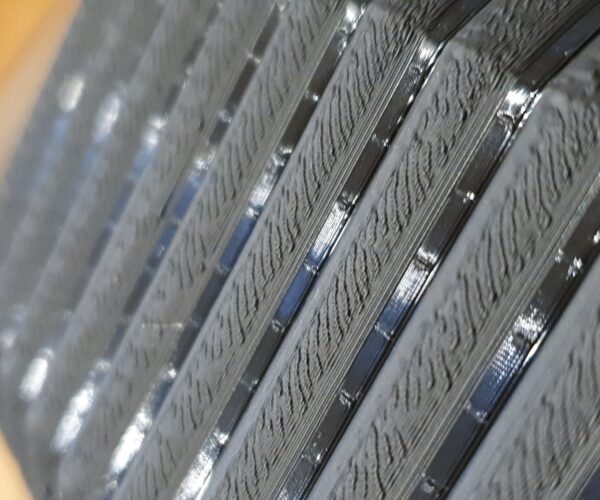

This morning I got up to see the 15hr build had completed successfully! See image.

So, following your advice Karl, I switched back to the brass nozzle (the OEM nozzle that came with the machine). As mentioned, I have raised the temperatures as now the supports are not so fragile, so it is at a constant 215 degrees. Another detail was I made sure the whole printer was better shielded - I have built a Lack enclosure, but the acrylic sheet hasn't arrived due to christmas/covid/late deliveries.

I am unclear if it's down to the nozzle alone, but I now have a slightly more glossy finish (0.2 layers - Prusament PLA).

I have a small issue with the Cura slicer. When it lays the first foundation bead - for the supports - on the inner radius of the rings, it often fails to take and falls off, giving me a stress out that it's going to stick to the head! But despite this fairly consistent bug, it seems to manage. You can see these beads, they look like strings but in fact they are the first beads/support first layer that haven't adhered. Right now, I am wondering if it is possible to increase the feed rate, just for the first layer of the supports? Maybe that is too fine-grained a detail to configure in Cura?

RE: Filament feed stopping

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.

RE: Filament feed stopping

@karl-herbert

I think a temperature tower is going to become a slightly more regular practice for me after this job.

As I moved through multiple builds of these pieces, I discovered another little problem that gave me quite a number of rejects... I am unclear what has actually caused the issue - I tried cleaning the nozzle a couple of times with cold-pulls. I also ran some cleaning filament through it. The only thing I changed was the filament. I ran out of the Prusament (and Prusa are not shipping to the UK right now) so I tried a reel of Amazon basics - which I understood to be fine and maybe this detail has nothing to do with the filament?

Here's a couple of shots of the issue:

Any ideas? I am curious that the support areas built rather nicely!