Drooping exterior perimeter

Hey,

I'm new to 3d printing and already ended up on this forum maybe 50 times, so thank you for all the help.

Background:

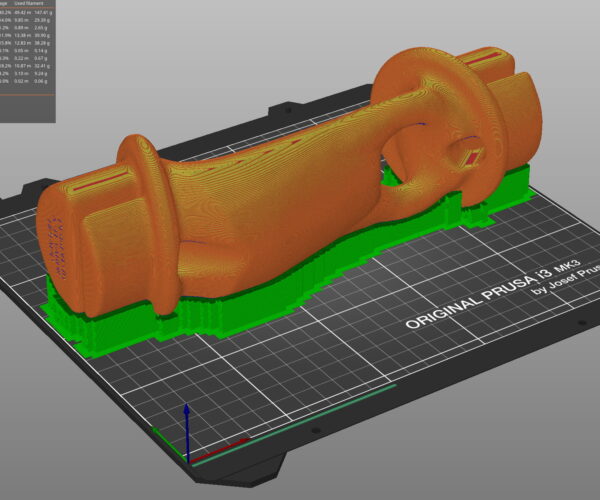

Finished building my first printer (i3 mk3s+) a week ago and am trying to optimise printing a product I've designed earlier. First prints of it came out well apart from some having a single x-shift at some height under first half (product is cylindrical in nature and has to be printed on its side for strength reasons as it is a training handle). Disabling crash detection took care of that after I of course did the recommended hardware checks. A print time of 17h 43min was too long, however, so I started to push for more speed after learning more about slicing.

Current problem:

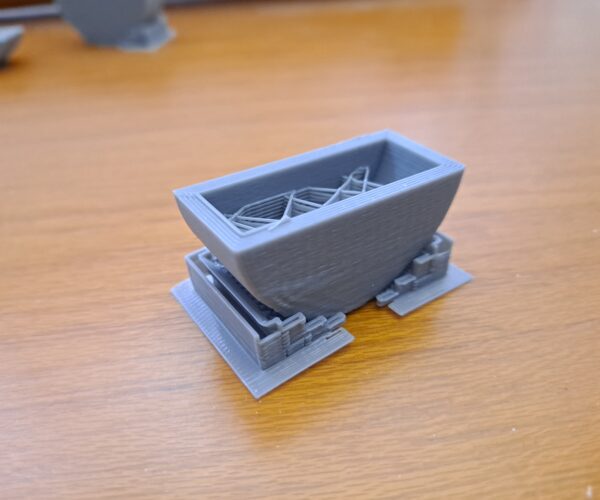

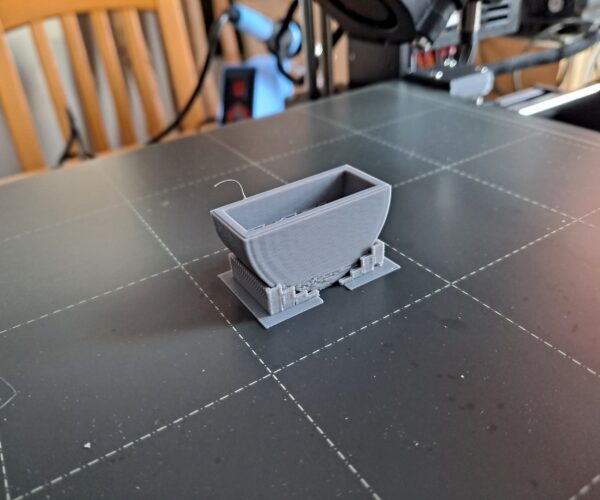

On the standard 0.4mm nozzle I pushed extrusion width to 0.6mm, layer height to 0.4mm and the speeds higher to get close to the 11.5mm^3 flow rate as often as possible. Top half of the handle (no overhangs) always prints flawlessly, but the underside had drooping exterior perimeter lines even when "inside" the printed rectangular supports. Print times were down to 9-10hours, though, and all my other requirements were checked (high strength, weight under 320 grams so that I can print 3 from a single 1kg roll without worry). Instead of wasting more time on full prints, started to troubleshoot on small short cylinders. On this 8th attempt I have:

matched flow rate of printing each feature on a slice so they are close to same color, no change

dropped layer height back to 0.32mm, no change

disabled printing a bridging infill between perimeter and support which was always blue (printing at about half the flow rate), no change

Any help in narrowing down the problem is greatly appreciated.

RE: Drooping exterior perimeter

I'm new to 3d printing

Then i suggest to stay with the predefined print profiles, as they give you satisfying results in most cases.

If you plan to print mostly technical parts without very fine details, consider to use a 0.6 nozzle as standard.

Printing with 0.4 layer hight and a 0.4 nozzle is not recommended. Layer height should be max. 70% of nozzle diameter.

You can read a very good explanation about the overhangs topic here (though your overhang does not start on the build plate):

RE:

Agreed, reinstate defaults. Don't look for speed until the part is printing OK.

