Filament coming out of the extruder

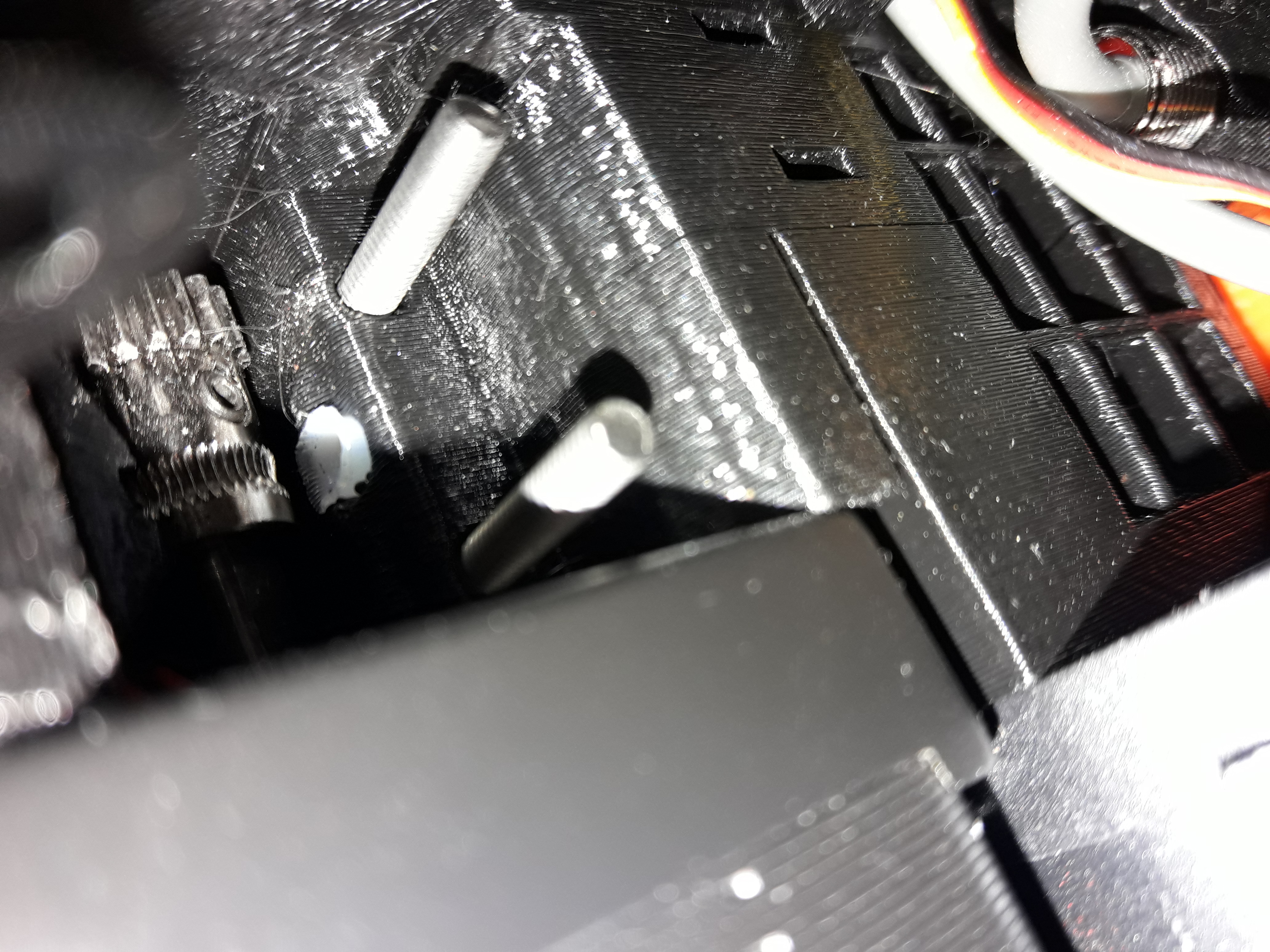

Hi, I´m trying to print NylonX (nylon + carbon fiber), and the filament keeps sliding out of the extruder. I´ve noticed that the white tube under the bowden it´s deformed, cause of the high temperature needed to print those materials.

The filament guide is well aligned, maybe the tube was a little bit displaced down and due to the force and the high temperature it deformed?

I´m printing with 260° hotend, and 100° heatbed. And the printer is inside a box.

I don´t know if the problem is that the tube is deformed or what. Maybe replacing the tube will help?

Thanks for the help!

