Re: Does someone want to know how fast they can print/extrude? look here

Nice. 🙂 Well I am up and running with my new copper plated V6 block and 0.4mm nozzle now I have a new thermistor.

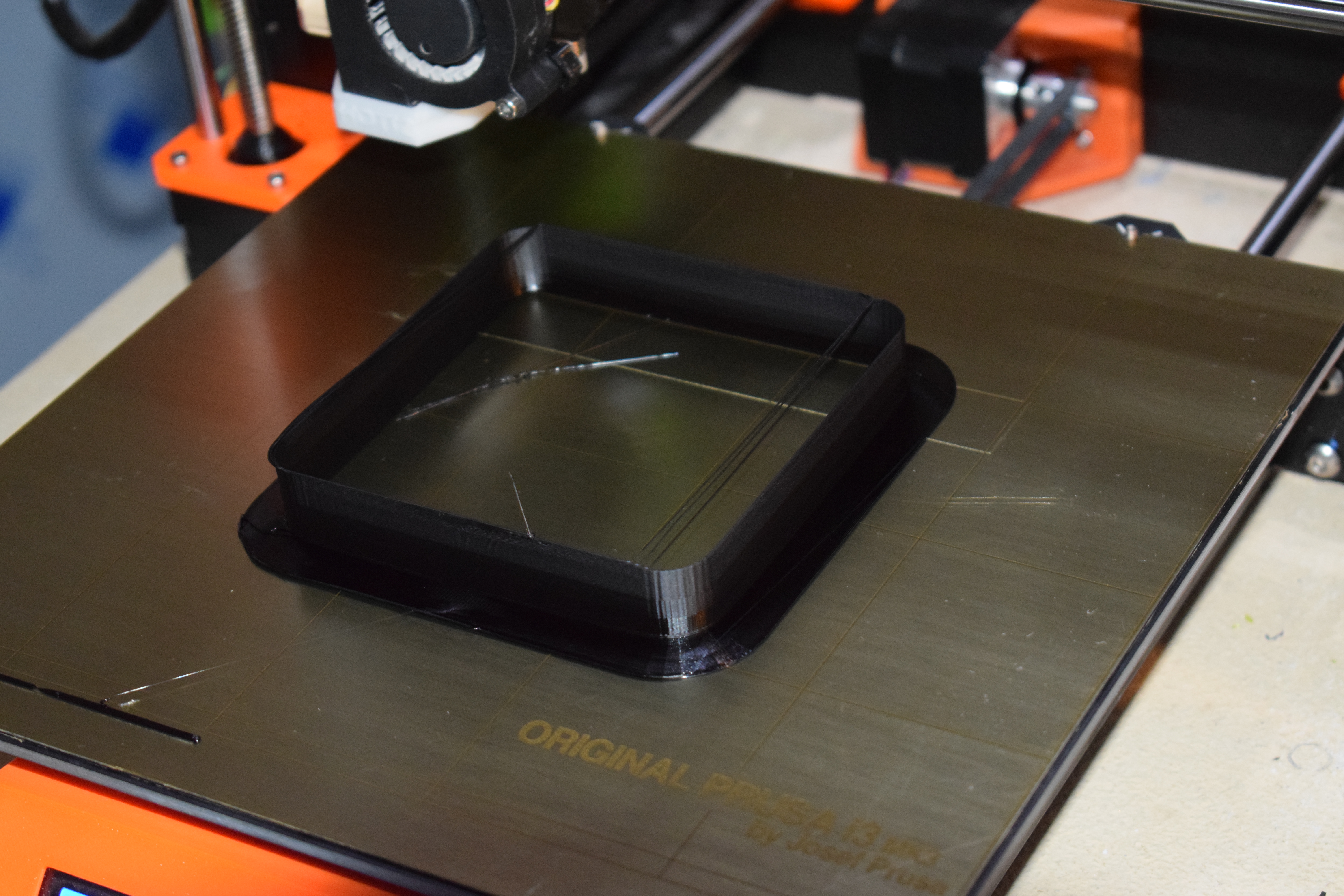

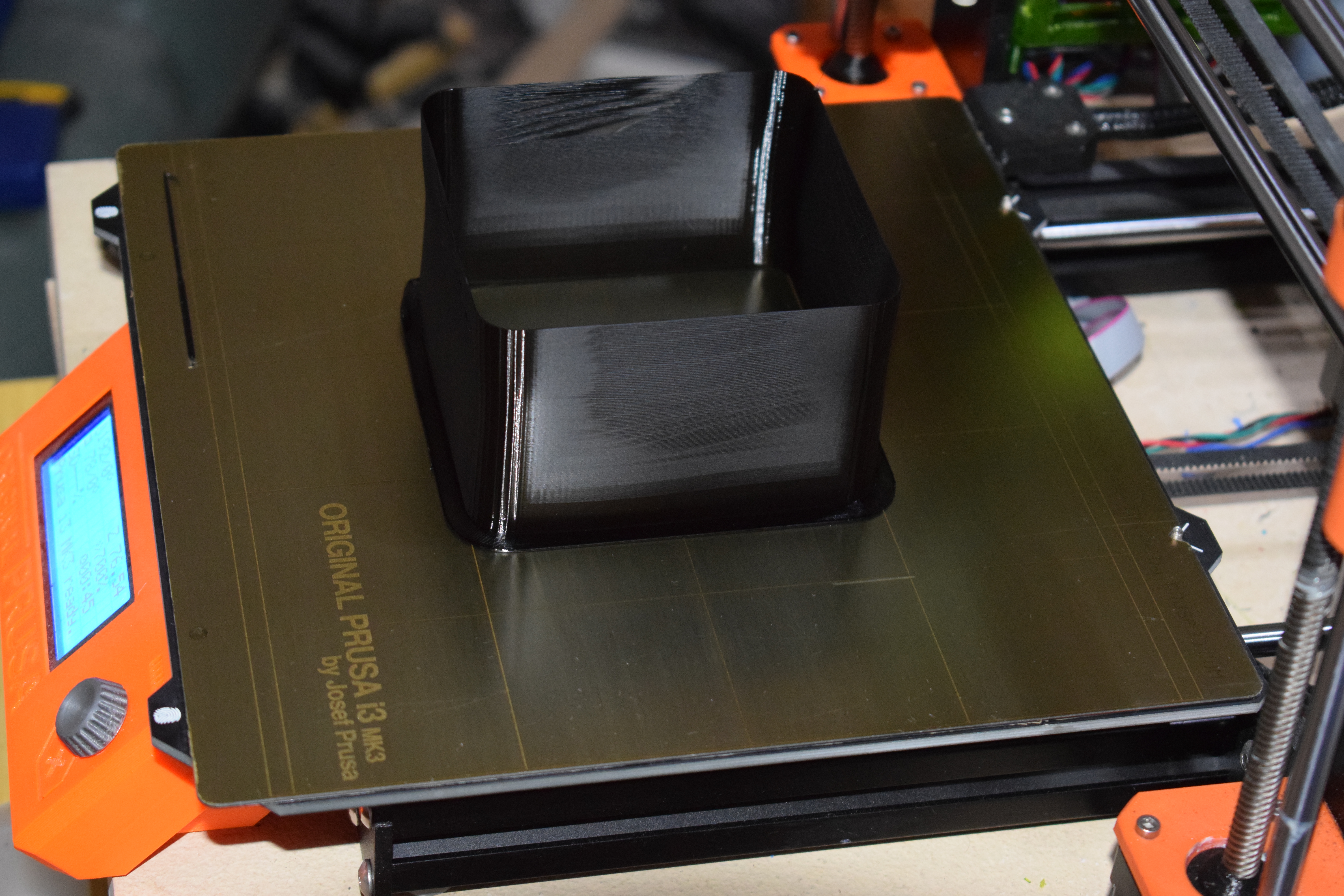

So I may run some tests tomorrow. Got to print a new Eisny box first modified for the woven wrap on the extruder cable bundle.

