eSUN PETG INI for Slic3r on MK3 ?

Hello to all,

I'm working a lot on eSUN to have decent results, but still not happy.

Could someone share their INI file for eSUN PETG filament?

Thanks,

Simon

Re: eSUN PETG INI for Slic3r on MK3 ?

I have the same question in another forum - no answers yet. Did you figure anything out?

Re: eSUN PETG INI for Slic3r on MK3 ?

What kinds of problems are you having? I've printed a lot with this filament on the MK2S. Not perfectly all the time, but mostly pretty well.

I have an MK3 I'm building, so I'm definitely interested in problems (and solutions)

Re: eSUN PETG INI for Slic3r on MK3 ?

I’ve ran through most of a spool of E-Sun Orange PETG and it prints awesome at default Prusa PET profile for me. As the last person asked, what kind of problems are you seeing?

Re: eSUN PETG INI for Slic3r on MK3 ?

i had tons of problems early on with esun petg on my mk3 using cura but since switching to slic3r PE none. I even printed a couple of things with 200mm/s infill and they turned out perfectly.

only thing i have done is turn the cooling down from 30-50 to 20-40 and 0.3 elephant foot correction

Re: eSUN PETG INI for Slic3r on MK3 ?

i had tons of problems early on with esun petg on my mk3 using cura but since switching to slic3r PE none. I even printed a couple of things with 200mm/s infill and they turned out perfectly.

only thing i have done is turn the cooling down from 30-50 to 20-40 and 0.3 elephant foot correction

Hello,

Well, my experiences are started with PLA which has worked every time very well.

Now on MK3 the speed is amazing and all it's ok!

I've decided to start using PETG and at the beginning Simplify3D. Now I'm back to Slic3r and seems works better.

