Re: Does someone want to know how fast they can print/extrude? look here

I tried devilhunter's deskfan idea just now, but not long after the brim was laid and the real test begun I got the infamous "thermal runaway" error message. Therefore, I may have to employ the dreaded silicon sock (of which I have two remaining) to carry that idea forward. Either that, or, maybe better, try first doing a PID calibration while the fan is blasting away. If that doesn't work, then I think upgrading to the 40w heat cartridge might be justified. One of the forum members pointed out that the heat cartridges can be driven at even higher watts, so if push comes to shove, even that might be a possibility, though it would require higher than 24v to do it.

Martin's idea of lowering the acceleration speed makes sense to me. Very insightful! I'd wager that will certainly help.

I must say, it is truly a pleasure having the two of you looking over my shoulder and providing commentary. Thank you very much!

Re: Does someone want to know how fast they can print/extrude? look here

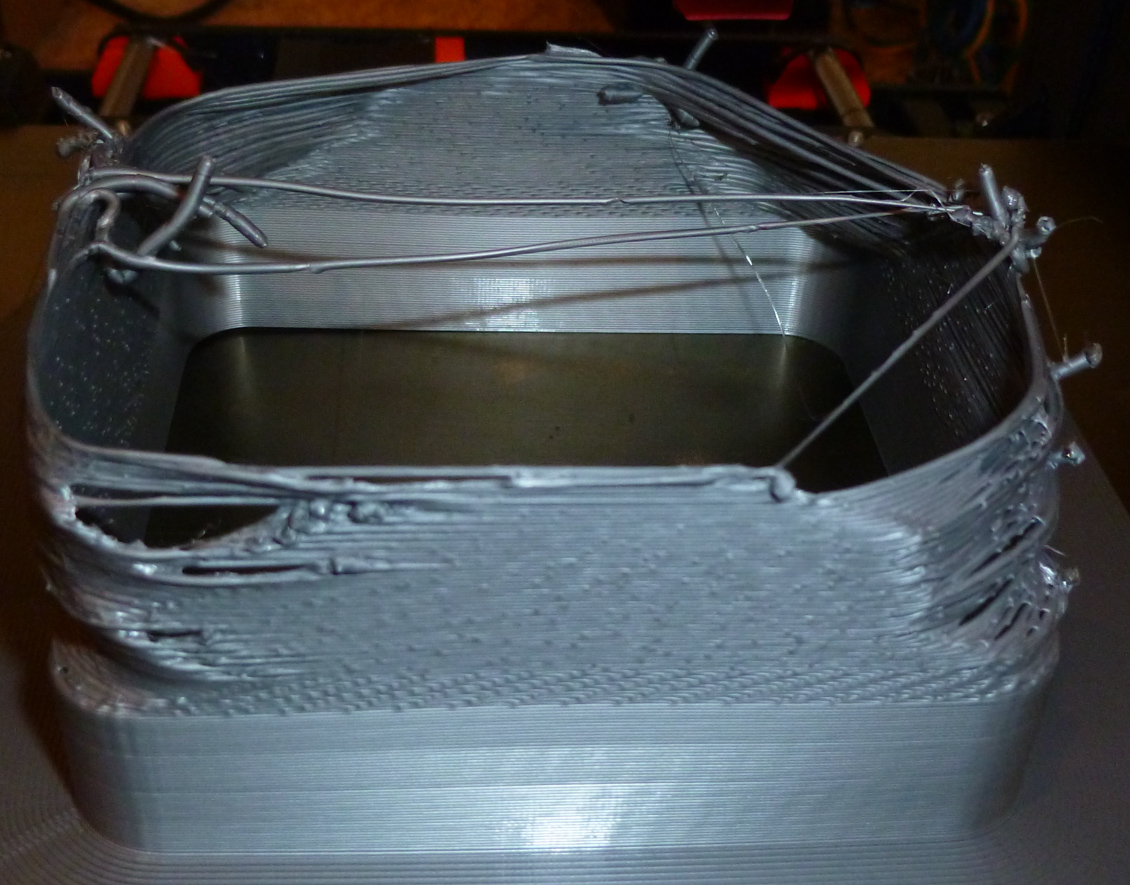

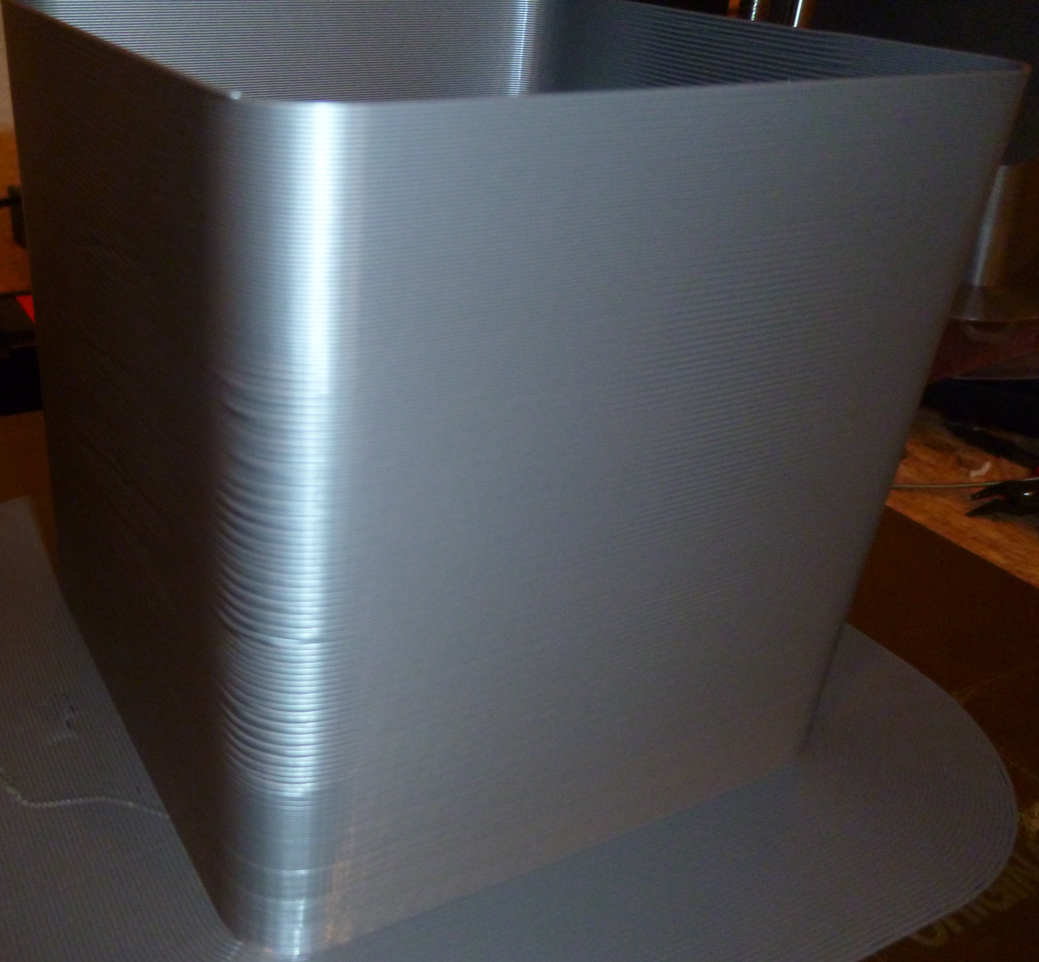

Autotuning the PID with a strong fan but without the silicon sock just wasn't enough to maintain the hot end temperature, so I put on a silicon sock again, and then it worked. I used a pretty strong fan, but that also wasn't enough:

So, I think Martin is right: the only way to build this thing higher will be to reduce the accelerations. 🙁