Regards,

Martin

Martin Wolfe

Re: Does someone want to know how fast they can print/extrude? look here

change in configuration_prusa.h

#define DEFAULT_MAX_ACCELERATION {4000, 4000, 200, 5000} // (mm/sec^2) max acceleration (M201)

#define DEFAULT_MAX_FEEDRATE {500, 500, 12, 120} // (mm/sec) max feedrate (M203)

I did make these changes to the 3.2.1 firmware, recompiled and uploaded the hex file to the Prusa I3 MK3 controller, but when I re-ran your test just now, it became clear that it still never went faster than the 175mm/sec layer speed. 🙁

So, it would now appear I never got to the earlier speeds of 200mm/sec or 225mm/sec on my own test object either. 😥

Argh... 😥 😥 😥

So, what's holding it back? i.e. What else needs to be changed so that it can go faster? ❓

Re: Does someone want to know how fast they can print/extrude? look here

I think I may have found the limitation.

; generated by Slic3r Prusa Edition 1.40.0-beta+win64 on 2018-06-11 at 19:52:01

;

; external perimeters extrusion width = 0.45mm

; perimeters extrusion width = 0.45mm

; infill extrusion width = 0.45mm

; solid infill extrusion width = 0.45mm

; top infill extrusion width = 0.40mm

; first layer extrusion width = 0.42mm

M107

M115 U3.2.1 ; tell printer latest fw version

M201 X4000 Y4000 Z200 E5000 ; sets maximum accelerations, mm/sec^2

M203 X400 Y400 Z12 E120 ; sets maximum feedrates, mm/sec

If could be the extruder feed rate. In the GCode its maximum is set to 120mm/s. This is still the default Slic3r value so double it to 240 and see what happens. The new line would be:-

M203 X400 Y400 Z12 E240 ; sets maximum feedrates, mm/sec

Regards,

Martin

Martin Wolfe

Re: Does someone want to know how fast they can print/extrude? look here

I think I may have found the limitation.

; generated by Slic3r Prusa Edition 1.40.0-beta+win64 on 2018-06-11 at 19:52:01

;

; external perimeters extrusion width = 0.45mm

; perimeters extrusion width = 0.45mm

; infill extrusion width = 0.45mm

; solid infill extrusion width = 0.45mm

; top infill extrusion width = 0.40mm

; first layer extrusion width = 0.42mm

M107

M115 U3.2.1 ; tell printer latest fw version

M201 X4000 Y4000 Z200 E5000 ; sets maximum accelerations, mm/sec^2

M203 X400 Y400 Z12 E120 ; sets maximum feedrates, mm/sec

If could be the extruder feed rate. In the GCode its maximum is set to 120mm/s. This is still the default Slic3r value so double it to 240 and see what happens. The new line would be:-

M203 X400 Y400 Z12 E240 ; sets maximum feedrates, mm/sec

Regards,

Martin

Thanks for the suggestion. I just now tried it. Unfortunately, it had no effect.

Re: Does someone want to know how fast they can print/extrude? look here

There are a few hard limits in the firmware, look at my thread here again

https://shop.prusa3d.com/forum/hardware-firmware-and-software-help-f64/what-values-do-i-need-to-change-in-the-firmware-in-t18812.html

There's also //Normal mode limits

I've left the values there as i've written in the post for my current fimware, and will increase a few when the next firmware comes. step by step, not too much

Increased a few hard set values in my last firmware that messed up bed level calibration and endstop calibration (unfortunately i do not know which ones messed it up, changed all of them)

I'm not a software guy, so i can't be of more help here, and nobody else besides you and me is contributing

There's also the fact that an i3 will print like garbage if you increase the jerk/acceleration, and the fact that some values are hard set and are used by endstop/mbl settings on the MK3 with the TMC's, and the fact that the Z axis assembly is a wobbly POS which is why the MK3 is currently as slow as it is.

Re: Does someone want to know how fast they can print/extrude? look here

There are a few hard limits in the firmware, look at my thread here again

https://shop.prusa3d.com/forum/hardware-firmware-and-software-help-f64/what-values-do-i-need-to-change-in-the-firmware-in-t18812.html

There's also //Normal mode limits

I've left the values there as i've written in the post for my current fimware, and will increase a few when the next firmware comes. step by step, not too much

Increased a few hard set values in my last firmware that messed up bed level calibration and endstop calibration (unfortunately i do not know which ones messed it up, changed all of them)

I'm not a software guy, so i can't be of more help here, and nobody else besides you and me is contributing

There's also the fact that an i3 will print like garbage if you increase the jerk/acceleration, and the fact that some values are hard set and are used by endstop/mbl settings on the MK3 with the TMC's, and the fact that the Z axis assembly is a wobbly POS which is why the MK3 is currently as slow as it is.

