Extruder Pausing, Overshooting Print, and Causing "Crash detected" Error

I've been having an issue with my Prusa i3 MK3 with the extruder overshooting the print, pausing at seemingly random intervals during the print, and causing "Crash detected" resets.

I first noticed the issue when I checked in on an in-progress print and noticed that the layer that was currently printing was a mess, with lines of filament way outside the expected print bounds, and a "Crash detected" message displayed on the screen. I stopped the print to investigate. After doing some looking into possible causes of the error, I suspected my x-axis belt might be slipping, as it seemed a bit loose to me. I ran a full xyz calibration and a first layer calibration to be sure everything was in order, then performed a self test. However, the self test passed, and the Belt Status values were in the expected range, so I left the belt alone.

I re-sliced the .stl of the model that had failed, and printed it again, this time recording a video of the print in case the error reoccurred. About 1 hour 20 minutes into the print, the extruder paused, overshot the print area, and crashed into the limits of the print bed, causing a "Crash detected" error and causing the printer to attempt to recover. I let the print go a bit longer, and the extruder paused or overshot the print area several more times, eventually causing the stepper motors to "grind" and which point I stopped the print. The failure occurred in about the same spot as the previous failure (nine layers up).

I reformatted my SD card to eliminate data corruption as a possible cause, re-sliced the model, and attempted to print it again. I decided that, since the printer was attempting to recover, I would let it print (barring any worse failures) to see if any additional information could be gleaned from the remainder of the print. The issues occurred again, but appeared to only occur on one layer (again, nine from the bottom), after which the print printed normally, albeit with one layer jutting out.

I modified the model itself, re-rendered and sliced it, and printed it again. This time I observed the issues starting at the same point and continuing for a few layers, with the rest of the print printing smoothly, but shifted to be over the first erroneous layer. I then printed a small test cube with a "floor" at the same point as the problem model, which printed without issue. I made further modifications to the original file, including changing the thickness of the "floor" (this was my best guess for why the issues appear to occur at the same point each time). This time, the issue appeared about 1/3 of the way through the second layer, at which point I stopped the print.

Does anyone have any idea what might be causing this issue, or any steps I can take to troubleshoot it?

Thank you.

RE: Extruder Pausing, Overshooting Print, and Causing "Crash detected" Error

Regular axis crashes are often bearing related, in that increased friction in either 1 or both directions causes a motor current spike which gets detected as a crash. An occasional crash where the part has lifted or curled up on the infill and the nozzle has hit it are down to combinations of model geometry and slicer settings as well as the obvious of bed adhesion for lifting parts.

Shifted layers are an indication of loose belts or loose pulley's.

Bearing friction is nearly always down to the fact that they have been improperly lubricated (ie not lubricated at all during build). This is down to Prusa believing that the packing grease that bearing are shipped with is suitable to run the bearing with. Its not. They can fail within days to a few weeks. As a stopgap measure to check if this is your issue you can use a light machine oil such as 3-in-1 or a sewing machine oil on the rods and work it past the dust seals by moving the axis back and forth then wiping off the excess.

If this temporarily sorts the problem then you have found the issue and at some point soon you should disassemble the axis and fully lubricate the bearings with a proper grease.

RE: Extruder Pausing, Overshooting Print, and Causing "Crash detected" Error

An occasional crash where the part has lifted or curled up on the infill and the nozzle has hit it are down to combinations of model geometry and slicer settings as well as the obvious of bed adhesion for lifting parts.

Doubtfully the case here, as, watching the print, it looks perfectly flat with good adhesion until the errors begin.

Shifted layers are an indication of loose belts or loose pulley's.

I may try tightening the x-axis belt despite the Belt Status values being within range- it is definitely looser than the y-axis belt, and can easily be pinched together with no resistance.

Bearing friction is nearly always down to the fact that they have been improperly lubricated (ie not lubricated at all during build). This is down to Prusa believing that the packing grease that bearing are shipped with is suitable to run the bearing with. Its not. They can fail within days to a few weeks. As a stopgap measure to check if this is your issue you can use a light machine oil such as 3-in-1 or a sewing machine oil on the rods and work it past the dust seals by moving the axis back and forth then wiping off the excess.

If this temporarily sorts the problem then you have found the issue and at some point soon you should disassemble the axis and fully lubricate the bearings with a proper grease.

This may be it, as I haven't fully re-lubricated the axes since I received the printer, though I did try lubricating the rods in much the way you described (adding lube to the rod and running the extruder/plate back and forth over them) with a light duty oil during my troubleshooting above (I believe before the recorded print, but I don't recall exactly).