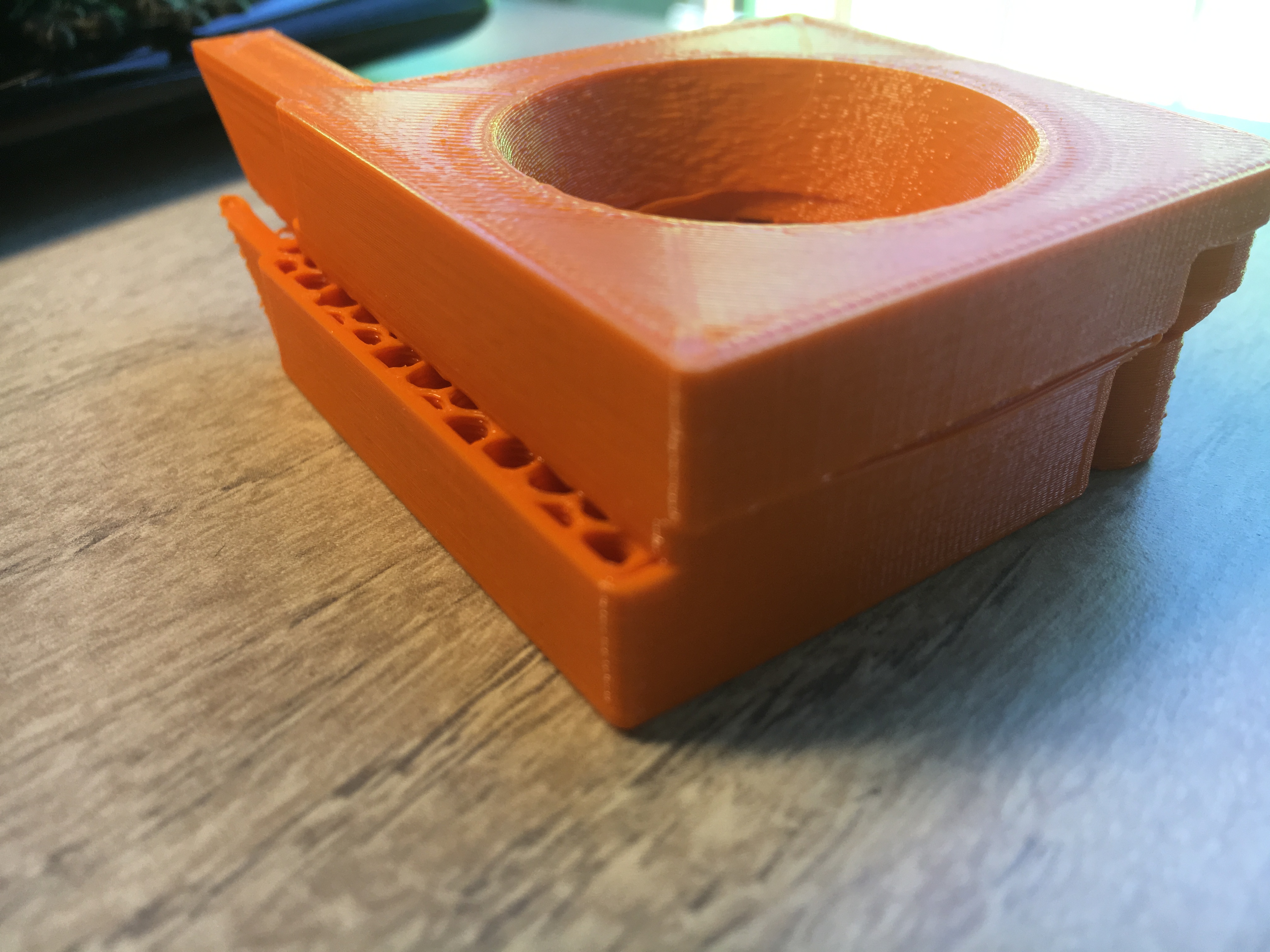

The main problems are related to blobbing like this (taken from Simplify3d):

Not so much like above, but still a little.

Now I've increased the Z-Layer Tune. Actually I'm using PLA with -0.650 and PETG -0.550, like descvibed here:

Source:

https://rigid.ink/blogs/news/175700615-petg-filament-heres-what-you-need-to-know

This material doesn’t need to be squeezed onto your heated bed, you want to leave a slightly larger gap on the Z axis to allow more room for the plastic to lay down

Another big change I've applied is decreasing a lot the speed only for the first layer to 15-20mm/s

I was asking if there are other changes I could apply to better results.

@cris I'll try your fan settings. The fan is disabled in my case for the first 3 layers as well." =

But what setting is this "0.3 elephant foot correction" ?

Thanks,

Simon

Re: eSUN PETG INI for Slic3r on MK3 ?

The main problems are related to blobbing like this (taken from Simplify3d):

Another big change I've applied is decreasing a lot the speed only for the first layer to 15-20mm/s

I was asking if there are other changes I could apply to better results.

@cris I'll try your fan settings. The fan is disabled in my case for the first 3 layers as well." =

But what setting is this "0.3 elephant foot correction" ?

Thanks,

Simon

Elephant - print settings - advanced - other what it does is shrink the first layer a bit to compensate for how the bottom squishes from being in contact with the heat bed

other changes i would suggest is turning down infill to 60mm/s give the filament a second or so longer to set.

blobbing most often occurs when you are going to fast and the last layer of the petg does not have time to cool down so you pick it right back up brushing the nozzle by it and then drop off a blob every now and then

Simplify3d is nice but honestly Prusa has tuned their fork of slic3r heavily. It and prusa control are all i use now and prior to now i have always used cura.

Esun Pet-g settings

This is a good page stickied by the reseller for USA intservo. However, xyzfabs.com is down now so wait for it to come back up and look at this page The link below is available and covers almost everything with esun pet-g

https://www.xyzfabs.com/forums/topic/63/print-settings-for-petg-esun-solid-black-filament

Re: eSUN PETG INI for Slic3r on MK3 ?

Elephant - print settings - advanced - other what it does is shrink the first layer a bit to compensate for how the bottom squishes from being in contact with the heat bed

other changes i would suggest is turning down infill to 60mm/s give the filament a second or so longer to set.

blobbing most often occurs when you are going to fast and the last layer of the petg does not have time to cool down so you pick it right back up brushing the nozzle by it and then drop off a blob every now and then

Simplify3d is nice but honestly Prusa has tuned their fork of slic3r heavily. It and prusa control are all i use now and prior to now i have always used cura.

Esun Pet-g settings

This is a good page stickied by the reseller for USA intservo. However, xyzfabs.com is down now so wait for it to come back up and look at this page The link below is available and covers almost everything with esun pet-g

https://www.xyzfabs.com/forums/topic/63/print-settings-for-petg-esun-solid-black-filament

Thanks,

I'll test your suggestions as well the ones on the link you've shared.

Bye!

Simon

Re: eSUN PETG INI for Slic3r on MK3 ?