I apologize if this question may be duplicative with what you may have already said somewhere, but I just need to be clear: what's the highest speed you yourself have been able to run your own speed test at, and what were the settings you used at that time? If you have the settings you used to get the 350mm/sec speed you reported earlier, then that's good enough for now.

Also, when you said you could print at 350mm/sec, how do you actually know that? I'm just wondering if you might have fallen into a similar trap to the one I just did, or if you have some other way of knowing/measuring.

Re: Does someone want to know how fast they can print/extrude? look here

For reference my current settings for Rigid Ink PETG are 225/235 C, K factor of 60 and an extrusion multiplier of 1.18. This is down from 240/245, K factor of 45 and a multiplier of 1. Once I am back in action I will need to check my extrusion levels with a micrometer but I do not expect to have to change my K and extrusion much.

Well the plated copper 0.4mm nozzle with the plated copper V6 block, Capricorn tubing replacing the main PTFE tube and a titanium heatbreak have had a big impact. Unfortunately I had to replace my thermistor so it may not be reading quite the same as the old one. However my new settings for Rigid Ink PETG are 220/230C, K factor of 45 (back to the Prusa PETG default) and an extrusion multiplier of 1.1. Had to lower the temperature as the filament was just dropping out of the nozzle with the slipper extrusion path.

All in all that is a very worth while change that has introduced a fair bit of headroom for speed tests. Now I just need to see how fast I can push it while maintaining quality.

Regards,

Martin

Martin Wolfe

Re: Does someone want to know how fast they can print/extrude? look here

That's good news, Martin. This is the first I've heard of a titanium heatbreak. Is it this one? https://e3d-online.com/titanium-heat-break

I made two changes to the configuration_prusa.h file, one inspired by you and one taken from an earlier posting on a different thread by DevilHunter. The one by you (the 240 number) is:

#define DEFAULT_MAX_FEEDRATE {500, 500, 12, 240} // (mm/sec) max feedrate (M203)

and the one by DevilHunter is:

#define NORMAL_MAX_FEEDRATE 350

One or both of them had the positive effect of increasing the highest print speed. I lost count of the layers, but it's now either 275mm/sec or 300mm/sec, assuming we can trust a change in the pitch of the motors as an indication of actual speed. However, beyond that, there's no more change in motor pitch as it goes up. So, it's some improvement over what was before, but how much of an improvement in actual speed (as opposed to theorized speed) I can't really say for sure.

Re: Does someone want to know how fast they can print/extrude? look here

That's good news, Martin. This is the first I've heard of a titanium heatbreak. Is it this one? https://e3d-online.com/titanium-heat-break

I made two changes to the configuration_prusa.h file, one inspired by you and one taken from an earlier posting on a different thread by DevilHunter. The one by you (the 240 number) is:

#define DEFAULT_MAX_FEEDRATE {500, 500, 12, 240} // (mm/sec) max feedrate (M203)

and the one by DevilHunter is:

#define NORMAL_MAX_FEEDRATE 350

One or both of them had the positive effect of increasing the highest print speed. I lost count of the layers, but it's now either 275mm/sec or 300mm/sec, assuming we can trust a change in the pitch of the motors as an indication of actual speed. However, beyond that, there's no more change in motor pitch as it goes up. So, it's some improvement over what was before, but how much of an improvement in actual speed (as opposed to theorized speed) I can't really say for sure. Subjectively speaking, I don't think the true delta increases in speed between the later layers was as great as the delta in speeds at the lower layers, if you know what I mean. On the other hand, I didn't hear any sounds of stepper motor skipping, so maybe they really were.

I'll be very interested to hear your opinion on all this once you catch up.

As for me, I'm not sure what more I can do right now, as I seem to have hit this new limit.

[Oops. Sorry for quoting myself. I meant to edit it instead. Unfortunately, there's no way to delete the earlier post now that I've done it.]