Can you elaborate on "a proper grease"? I have some Super Lube brand synthetic grease, in addition to the oil mentioned above. Would that be appropriate for this application?

RE: Extruder Pausing, Overshooting Print, and Causing "Crash detected" Error

@faokryn

Super lube should be fine for packing into the bearings once they have been removed. Getting it through the seals while on the rods will be difficult which is where the thin oil comes in. The only way to get the grease in is to physically remove the bearing from the rods which is a pain in the backside but it’s one of those things that needs doing from time to time.

There are a few instances of software issues causing the extruder to go wild but if you have been running fine in the past then bearings are the most common cause. You can check friction by taking the belt off the motor and moving it by hand to get a feel for how silky it moves. Once you have ruled out the basics then you can go on to more less likely stuff. If you do think it’s the model as sliced then you could zip up the gcode you used and attach it and we could give it a go printing if it happens only a few layers up.

RE: Extruder Pausing, Overshooting Print, and Causing "Crash detected" Error

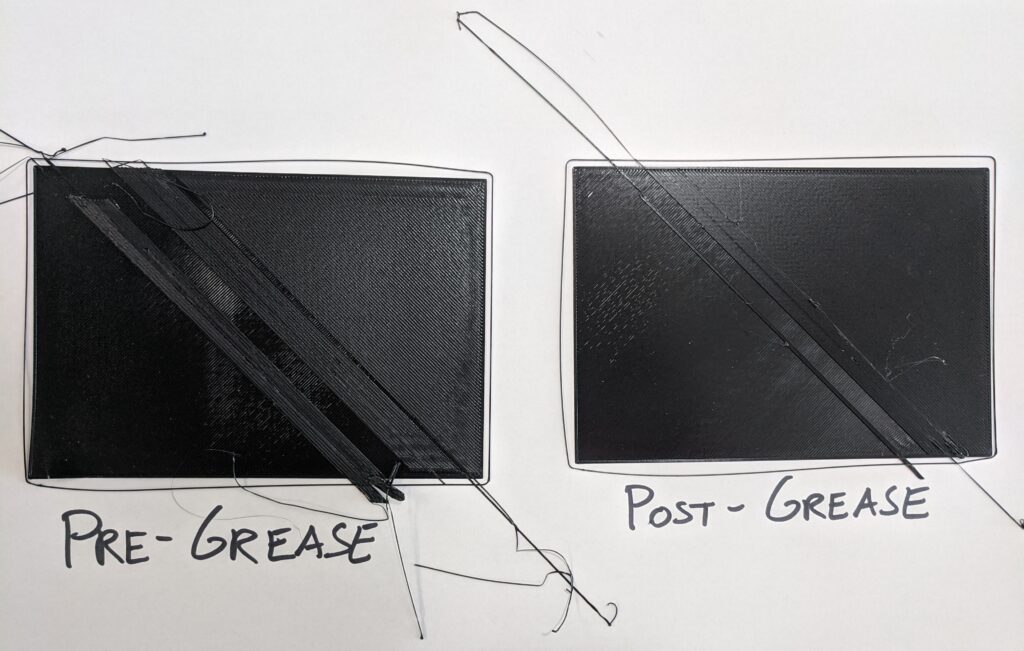

I had a chance to lubricate the bearings, and, unfortunately, it didn't resolve my issue. I applied the Super Lube grease using an applicator I printed (without issue) before removing the bearings. I then reassembled everything, and ran through the full calibration wizard to do self-test, xyz calibration, and first layer calibration. After that, I printed the test cube I mentioned in my first post, which printed without issue. Feeling optimistic, I printed the latest version of the model that has been giving me trouble. The same behavior occurred: the print started out fine, then the print head suddenly stopped briefly before overshooting the print area, a few moments after which I stopped the print. The error appears to have occurred approximately (but not exactly) at the same point as the pre-grease print:

I am now running a different, longer (13+ hours) print to see if other long prints will fail, since I've had success printing smaller, shorter prints while this issue has been occurring. At this point the print has been going smoothly for a couple of hours. I will report back any change.

It's starting to feel like an issue with the model, given the consistency of where the issue occurs, and the fact that I've so far only seen the issue occur on versions of this model. That seems odd to me though, since, as I mentioned, I've modified, re-rendered, and re-sliced the model several times, and experienced some version of this issue each time. If anyone would be willing to take a look at the gcode or try printing it themselves, I posted up the gcode here. This is the version that was printed for the pre-grease/post-grease comparison photo above, and failed for me both times about half of the way through the second layer. It was sliced for a Prusa i3 Mk3 with a 0.4 mm extruder nozzle and PLA filament.