Re: Does someone want to know how fast they can print/extrude? look here

Maybe (?) this is old news,but I just now noticed that E3D also makes a copper Volcano: https://www.filastruder.com/collections/e3d-spare-parts-and-accessories/products/e3d-copper-volcano-kit

so I imagine that would allow even higher volumetric extrusion, even though the above results suggest that does not appear to be the limiting factor at this particular moment. I suppose to maximize the benefits, you might want to pair it with a copper nozzle as well.

Anyone here tried it?

Re: Does someone want to know how fast they can print/extrude? look here

Maybe (?) this is old news,but I just now noticed that E3D also makes a copper Volcano

*Starts swearing*

I ordered my Volcano block on 4th June. At that time they told me that it was in the works but no ETA. Oh well it is only £18.00 wasted for the Aluminium block. The UK price with VAT for the copper one is £28.80

Regards,

Martin

Martin Wolfe

Re: Does someone want to know how fast they can print/extrude? look here

Maybe (?) this is old news,but I just now noticed that E3D also makes a copper Volcano

*Starts swearing*

I ordered my Volcano block on 4th June. At that time they told me that it was in the works but no ETA. Oh well it is only £18.00 wasted for the Aluminium block. The UK price with VAT for the copper one is £28.80

Regards,

Martin

darn it, same boat here.