Re: Does someone want to know how fast they can print/extrude? look here

That's good news, Martin. This is the first I've heard of a titanium heatbreak. Is it this one? https://e3d-online.com/titanium-heat-break

Yes it is. I brought it for the improved strength rather than the thermal properties. The default one that Prusa supplies can't really handle the pressures the extruder throws at it and the thin walls bow outwards. It was causing prints with a lot of retractions to fail.

Regards,

Martin

Martin Wolfe

Re: Does someone want to know how fast they can print/extrude? look here

I apologize if this question may be duplicative with what you may have already said somewhere, but I just need to be clear: what's the highest speed you yourself have been able to run your own speed test at, and what were the settings you used at that time? If you have the settings you used to get the 350mm/sec speed you reported earlier, then that's good enough for now.

350mm/s for infill, but only for big objects, and only for fun, not for actual prints.

Filament will rip there, will look like if you go above 180mm/s on the standard prusa hardware, infill will rip everywhere and not bond to the outer walls.

150mm/s infill with fatter layers (speed: infill, 0.6mm) and infill every second layer (infill: combine every 2 layers) are more useful)

Harder, fatter, faster, stronger infill 🙂

Still experimenting with this.

PETG doesn't like it, but PLA does.

now, 300+mm/s non print moves on the other hand, are more useful.

Here's what the geniuses at dyze design coocked up:

https://dyzedesign.com/2016/10/printing-300-mm-s-part-1-basics-hardware/

https://dyzedesign.com/2016/11/printing-300-mm-s-part-2-calculations/

https://dyzedesign.com/2017/03/printing-at-300-mm-s-part-3-firmware-tests/

have a look at all these topics, they are awesome. Part 3 XY move tests is what you are capable of.

Also, when you said you could print at 350mm/sec, how do you actually know that? I'm just wondering if you might have fallen into the same trap I just did, or if you have some other way of knowing/measuring.

The only way other than by sound measuring this would be by high speed camera (an iPhone is ok for this), and count the frames against time to see what speed you actually move.

Easier but more unreliable is by sound.

The default one that Prusa supplies can't really handle the pressures the extruder throws at it and the thin walls bow outwards. It was causing prints with a lot of retractions to fail.

I, err, what? Sorry but i call bull.

The reason MK3 folks are having trouble with the new standard e3d heatbreaks is some added bore step at Prusa's request for the MMUV1 compared to the old MK2 era ones. Or it's because they've updated their 'engineered roughness' as they like to call it inside the heatbreak compared to a few years ago. They've mentioned they can't totally polish their heatbreaks inside, and have to make it slightly rough inside, why i never found out.

Folks of E3D are aware and plan to release new heatbreaks, nozzles, heaterblocks with a special anti stick anodized coating in the coming weeks. Waiting on this before i throw out my money for yet another single digit improvement in hardware.

Titanium heatbreak won't do you any good expect if you print PEI with 500 degrees.

Or it's for the brutes who like to snap their heatbreak necks while tightening the nozzles.

Re: Does someone want to know how fast they can print/extrude? look here

They've mentioned they can't totally polish their heatbreaks inside, and have to make it slightly rough inside, why i never found out.

In this video:

the E3D guy claims that if they make the inside too smooth, then the filament actually sticks to it more, and that their "engineered roughness" is to reduce friction. Now, as to whether that's true or baloney, I have no idea, but that's their explanation. Maybe it's just an attempt to further differentiate themselves from the Chinese knockoffs.

Not sure what products are on the horizon, but the titanium material seems like a good choice over what else is currently available. I accidentally bent my Prusa heatbreak before I realized how fragile it was, and I replaced it with a micro swiss, mainly because people on this forum were lauding it. If I had known about the titanium option, I think I would have gone for it.