Re: Filament coming out of the extruder

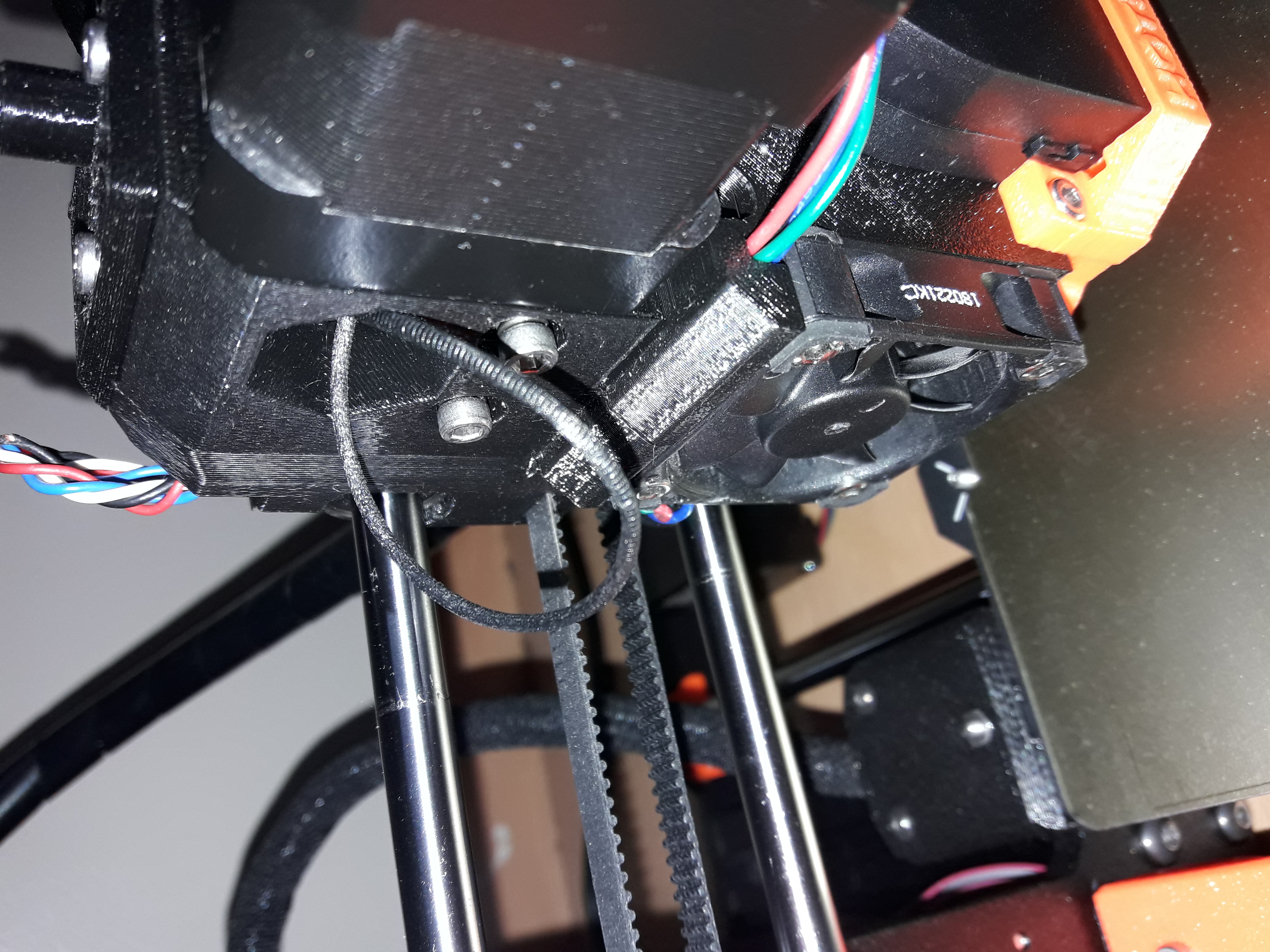

The top of the tube is slightly deformed, but you can test to see if it's a problem or not by manually feeding some filament through the top. If the filament enters the tube cleanly but then stops and starts wrapping around the extruder wheels, you may have a jam. Do NOT try feeding more filament as it will be blocked and wrap around your extruder mechanism.

I've had filament collect lower in the hot end, below that tube, but above the hot zone. You can try pushing down by heating up the nozzle to a printing temperature, then loosening the tensioner as you have in your 2nd picture and pushing some stiff filament, wire or other suitable thin rod from above. With any luck, you'll be able to force the loose material into the hot zone where it will melt and ooze out.