I do wonder about the plated copper stuff for PLA and PETG though.

I mean shooting cannon balls at birds:

Aluminum Block (~230W/(m•K) -> Brass Nozzle (~120W/(m•K) -> PLA material (0.13 W/m•K) / PETG material (0.29 W/m•K)

Copper Block (~400W/(m•K) -> Copper Nozzle (~400W/(m•K) -> PLA material (0.13 W/m•K) / PETG material (0.29 W/m•K)

There is a noticeable slight improvement when going from brass nozzles to plated copper nozzles, but most of it comes from the plated part, the filament won't stick to it as much as normal nozzles, resulting in a slightly better surface finish.

If this stuff is doing us any good when printing with a low temperature (250C vs 500C), combined with the relatively short distance the filament can heat up with (around 2cm), i would guess that you could only see an 5% improvement for normal printing.

I'm still waiting for E3D's wonder coating that they promised since beginning of the year, they've found a coating material that is supposedly not let filament stick to it. They said they would coat nozzles, heaterblocks, heatbreaks and silicone socks with it. 6 Months later, it's still not here.

Autotuning the PID with a strong fan but without the silicon sock just wasn't enough to maintain the hot end temperature, so I put on a silicon sock again, and then it worked. I used a pretty strong fan, but that also wasn't enough:

So, I think Martin is right: the only way to build this thing higher will be to reduce the accelerations. 🙁

I wonder what could be done to make your case better, or what limits you.

The gcode is showing the practical speeds you can print with, and to think you can print with a 0.8mm nozzle at 100mm/s reliably, that's not bad at all.

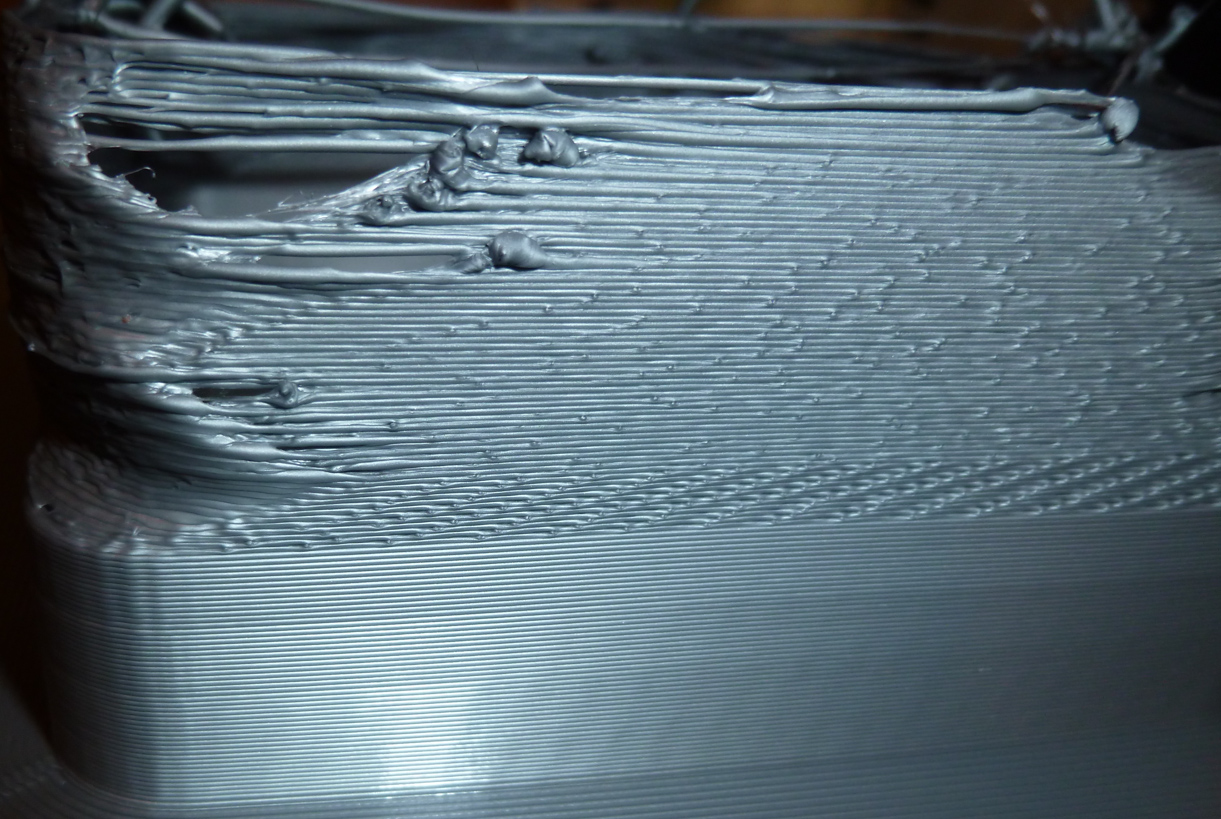

But somethings generally wonky with your speeds above 100mm/s from those photos, why does it collapse inwards like that?