Hello,

Long time ago, but have again a question with eSun.

Now it prints mostly ok, expect in a situation. Hope to explain it correctly.

The first layers are print mostly well. After the first layers, in case of a cube, it starts printing the infill. A the end of the infill it prints the externa shell, a 100% flat surface. At this point it blobs a little. Seems like during the shell layer some parts are scratched from the nozzle and then, as soon a blob is formed, it could detach and fall on the surface. Could it be an issue related to extruder multiplier or temperature? Or what else?

The perimeter is ok.

Thanks,

Simon

Re: eSUN PETG INI for Slic3r on MK3 ?

I’ve ran through most of a spool of E-Sun Orange PETG and it prints awesome at default Prusa PET profile for me. As the last person asked, what kind of problems are you seeing?

Sorry to hijack the thread, but what's that Esun Orange like? Is it solid or more transparent? I've got many of the solid PETG (white, red, green, gold) but hesitated with the orange as it looked rather translucent.

Cheers

Re: eSUN PETG INI for Slic3r on MK3 ?

Hello,

At this point it blobs a little. Seems like during the shell layer some parts are scratched from the nozzle and then, as soon a blob is formed, it could detach and fall on the surface. Could it be an issue related to extruder multiplier or temperature? Or what else?

The perimeter is ok.

Thanks,

Simon

What are your retraction settings? Do you get any stringing with your current settings?

Re: eSUN PETG INI for Slic3r on MK3 ?

Here:

retract_before_travel = 1

retract_before_wipe = 0%

retract_layer_change = 1

retract_length = 1.2

retract_length_toolchange = 3

retract_lift = 0.6

retract_lift_above = 0

retract_lift_below = 199

retract_restart_extra = 0

retract_restart_extra_toolchange = 0

retract_speed = 50

What do you thing?

I've tried to reduce the speed (70mm/s) for infill and solid infill. Seems a little better.

Yesterday I've looked a print and confirm seems really generated during the infill creation (it was honeycomb). The first layer above the infill is "collecting" some little spikes that are causing then blobs.

Simon

Re: eSUN PETG INI for Slic3r on MK3 ?

Try:

Retract Length = 0.4

Lift Z = 0

Retract Speed = 35

Re: eSUN PETG INI for Slic3r on MK3 ?

Try:

Retract Length = 0.4

Lift Z = 0

Retract Speed = 35

Thanks! I'll try it!!

Could you share your ini?

I've also edited those settings compared to the original Prusa ones:

PRINTER:

Filament extruder multiplier: 1.02

Temperatures 250 - 245

Bed: 85 - 85

FILAMENT:

Fan Speed Min 100 Max 100

Bridges Fan Speed: 100

Disable fan first 2 layers

Cooling Thresholds: 20secs -10secs -10mm/s

PRINT:

Fill Pattern: Honeycomb

Speed Infill: 110 - now reduced to 70

Speed Solid Infill: 110 - now reduced to 70

First Layer Speed: 20

Elephant foot compensation: 0.3

Thanks!

Simon

Re: eSUN PETG INI for Slic3r on MK3 ?

Hi again,

I've tested with these settings, taken from gcode and based on rob.l6 suggestions:

; avoid_crossing_perimeters = 0

; bed_shape = 0x0,250x0,250x210,0x210

; bed_temperature = 85

; before_layer_gcode = ;BEFORE_LAYER_CHANGE\n;[layer_z]\n\n

; between_objects_gcode =

; bridge_acceleration = 1000

; bridge_fan_speed = 100

; brim_width = 0

; complete_objects = 0

; cooling = 1

; default_acceleration = 1000

; deretract_speed = 0

; disable_fan_first_layers = 2

; duplicate_distance = 6

; end_filament_gcode = "; Filament-specific end gcode"

; end_gcode = G4 ; wait\nM221 S100\nM104 S0 ; turn off temperature\nM140 S0 ; turn off heatbed\nM107 ; turn off fan\nG1 X0 Y200; home X axis\nM84 ; disable motors

; extruder_clearance_height = 20

; extruder_clearance_radius = 20

; extruder_colour = #FFFF00

; extruder_offset = 0x0

; extrusion_axis = E

; extrusion_multiplier = 1.02

; fan_always_on = 0

; fan_below_layer_time = 20

; filament_colour = #FF8000

; filament_cost = 0

; filament_density = 1.25

; filament_diameter = 1.75

; filament_max_volumetric_speed = 0

; filament_notes = "List of manufacturers tested with standart PET print settings for MK2:\n\nE3D Edge\nFillamentum CPE GH100\nPlasty Mladeč PETG"