Re: Does someone want to know how fast they can print/extrude? look here

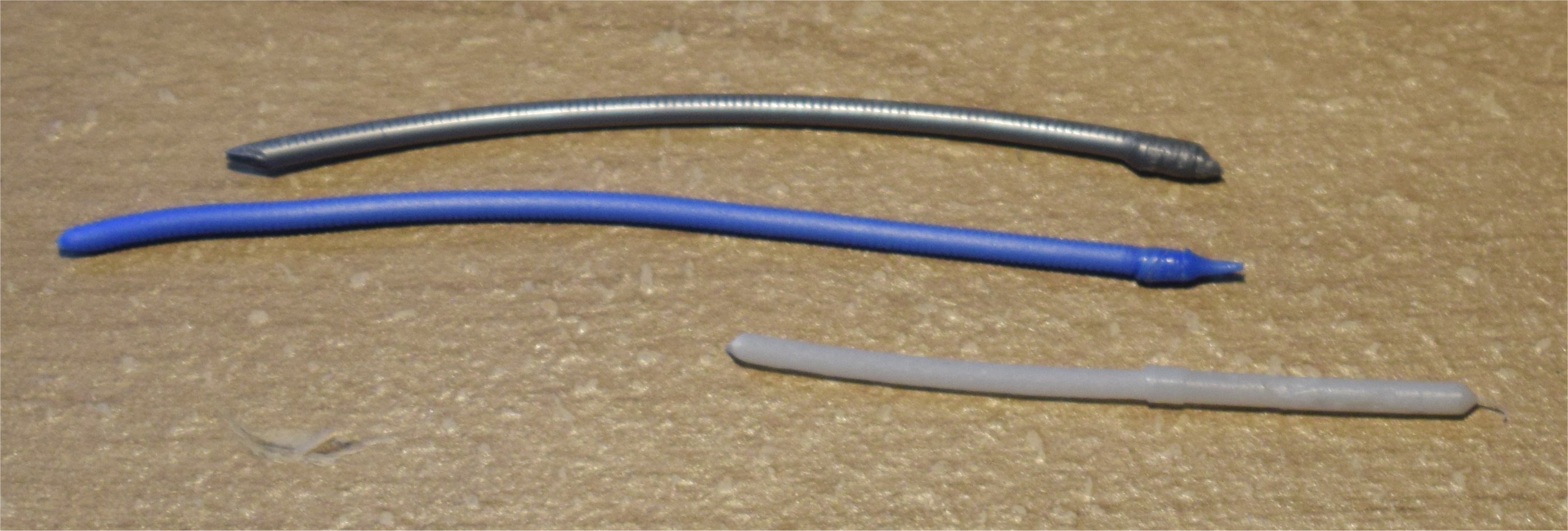

The evidence was in the cold pulls I did. The part that corresponded to the heartbreak part of the heatbreak was over 2mm in diameter.

The top two are from standard unloading with my old heat break and the bottom one is a cold pull.

An Unload From The New Settup

Regards,

Martin

Martin Wolfe

Re: Does someone want to know how fast they can print/extrude? look here

The evidence was in the cold pulls I did. The part that corresponded to the heartbreak part of the heatbreak was over 2mm in diameter.

Did a cold pull just now with the standard Prusa heatbreak (no red neck)

Long nozzle part measures 2.00mm, the slight sharp bump measures 2.48mm, then the heatbreak part measures 2.00mm, then comes the step inside the cold part of the heatbreak with 2.09mm. Above there is the 1.75mm filament

The big ring is where the champfer is on the nozzle and the champfer of the heatbreak.

a bit weird, since i currently don't know how a 2.48mm part can fit through a 2.00mm part during a cold pull, but perhaps the little air bubbles on the backside deformed this somehow.

Bit it was always like this, on the hundreds of cold pulls i did. Perfect nozzle imprint, bigger ring, perfect heatbreak. half of them had these air bubbles.

Side note: i find cold pulls harder to do on the Volcano nozzles, it sticks more to them now, and holf of the time the filament breaks off.

With the standard V6 nozzles it wored every time around 90 degrees, the volcano nozzles sometimes like a lower temperature, around 85 degrees, sometimes a higher one around 95 degrees. Haven't found the sweet spot yet for the Volcano cold pulls.

Re: Does someone want to know how fast they can print/extrude? look here

I have now run my first test. For this one I keep the temperature at 230, the fan at 30%-50% and K45. Basically except for the speed and a maximum volumetric flow of 120mm³/s the settings I print Rigid Ink PETG now.

It showed signs of starting to fail at 150mm/s and did fail at the corners at 200mm/s.