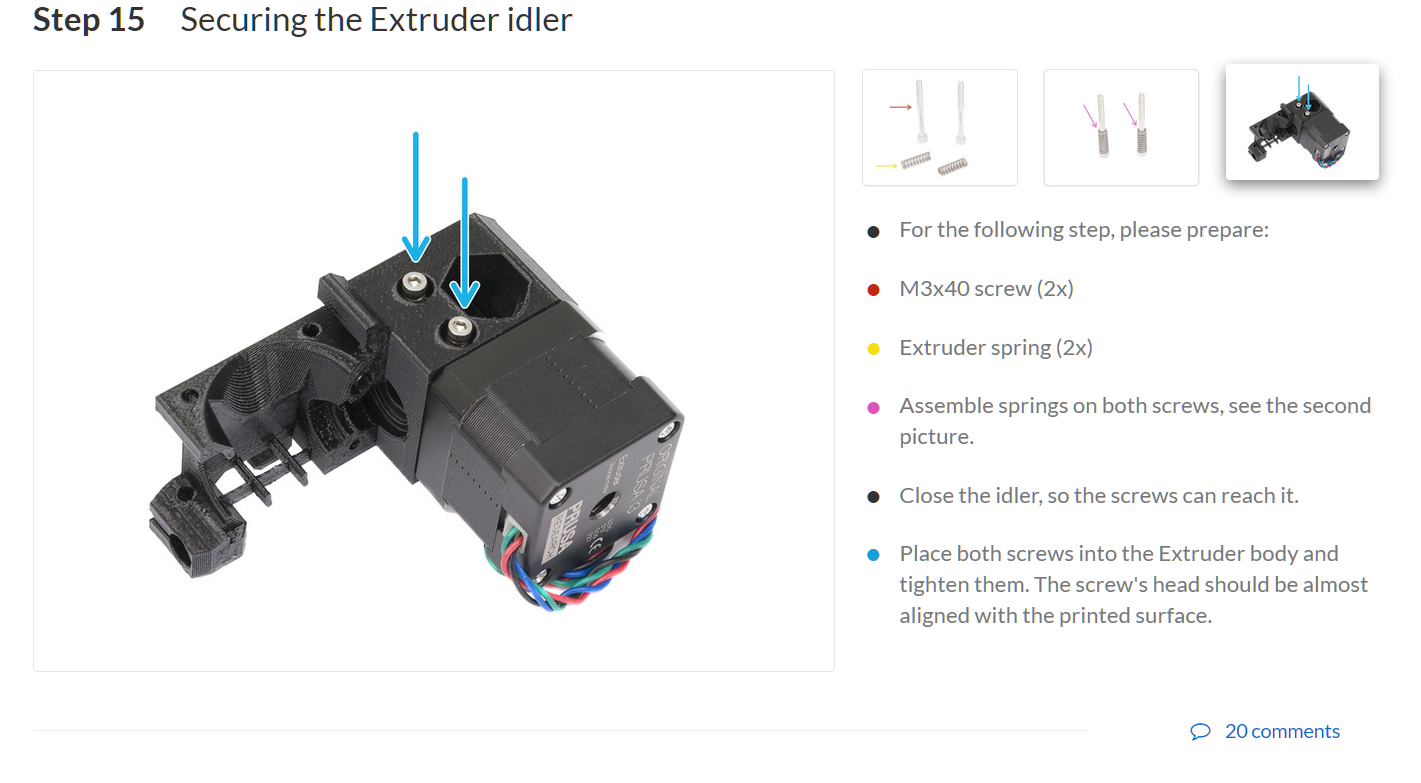

In some cases, I've had to remove the nozzle while hot and push up through the nozzle hole at the bottom of the extruder with a 1.5mm wire. A bit of filament popped up out of the PTFE tube in the extruder that I could then remove. At that point, I could attach the nozzle while still hot, tighten down the extruder tensioner screws as shown in step 15 (mine are nearly flush with the cover) and resume printing normally.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan

Re: Filament coming out of the extruder

I did what you suggested, the filament is oozing very well, didn´t stop or wrap at all. And there is no stuck material inside the hotend.

Now, I realized that the slicer has the retraction enabled. These kind of filament has problems with retraction? I read somewhere that this can bring problems, but i´m not sure. Im going to look if the z offset is too tight and locking the extrusion. But with that z offset , with any other material it´s ok.

Thanks

Re: Filament coming out of the extruder

WARNING: I'm not an expert with nylon or any other material!

I'm not aware of nylon being particularly prone to jamming from retraction. What slicer are you using? I've been working with Slic3r 1.40.0 lately since that seems to be where Prusa is focusing development efforts. I have noticed that the filament profiles for a variety of materials work even with the same print speed settings. The magic seems to be in the Filament Settings->Max volumetric speed setting. This controls the amount of filament pushed through the extruder over time, and will impact all print settings. If I'm understanding correctly, Slic3r will respect this setting, keeping flow low for thicker materials, allowing them to print up to the speeds specified in the print settings, but only so long as the flow rate isn't too high.

I was surprised when I was able to print Colorfabb XT-CF20 well without changing print settings, although it was slow. I noticed the max volumetric speed was set to 1, versus 15 for PLA or 8 for PETG. They don't have a preset for Nylon, but the preset for Taulman Bridge has it set to 10. If nylon is thicker than other materials, it may require slowing down the amount of filament pushed through the extruder. If you push too hard, you'll get jamming and back-pressure in the feed mechanism, which may explain what you're seeing.

If only to test, I'd suggest trying Slic3r 1.40.0 and try adjusting these settings. You might try a max volumetric speed of 1just to see if it works. If so, gradually increase it to see if there's a sweet spot for your filament. If so, please save that filament profile and share it with us!

Good luck with it.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan

Re: Filament coming out of the extruder

Thanks for your support. I will investigate and try to set this values , of course I will share it.

Again, thanks a lot!!!