Re: Does someone want to know how fast they can print/extrude? look here

The main reason I wanted the copper plated block was stop splashes from PETG sticking to it and also to make it easier to clean when I finally have my second blob of doom. My main reason for getting the volcano is to be able to print materials like PETG and HIPS at the bottom of their range. With the conventional block/nozzle the temperature has to be way up to make sure it is heated all the way through.

The inward collapse is caused by the start of the corners not adhering enough by the time the print moves to the straight run. Which is why I recon that the acceleration needs to be lowered so that it spend more time on the changes of direction. That certainly worked as I said getting PETG first layer properly tuned in. The straight runs can go at full speed as they will be help in place by the ends. Effectively what you are doing with low acceleration but high top speed is bridging between the curves with the previous layer providing support for the straight runs till it sets.

With a more advanced slicer with different acceleration/speed limits for curves and straight it should be possible to really up the speed/acceleration to the max on the straight runs.

Regards,

Martin

Martin Wolfe

Re: Does someone want to know how fast they can print/extrude? look here

...why does it collapse inwards like that?

Here's my mental model of it, which might explain it. As the extrusion cools, it creates tension. i.e. it resembles an elastic string connected to the nozzle. If there's not enough fusing to counteract that tension, then it delaminates and creates a straight line between the nozzle and wherever it then is adequately fused. Thus, the problem shows itself first at the corners. Why? Well, if that elastic string delaminated when the nozzle has been travelling along a straight line, with the elastic string already adequately fused somewhere earlier along that same line, where is the elastic string going to go? Nowhere. However, on a corner, it's getting tugged from the side, so if it delaminates there, it quickly becomes obvious because of the above elastic string effect.