I made a change to the gotta go fast G-Code. So I could use the 0.3mm first layer and the 0.2mm Z offset I print PETG at. The GCode will now work for any layer height and Z offset.

;AFTER_LAYER_CHANGE

;Layer Z value [layer_z]

; gotta go fast

;Layer number [layer_num]

{if (layer_num - (layer_num / 25) * 25) == 0}M220 S{layer_num*2+100}{endif}

Regards,

Martin

Martin Wolfe

Re: Does someone want to know how fast they can print/extrude? look here

For this test I made 2 changes.

Now the results.

100mm/s full glossines was achieved. The previous test was not quite there.

150mm/s still very glossy but starting to fade.

200mm/s gloss is reduced but good enough for a draught print

250mm/s is good enough for infill

300mm/s under extrusion is starting to show but the layers are still bonding

350mm/s under extrusion is in full force but bonding. This however is unacceptable even on infill

500mm/s Layer bonding breaks down and extrusion becomes wispy.

All in all at 245°C and the reduced X and Y jerks of 5 a major speed increase is achieved with a top quality print achievable with

Perimeters 150mm/s

Small perimeters 40mm/s (Or lower to eliminate jerk effects)

External perimeters 100mm/s

Infill 250mm/s

Solid Infill 150mm/s

Top solid Infill 100mm/s

Support material 300mm/s (Make use of that under extrusion)

Bridges 100mm/s (Should be able to bridge longer distances with a higher bridge fan :))

Gap fill 150mm/s

All in all a major increase in speed. The infill volumetric rate calculates as 39.7mm³/s rounded down to 1dp.

Regards,

Martin

Martin Wolfe

Re: Does someone want to know how fast they can print/extrude? look here

Using K=50, I did DevilHunter's speed test print:

Assuming a change in pitch is an accurate proxy for speed, then at the topmost layer it achieved 300mm/sec. However, the pitch stopped changing after that, and so I presume the speed remained constant at 300mm/sec after that. i.e. I've hit another limit of some kind.

Re: Does someone want to know how fast they can print/extrude? look here

300mm/s under extrusion is starting to show but the layers are still bonding

350mm/s under extrusion is in full force but bonding. This however is unacceptable even on infill

500mm/s Layer bonding breaks down and extrusion becomes wispy.

Apparently you were not affected by the 300mm/sec limit that I've encountered. Did you make any other changes to the firmware or gcode to get to those 350mm/sec and 500mm/sec speeds? Is 500mm/sec a typo?

Are you printing at 0.2mm layer height and 0.48mm extrusion width, or, if not, what?

Re: Does someone want to know how fast they can print/extrude? look here

My final test was also at K=60.

The artefact near the top of 200mm/s is where the filament sensor played up and forced me to do a reload. All the layers bonded so that was an improvement.

300mm/s if fully bunded and without an extrusion problems.

350mm/s extrusion problems are starting to show.

550-600 I did not hear any change in speed between these two. As I did here a change between 500 and 550mm/s I assume my peek speed was somewhere in that range.

As the K value had been played with to get this print I took a pair of callipers to it. 100mm/s perfect. 0.45mm wall thickness throughout. At over 500mm/s 0.45mm near the corners and 0.61mm in the middle of the run.

So in conclusion although a K value of 60 will enable prints of poor quality to be made at 500mm/s in reality 300mm/s is the fastest I can print PETG with my setup and that speed is only good for supports when the reduced layer bonding is a benefit.

Regards,

Martin

Martin Wolfe

Re: Does someone want to know how fast they can print/extrude? look here

100mm/s full glossines was achieved. The previous test was not quite there.

150mm/s still very glossy but starting to fade.

200mm/s gloss is reduced but good enough for a draught print

250mm/s is good enough for infill

300mm/s under extrusion is starting to show but the layers are still bonding

350mm/s under extrusion is in full force but bonding. This however is unacceptable even on infill

500mm/s Layer bonding breaks down and extrusion becomes wispy.

Looks as though you are counting each layer as increasing by 50mm/sec, whereas I've been counting them as increasing by 25mm/sec. I guess we should both double check the gcode, as we can't both be right. That might explain how you got to 500mm/sec, whereas your speed test print doesn't look as though it's that high.