; filament_soluble = 0

; filament_type = PET

; first_layer_acceleration = 1000

; first_layer_bed_temperature = 85

; first_layer_extrusion_width = 0.42

; first_layer_speed = 40%

; first_layer_temperature = 250

; gcode_comments = 0

; gcode_flavor = marlin

; infill_acceleration = 1500

; infill_first = 0

; layer_gcode = ;AFTER_LAYER_CHANGE\n;[layer_z]

; max_fan_speed = 100

; max_layer_height = 0.25

; max_print_speed = 200

; max_volumetric_extrusion_rate_slope_negative = 0

; max_volumetric_extrusion_rate_slope_positive = 0

; max_volumetric_speed = 0

; min_fan_speed = 100

; min_layer_height = 0.07

; min_print_speed = 10

; min_skirt_length = 4

; notes =

; nozzle_diameter = 0.4

; only_retract_when_crossing_perimeters = 0

; ooze_prevention = 0

; output_filename_format = [input_filename_base].gcode

; perimeter_acceleration = 800

; post_process =

; printer_notes = Don't remove the following keywords! These keywords are used in the "compatible printer" condition of the print and filament profiles to link the particular print and filament profiles to this printer profile.\nPRINTER_VENDOR_PRUSA3D\nPRINTER_MODEL_MK3\n

; resolution = 0

; retract_before_travel = 1

; retract_before_wipe = 0%

; retract_layer_change = 1

; retract_length = 0.4

; retract_length_toolchange = 3

; retract_lift = 0

; retract_lift_above = 0

; retract_lift_below = 199

; retract_restart_extra = 0

; retract_restart_extra_toolchange = 0

; retract_speed = 35

; single_extruder_multi_material = 0

; skirt_distance = 2

; skirt_height = 3

; skirts = 1

; slowdown_below_layer_time = 10

; spiral_vase = 0

; standby_temperature_delta = -5

; start_filament_gcode = "M900 K{if printer_notes=~/.*PRINTER_HAS_BOWDEN.*/}200{else}45{endif}; Filament gcode"

; start_gcode = M115 U3.1.1-RC5 ; tell printer latest fw version\nM201 X1000 Y1000 Z200 E5000 ; sets maximum accelerations, mm/sec^2\nM203 X200 Y200 Z12 E120 ; sets maximum feedrates, mm/sec\nM204 S1250 T1250 ; sets acceleration (S) and retract acceleration (T)\nM205 X10 Y10 Z0.4 E2.5 ; sets the jerk limits, mm/sec\nM205 S0 T0 ; sets the minimum extruding and travel feed rate, mm/sec\nM83 ; extruder relative mode\nM104 S[first_layer_temperature] ; set extruder temp\nM140 S[first_layer_bed_temperature] ; set bed temp\nM190 S[first_layer_bed_temperature] ; wait for bed temp\nM109 S[first_layer_temperature] ; wait for extruder temp\nG28 W ; home all without mesh bed level\nG80 ; mesh bed leveling\nG1 Y-3.0 F1000.0 ; go outside print area\nG92 E0.0\nG1 X60.0 E9.0 F1000.0 ; intro line\nG1 X100.0 E12.5 F1000.0 ; intro line\nG92 E0.0\nM221 S{if layer_height<0.075}100{else}95{endif}