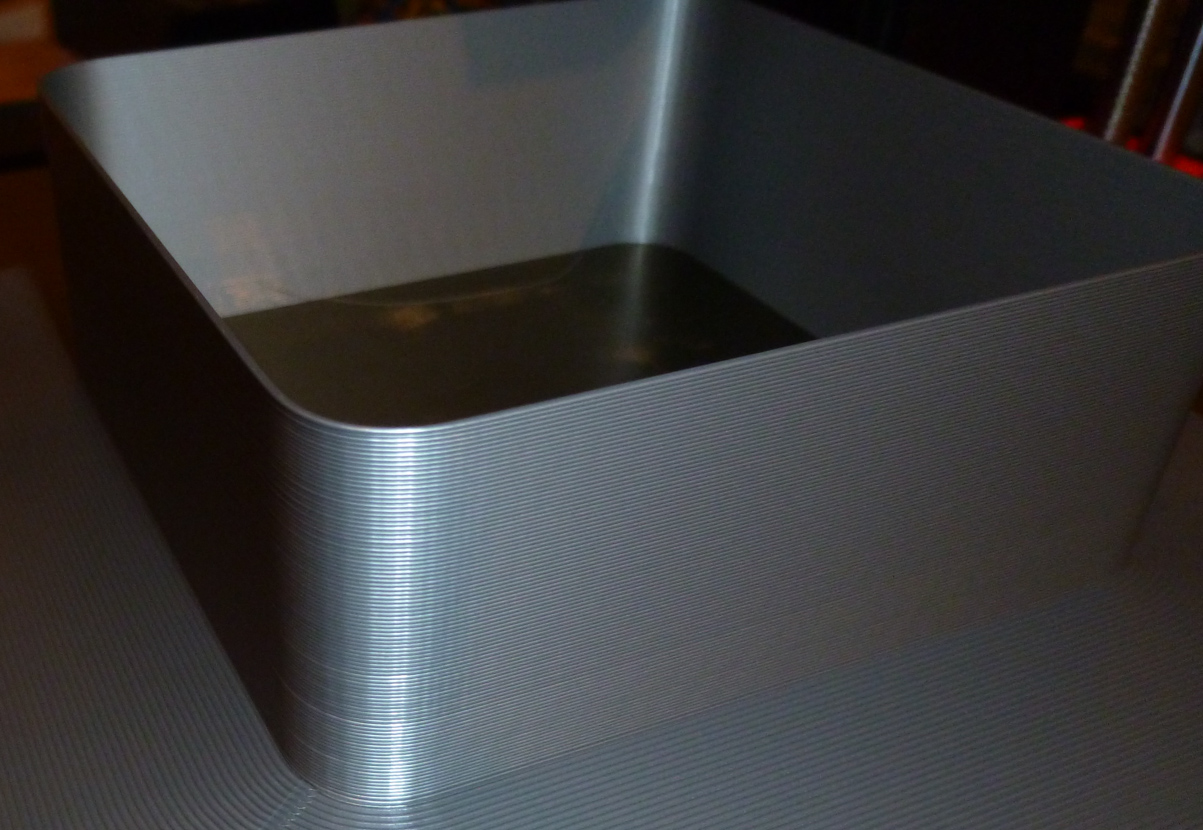

Now, the good news is that if I reduce xy acceleration to 20 (i.e. M201 X20 Y20), it all hangs together even at the corners, and without any meaningful artificating.:

The bad news is that the artificating is already clearly visible with acceleration as low as 30:

-

Either way, it can print like that forever, because the low acceleration puts a limit on the top speed that the print-head can attain. In other words, it defeats the test, because the test is supposed to be testing at ever increasing speeds, which can't happen when acceleration is so limited. Of course, at even higher acceleration there's eventually complete failure, as you've already seen in the earlier photos.

When I began this, I didn't expect to find such a strange result. 😯

Re: Does someone want to know how fast they can print/extrude? look here

Just to see, I added linear advance (K=20) to DevilHunter's test but kept the same previously artificating acceleration at 30. I let DevilHunter's test run to completion. I thought maybe the linear advance would solve the artifcating, but it didn't:

In particular, the corner which developed artifacting eventually had it disappear as the test continued!

Well, that's hard to fathom!

I'm out of ideas at this point, other than maybe trying different layer heights or trying different nozzle diameters to see if either will make any difference. However, that seems like just random experimentation with no real theory driving it.

Re: Does someone want to know how fast they can print/extrude? look here

Just to see, I added linear advance (K=20) to DevilHunter's test but kept the same previously artificating acceleration at 30. I let DevilHunter's test run to completion. I thought maybe the linear advance would solve the artifcating, but it didn't:

Well, that's hard to fathom!

I'm out of ideas at this point, other than maybe trying different layer heights or trying different nozzle diameters to see if either will make any difference. However, that seems like just random experimentation with no real theory driving it.

Well this test is pointless to pursue to the end if the acceleration and speed values don't stay the same for M201 and M203

As said, at a certain point you are limited by the firmware or movement hardware, and you can hear that from the motor whining.

This test could show different things:

- You should stop printing if the last 5mm sounded exactly the same - > go to firmware and increase speed for M201 and M203

- Increase cooling via additional/different fans if the layers sag

- Increase Hotend or Extruder capability if your machine can move faster but is limited by plastic flow

It's not possible to print this thing to the end if all parameters are unlocked, plastic flow or acceleration will hit a wall first.

Thanks for running the extrusion speed test, nobody else did.

I would be looking forwared if you get the chance to try a 0.4mm nozzle, for comparison.

Re: Does someone want to know how fast they can print/extrude? look here

@martin Do you think the copper volcano will be able to successfully print at higher speeds? I'm thinking maybe yes: if the filament comes out hotter, isn't it more likely to fuse to the layer beneath it? DevilHunter's estimate of just 5% improvement doesn't sound very motivating to me. How much would you estimate?

Re: Does someone want to know how fast they can print/extrude? look here

With a more advanced slicer with different acceleration/speed limits for curves and straight it should be possible to really up the speed/acceleration to the max on the straight runs.

^^^This

Are there any slicers that currently can do that?

Re: Does someone want to know how fast they can print/extrude? look here

David,

It is not a question of making the filament hotter. It just not cooling fast enough before the print head goas through a direction change. That is why the extra fan and low acceleration had an effect. It was setting those corners sonner so the changing direction of the print head would not pull the filament to the side. Also you are not the only noob here I got my MK3 in February and it was my first 3D printer.