When designing for 3D printing never put curves or shallow overhangs against the print sheet... That curve would print OK if you invert the part on the sheet but you would have to do something about the step on the flat face ... if it's for registration then change it for a 45degree chamfer.

Cheerio,

RE: Drooping exterior perimeter

The first prints did print perfectly with the default profile, though I did of course add perimeters and different amounts of infill for strength reasons. And even when pushing for speed as I learned more, the top 60% of the cylinder printed perfectly, so only the overhangs are the issue even if they are supported. I was hoping someone knew the main factors that cause such drooping so I could fix those and keep the rest of the speed. Not much to learn if printing with just default profiles 😀 I will get 0.6 and 0.8 nozzles, but meanwhile I'd like to print few more of these before friday for sale, and 17h 43min per handle is just too slow. The handle itself looks like this, and forces applied will try to snap it in half in y or z directions, which is why it must be printed on its side. I will not be sharing the file of that, the cylinder is enough to replicate the issue.

RE: Drooping exterior perimeter

Not much to learn if printing with just default profiles

I print since 3 years now and am still very careful when making deviations from the default profiles. 😀

There are so many factors playing together that you cannot predict the outcome reliably. Did you read the link above?

Printing this big part with a 0.4 nozzle is a mistake.

Get a 0.6 or 0.8 Bondtech CHT nozzle. Printing with a big nozzle makes parts noticeably stronger, too.

Stronger than printing the same wall thickness with a smaller nozzle and more perimeters.

RE: Drooping exterior perimeter

Thanks, I read it and while I print in PLA it mentions some useful things, such as the purple solid infill causing problems which is what I've suspected, but it can't be removed even if I add 7 perimeters at 0.6mm each. Drooping always happens at portions where solid infill is added. And that infill is caused by the extreme angles and even adding support won't help because it deforms inside the support too. Maybe the only solution is to ripcut the model in half and glue it together... could probably get away with 0 support and even less partial infill.

RE: Drooping exterior perimeter

print few more of these before friday for sale

yoe should not hurry and try to print this thing for sale if it is not ready for sale.

Get the bigger nozzle, print with a layer height that fits for the nozzle, for example 0.3 for a 0.6 nozzle. Lower layer height will reduce the drooping.

I repeat, 0.4 nozzle is nearly a mistake for this part.

And PLA is not a good choice for mechanical parts, too. Unless it is some kind of "ST" type (ESUN PLA-ST)

RE: Drooping exterior perimeter

Getting the nozzles takes a week, and the few I've printed so far I'm absolutely unable to break, and am also adding polyurethane on top. They only have cosmetic flaws, and I'll be selling them in person so no one will have any surprises. PLA seems to easily be strong enough for this stuff. Thanks for the help, seems that splitting the model in two is the only way to print it reliably. Did a cylinder test with a default DRAFT preset and even that warped in the supports, so it has to be caused by the overhangs which seems only problematic due to the obligatory solid infill (otherwise what is the point of supports?).

For a part like this printing halves and joining them may be the best way to go.

Also, for tecnical parts, designing tailored support in the source file is preferred. The slicer-generated default supports are always going to be a compromise.

Cheerio,

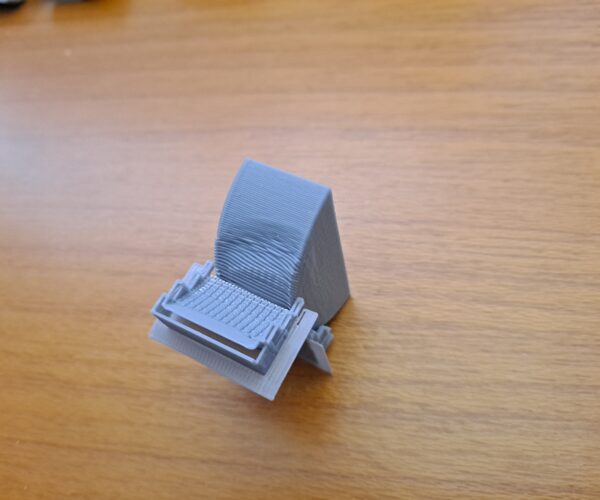

RE: Drooping exterior perimeter

Printed one set of halves and while I can go fast, there was a slight bow to the bottoms so I had to use 3 clamps to glue them together. It printed the dowels (2.6 alpha cause I wanted the pegs) but didn't cut the holes probably because the hole cutters stood in the air after the halves were placed on ground. Rather than fiddling with epoxy and always having a very visible seam, I'll print a couple more droopy ones, fix them with a soldering iron and sand them smooth before I get a bigger nozzle.

What is the reason a custom support would support the overhangs better than a generated grid support would? I'm quite sure it's the exterior perimeter that is falling off due to the purple solid infill distorting the inner perimeters, and unless a support is fusing into every single layer, in my mind it would still droop into any gap between the perimeter and support. Can't find any info on what such supports would look like, so could you point me somewhere? Thank you for the tips.