; temperature = 245

; threads = 4

; toolchange_gcode =

; travel_speed = 250

; use_firmware_retraction = 0

; use_relative_e_distances = 1

; use_volumetric_e = 0

; variable_layer_height = 1

; wipe = 1

; wipe_tower = 1

; wipe_tower_per_color_wipe = 15

; wipe_tower_width = 60

; wipe_tower_x = 180

; wipe_tower_y = 140

; z_offset = 0

; clip_multipart_objects = 1

; dont_support_bridges = 1

; elefant_foot_compensation = 0.3

; extrusion_width = 0.45

; first_layer_height = 0.2

; infill_only_where_needed = 0

; interface_shells = 0

; layer_height = 0.2

; raft_layers = 0

; seam_position = nearest

; support_material = 0

; support_material_angle = 0

; support_material_buildplate_only = 0

; support_material_contact_distance = 0.15

; support_material_enforce_layers = 0

; support_material_extruder = 0

; support_material_extrusion_width = 0.35

; support_material_interface_contact_loops = 0

; support_material_interface_extruder = 0

; support_material_interface_layers = 2

; support_material_interface_spacing = 0.2

; support_material_interface_speed = 100%

; support_material_pattern = rectilinear

; support_material_spacing = 2

; support_material_speed = 50

; support_material_synchronize_layers = 0

; support_material_threshold = 45

; support_material_with_sheath = 0

; support_material_xy_spacing = 60%

; xy_size_compensation = 0

; bottom_solid_layers = 4

; bridge_angle = 0

; bridge_flow_ratio = 0.8

; bridge_speed = 30

; ensure_vertical_shell_thickness = 1

; external_fill_pattern = rectilinear

; external_perimeter_extrusion_width = 0.45

; external_perimeter_speed = 35

; external_perimeters_first = 0

; extra_perimeters = 0

; fill_angle = 45

; fill_density = 20%

; fill_pattern = honeycomb

; gap_fill_speed = 40

; infill_every_layers = 1

; infill_extruder = 1

; infill_extrusion_width = 0.45

; infill_overlap = 25%

; infill_speed = 70

; overhangs = 0

; perimeter_extruder = 1

; perimeter_extrusion_width = 0.45

; perimeter_speed = 45

; perimeters = 2

; small_perimeter_speed = 20

; solid_infill_below_area = 0

; solid_infill_every_layers = 0

; solid_infill_extruder = 1

; solid_infill_extrusion_width = 0.45

; solid_infill_speed = 70

; thin_walls = 0

; top_infill_extrusion_width = 0.4

; top_solid_infill_speed = 50

; top_solid_layers = 5

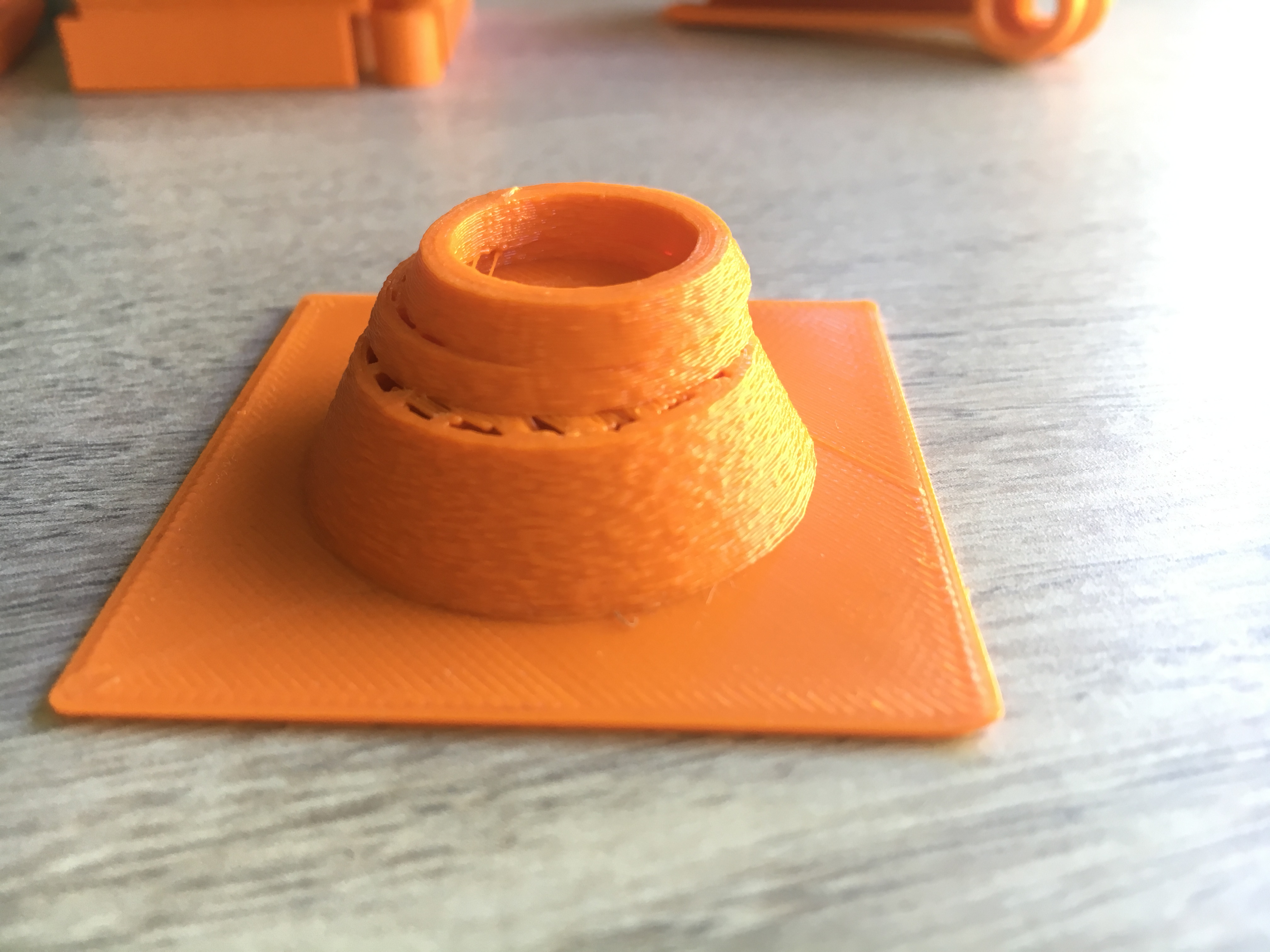

The result is terrible.

Attention, this is not a eSun, but Real Filaments. Ok, I know it's another type, but always PETG.