The plated copper has three main effects. The most beneficial for the more common filaments is that it is more slippery meaning materials such as PETG are less likely to stick to it. The second is to withstand higher temperatures so that some of the more exotic filaments with a working temperature can be used. In the Volcano the higher conductivity is not going to have as much of an effect except for high temperature filaments as you are really being limited by the surface area of the nozzle that is in contact with the filament.

With regards to your question about slicers that could do what I suggested. As far as I know no such beast yet exists. That is why I called it advance. Up till now not many 3D printers have run into the limits that a Volcano fitted MK3 has.

Regards,

Martin

Martin Wolfe

Re: Does someone want to know how fast they can print/extrude? look here

The plated copper has three main effects. The most beneficial for the more common filaments is that it is more slippery meaning materials such as PETG are less likely to stick to it.

Well, in that case, maybe most of the benefit would come from just a copper nozzle? I mean, it abuts the heatbreak, and AFAIK the filament never touches the heating block.

Re: Does someone want to know how fast they can print/extrude? look here

E3D say in their literature on their website "Note: silicone socks are not intended for use at temperatures exceeding 300°C. Similarly, upgrade to a PT100 if you are printing at high temperatures."

As a result of this different method must be found to reduce the thermal gradient in the block and nozzle the method E3D chose was to use plated copper.

In an aluminium block with brass nozzle and sock the insulating properties of the sock keep the thermal gradient shallow so that the temperature at the nozzle to filament interface is close to the target temperature.

In a platted copper block and nozzle combination the higher conductivity of the copper keeps the gradient shallow as more heat energy can flow through the block for the same target temperature.

In both casses although with the plated copper more heat energy will need to be pumped in as more is lost to the surrounding air for the same temperature at the thermistor should result in the same temperature at the nozzle/filament interface.

Keeping a shallow thermal gradient in the block/nozzle combination is the primary reason why E3D recommend the use of the sock on the aluminium/brass combination and not on the copper one.

So if you are printing in the range 300-500C which an aluminium block can handle you would be better off using copper.

Regards,

Martin

Martin Wolfe

Re: Does someone want to know how fast they can print/extrude? look here

For me, two of the take-aways from this thread are:

1. I can print faster in PETG than in PLA. Who knew?

2. When modelling, avoid curved corners. Until advanced slicers arrive, it's better to have perpendicular corners if print speed is the goal. Prior to this thread, perpendicular corners is what I had been doing my testing on. The effects of the curved corners in DevilHunter's test illustrate the havoc.

Yesterday I ordered a 1.2mm volcano nozzle to try out. I suspect that for printing boxes, it may be hard to beat. As an aside, I ordered it from matterhackers, because they have free shipping and they're much cheaper than amazon. They're also, I believe, an official distributor for E3D, so hopefully it will be the real deal and not Chinesium.

Re: Does someone want to know how fast they can print/extrude? look here

I would be looking forwared if you get the chance to try a 0.4mm nozzle, for comparison.

