RE: Filament Curling Around Nozzle - Won't Stick to Bed

Clogged nozzle maybe, does enough filament come out?

Do a few cold pulls, see prusa forum/website how to do a cold pull.

Change the nozzle , is possible the fastest way, to know if nozzle is OK.

Let us see a picture of first layer, and faild prints.

Check the whole printer for loose parts, check belts, etc.

RE: Filament Curling Around Nozzle - Won't Stick to Bed

@bobstro

Haven't tried any of the sample prints but i have tried first layer calibration and it does the same, that should also be raw prusa gcode right?

I have printed with slightly adjusted settings before just fine (also with PETG) , several times it just suddenly started to act up.

When trying to upload a file it kept saying "file not allowed" so here's a google drive link:

https://drive.google.com/file/d/106eBG0hhf6Co2FFubgPmgIKdhiUFWrvZ/view?usp=sharing

RE: Filament Curling Around Nozzle - Won't Stick to Bed

@peter-m-3

Did a couple of cold pulls, looks ok i think? Still having issues though

Video of test print:

https://drive.google.com/file/d/14vhcyrNg5Pp-IPutsT8hvPe4bdlZDE2W/view?usp=sharing

RE:

Yo this just started happening to me, did you ever fix it??? even though its been a whole year

RE: Filament Curling Around Nozzle - Won't Stick to Bed

I recently had the same issue as OP, and tried everything and I mean everything. My Z-level has never been more perfectly set up, the hotend is clean, everything is straight and solid on the extruder mount, the PLA is clean, the heated bed was cleaned as much as I possibly could, and the PINDA is working.

However no matter what I did it would mess up, my first layer would curl and then catch on the extruder which made the entire print pop-off and turn into a giant fused mess. But something -- said early in the posts caught my eye. "Hot water will bead up and sheet off the PEI surface." I noticed that on my more used side the water beaded off slower than on the less used one. My less used beaded super fast. Since I already tried everything, Isopropyl, Acetone, Soap and water I was really confused on how to remove this layer that I thought was limiting my adhesion.

I had this weird cleaner under my sink and decided, might as well try it since nothing else was working. It's called Sol-U-Mel and I diluted it 50% distilled water & 50% sol-u-mel. I rubbed it on the plate and washed it off after a minute and the difference in how fast the water beaded was crazy. I'm excitingly writing this as I am doing my first test print and I will come back with more info after more testing, but this stuff seems to really help with adhesion; it cleans the plate so well. The first print I started after using it stuck first try with no curling at all using the base PrusaSlicer settings for the I3 Mk3.

If you also had the issue of adhesion problems and nothing was working at all, I would recommend this stuff 100% I'll show comparison prints of before and after using the product, as well as what I find in the more tests I'll run in the next few days in another post.

Here's where to buy Sol-U-Mel if you just want to take my word on it (seems to work well so far) https://www.melaleuca.com/productstore/cleaning-and-laundry/sol-u-mel-3-in-1-cleaner292

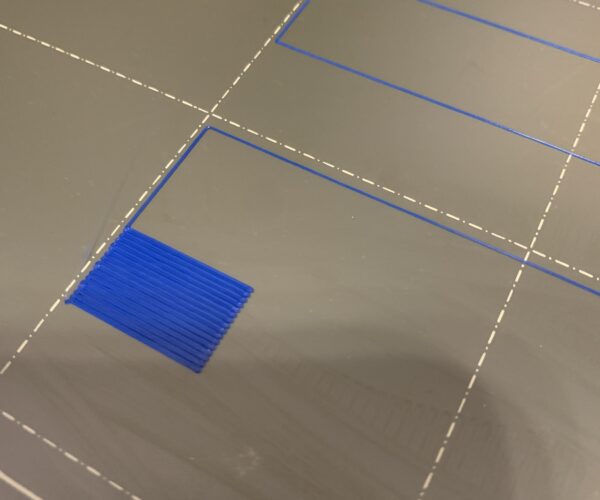

Here is the before and after using Solumel bed adhesion Z-tests-

I'll test further and update with some more information later.