BTW, really strange the results.

I've one BIG issue and one minor issue.

BIG: there was a SHIFT in the print, and a -one-night-long- print is gone 🙁

The second issue is on the curves. As you can see, the straight part is more or less ok, the curves are rough

I've noticed that during the printing, some parts at the corners were a little high, like curly. I suspect, having z-hop to zero, the extruder could have hit some parts and the shift was caused.

Now it's printing again with those modifications, compared to the above print:

< = OLD PRINT WITH ABOVE RESULTS

> = NEW PRINT, IN PROGRESS RIGHT NOW

36c36

< ; first_layer_speed = 40%

---

> ; first_layer_speed = 20

65c65

< ; retract_length = 0.4

---

> ; retract_length = 1

67c67

< ; retract_lift = 0

---

> ; retract_lift = 0.5

138,139c138,139

< ; fill_density = 20%

< ; fill_pattern = honeycomb

---

> ; fill_density = 15%

> ; fill_pattern = grid

145c145

< ; infill_speed = 70

---

> ; infill_speed = 60

156c156

< ; solid_infill_speed = 70

---

> ; solid_infill_speed = 60

Ideas or suggestions?

Thanks all,

Simon

Re: eSUN PETG INI for Slic3r on MK3 ?

Yeah, you're right, that's pretty bad. Are you running the latest firmware?

Anyhow below is the whole Slic3r config file that I run for ESun PETG ...

I would try "testing" these settings first say on some ESun PETG printing calibration squares, then small calibration cubes etc just to see the outcome, rather than trying some big model.

Also, one caveat on these settings. I pulled them from a MK2s not Mk3, so you may wish to set the printer in Slic3r back to Mk3.

# generated by Slic3r Prusa Edition 1.39.2+win64 on 2018-05-22 at 15:01:38

avoid_crossing_perimeters = 0

bed_shape = 0x0,250x0,250x210,0x210

bed_temperature = 84

before_layer_gcode = ;BEFORE_LAYER_CHANGE\n;[layer_z]\n\n

between_objects_gcode =

bottom_solid_layers = 4

bridge_acceleration = 1000

bridge_angle = 0

bridge_fan_speed = 50

bridge_flow_ratio = 0.95

bridge_speed = 20

brim_width = 0

clip_multipart_objects = 1

compatible_printers_condition =

complete_objects = 0

cooling = 1

default_acceleration = 1000

deretract_speed = 0

disable_fan_first_layers = 3

dont_support_bridges = 1

duplicate_distance = 6

elefant_foot_compensation = 0

end_filament_gcode = "; Filament-specific end gcode"

end_gcode = G4 ; wait\nM104 S0 ; turn off temperature\nM140 S0 ; turn off heatbed\nM107 ; turn off fan\nG1 X0 Y200; home X axis\nM84 ; disable motors

ensure_vertical_shell_thickness = 1

external_fill_pattern = rectilinear

external_perimeter_extrusion_width = 0.45

external_perimeter_speed = 40

external_perimeters_first = 0

extra_perimeters = 0

extruder_clearance_height = 20

extruder_clearance_radius = 20

extruder_colour = #FFFF00

extruder_offset = 0x0

extrusion_axis = E

extrusion_multiplier = 1

extrusion_width = 0.45

fan_always_on = 1

fan_below_layer_time = 20

filament_colour = #FF8000

filament_cost = 0

filament_density = 0

filament_diameter = 1.75

filament_max_volumetric_speed = 8

filament_notes = "List of manufacturers tested with standart PET print settings for MK2:\n\nE3D Edge\nFillamentum CPE GH100\nPlasty Mladeč PETG"

filament_settings_id =

filament_soluble = 0

filament_type = PET

fill_angle = 45

fill_density = 20%

fill_pattern = cubic

first_layer_acceleration = 1000

first_layer_bed_temperature = 84

first_layer_extrusion_width = 0.42

first_layer_height = 0.2

first_layer_speed = 30

first_layer_temperature = 230

gap_fill_speed = 40

gcode_comments = 0

gcode_flavor = marlin

infill_acceleration = 2000

infill_every_layers = 1

infill_extruder = 1

infill_extrusion_width = 0.45

infill_first = 0

infill_only_where_needed = 0

infill_overlap = 25%

infill_speed = 60

interface_shells = 0

layer_gcode = ;AFTER_LAYER_CHANGE\n;[layer_z]

layer_height = 0.2

max_fan_speed = 50

max_layer_height = 0.25

max_print_speed = 100

max_volumetric_extrusion_rate_slope_negative = 0

max_volumetric_extrusion_rate_slope_positive = 0

max_volumetric_speed = 0

min_fan_speed = 30

min_layer_height = 0.07

min_print_speed = 15

min_skirt_length = 4

notes =

nozzle_diameter = 0.4

octoprint_apikey =

octoprint_host =

only_retract_when_crossing_perimeters = 0

ooze_prevention = 0

output_filename_format = [input_filename_base].gcode

overhangs = 0

perimeter_acceleration = 800

perimeter_extruder = 1

perimeter_extrusion_width = 0.45

perimeter_speed = 50

perimeters = 2

post_process =

print_settings_id =

printer_notes = Don't remove the following keywords! These keywords are used in the "compatible printer" condition of the print and filament profiles to link the particular print and filament profiles to this printer profile.\nPRINTER_VENDOR_PRUSA3D\nPRINTER_MODEL_MK2\n

printer_settings_id =

raft_layers = 0

resolution = 0

retract_before_travel = 1

retract_before_wipe = 0%

retract_layer_change = 1

retract_length = 0.4

retract_length_toolchange = 3

retract_lift = 0

retract_lift_above = 0

retract_lift_below = 199

retract_restart_extra = 0

retract_restart_extra_toolchange = 0

retract_speed = 35

seam_position = aligned

serial_port =

serial_speed = 250000

single_extruder_multi_material = 0

skirt_distance = 2

skirt_height = 3

skirts = 1

slowdown_below_layer_time = 20

small_perimeter_speed = 20

solid_infill_below_area = 0

solid_infill_every_layers = 0

solid_infill_extruder = 1

solid_infill_extrusion_width = 0.45

solid_infill_speed = 50

spiral_vase = 0

standby_temperature_delta = -5

start_filament_gcode = "M900 K{if printer_notes=~/.*PRINTER_HAS_BOWDEN.*/}200{else}45{endif}; Filament gcode"

start_gcode = M115 U3.1.0 ; tell printer latest fw version\nM201 X9000 Y9000 Z500 E10000 ; sets maximum accelerations, mm/sec^2\nM203 X500 Y500 Z12 E120 ; sets maximum feedrates, mm/sec\nM204 S1500 T1500 ; sets acceleration (S) and retract acceleration (T)\nM205 X10 Y10 Z0.2 E2.5 ; sets the jerk limits, mm/sec\nM205 S0 T0 ; sets the minimum extruding and travel feed rate, mm/sec\nM83 ; extruder relative mode\nM104 S[first_layer_temperature] ; set extruder temp\nM140 S[first_layer_bed_temperature] ; set bed temp\nM190 S[first_layer_bed_temperature] ; wait for bed temp\nM109 S[first_layer_temperature] ; wait for extruder temp\nG28 W ; home all without mesh bed level\nG80 ; mesh bed leveling\nG1 Y-3.0 F1000.0 ; go outside print area\nG92 E0.0\nG1 X60.0 E9.0 F1000.0 ; intro line\nG1 X100.0 E12.5 F1000.0 ; intro line\nG92 E0.0

support_material = 0

support_material_angle = 0

support_material_buildplate_only = 0

support_material_contact_distance = 0.15

support_material_enforce_layers = 0

support_material_extruder = 0

support_material_extrusion_width = 0.35

support_material_interface_contact_loops = 0

support_material_interface_extruder = 0

support_material_interface_layers = 2

support_material_interface_spacing = 0.2

support_material_interface_speed = 100%

support_material_pattern = rectilinear

support_material_spacing = 2

support_material_speed = 50

support_material_synchronize_layers = 0

support_material_threshold = 45

support_material_with_sheath = 0

support_material_xy_spacing = 60%

temperature = 230

thin_walls = 0

threads = 4

toolchange_gcode =

top_infill_extrusion_width = 0.4

top_solid_infill_speed = 40

top_solid_layers = 5

travel_speed = 120

use_firmware_retraction = 0

use_relative_e_distances = 1

use_volumetric_e = 0

variable_layer_height = 1

wipe = 1

wipe_tower = 1

wipe_tower_per_color_wipe = 15

wipe_tower_width = 60

wipe_tower_x = 180

wipe_tower_y = 140

xy_size_compensation = 0

z_offset = 0

Re: eSUN PETG INI for Slic3r on MK3 ?

Thanks for sharing!

Last question (for now 🙂 )

What do you use for adhesion on the first layer with petg?

I'm testing this https://www.thingiverse.com/thing:1796601 and having difficult to let the cube stay in place...

Re: eSUN PETG INI for Slic3r on MK3 ?

Depending on how much printing you've been doing, perhaps a quick wipe with acetone might be in order. But you would probably notice all materials would be having difficulty sticking in this case. But a quick wipe every so often won't hurt, but remember things will probably "stick like hell" afterward.

After acetone use I would then use Windex prior to PETG printing. This acts as a release agent rather than sticking agent though.

If things aren't sticking so well I wouldn't use Windex, just IPA. If no change then you could give soapy water a go first before the acetone, otherwise I would go with just the acetone.

Having said all the above, are you confident that your z height is ok for PETG? Perhaps you have backed off a bit too much (from your PLA z height)?

Re: eSUN PETG INI for Slic3r on MK3 ?

Good morning Rob,

Good, I've changed 3D object to calibrate the multiplier factor, using a cube with a base and the top open, to measure it as printed.

Easier to print and adhesion ok. Now curves are printed much better.

Now I've got anther time a Shift issue, like the pictuire I've posted some days ago. What could be the cause? Could it possible that without having any z-hop it has hitten a printed part and some steps are missed causing this shift?

And again (as written in a different thread I'll update), I've noticed the bed is not equal in height. I fear this could influence my whole print. These are the support informations:

Y distance from min:

------------------------------

Left: 10.62mm

Right: 10.60mm

Measured skew: 0.03°

------------------------------

Slight skew: 0.12°

Severe skew: 0.25°

[0;0] pint offset

------------------------------

X -0.55mm

Y 0.12mm

I've made some pictures of the skirt of my last print with a macro lens. Look at it:

[attachment=0]IMG_5980[1].JPG[/attachment]

[attachment=1]IMG_5979[1].JPG[/attachment]

So something IS wrong...

I've updated Firmware from 3.1.2 to 3.2.1. No recalibration was asked. And previously I've done a calibration.

Shoud a fresh XYZ calibration help even if done before updating firmware?

Thanks,

Simon

Re: eSUN PETG INI for Slic3r on MK3 ?

Actually I don't think it does do re-calibration for that change, but if you can bear it it probably wouldn't hurt to perform a firmware reset. This will force a calibration.

As for the layer shift I have printed 12 bolts at once with those settings and all printed fine so I don't think its the z lift.

Is the layer shift occurring on just one or two models? If so then I would run the stl file/s through a checker just to make sure it isn't missing some layers. And can you film the printing so that you can see what happens? It could be something easily fixed like a belt too tight for example.

Also, those models look like they may be suffering a bit from over extrusion. Perhaps drop the extrusion multiplier down a bit?

Good luck.