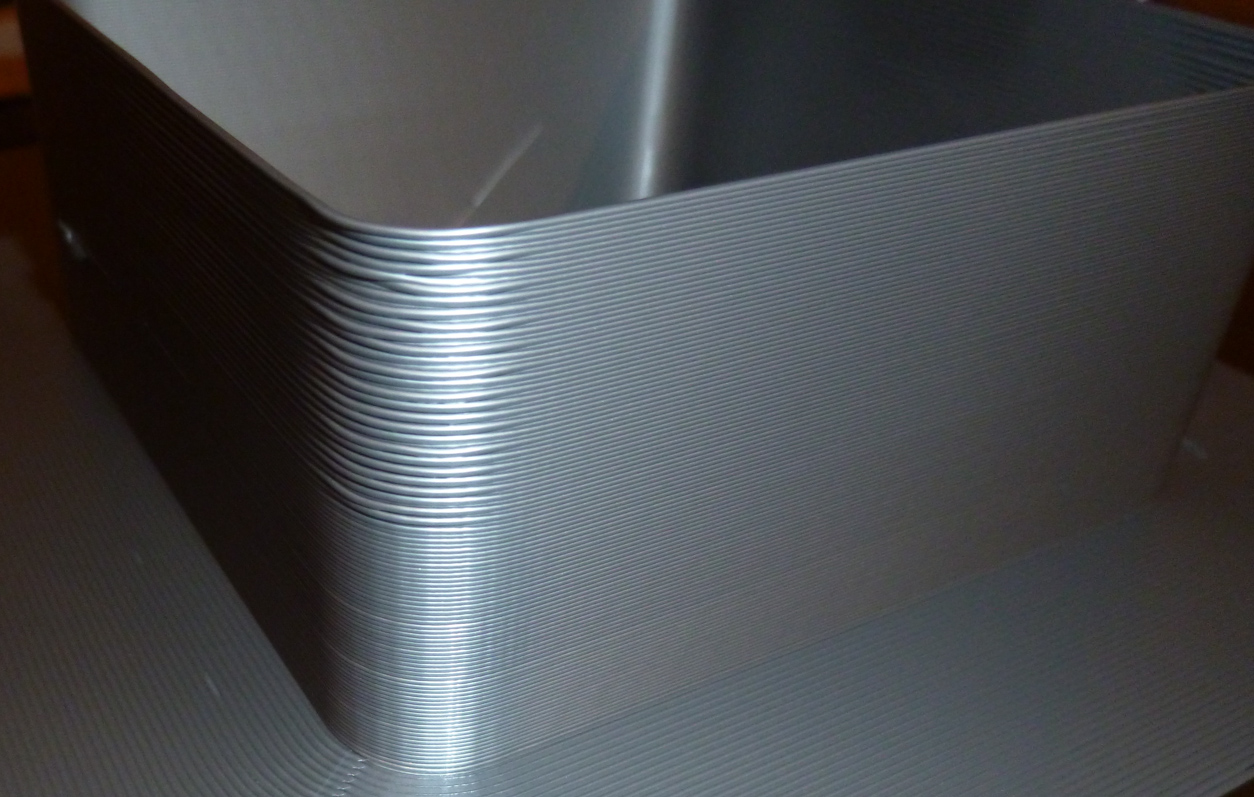

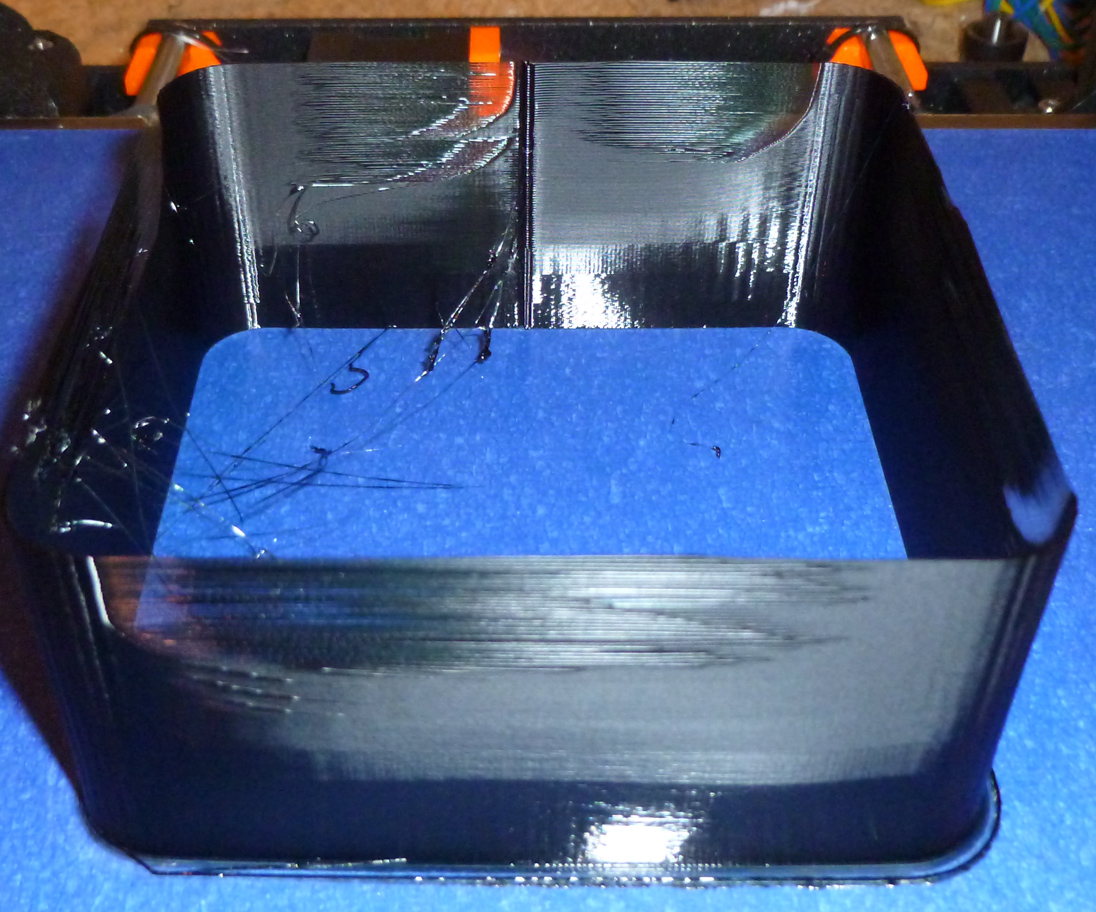

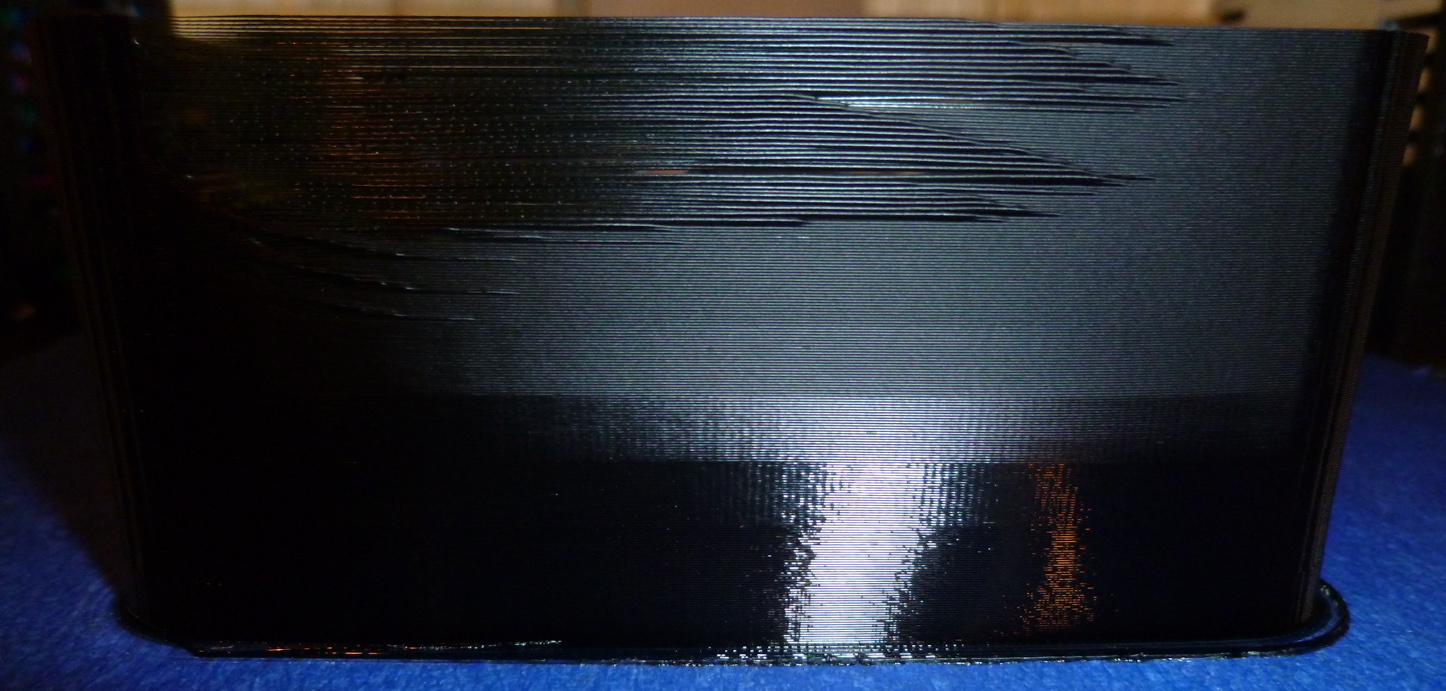

OK, here you go. Here's your test running a 0.4mm nozzle with PETG:

As you can see, it's mode of failure is remarkably consistent on all four sides.

Here's a closeup of the front:

I hope the above somehow helps you. It's interesting that, unlike the 0.8mm nozzle, it doesn't fail on the corners, but instead just after them. I wonder why that would be? Is it hitting the extrusion limit?

Re: Does someone want to know how fast they can print/extrude? look here

I wonder why that would be? Is it hitting the extrusion limit?

It certainly looks like it is. You can see the changes from the nice glossy finish expected of a good black PETG as it works up before finally failing. Personally I would not print any faster than it was just before the first transition.

Regards,

Martin

Martin Wolfe

Re: Does someone want to know how fast they can print/extrude? look here

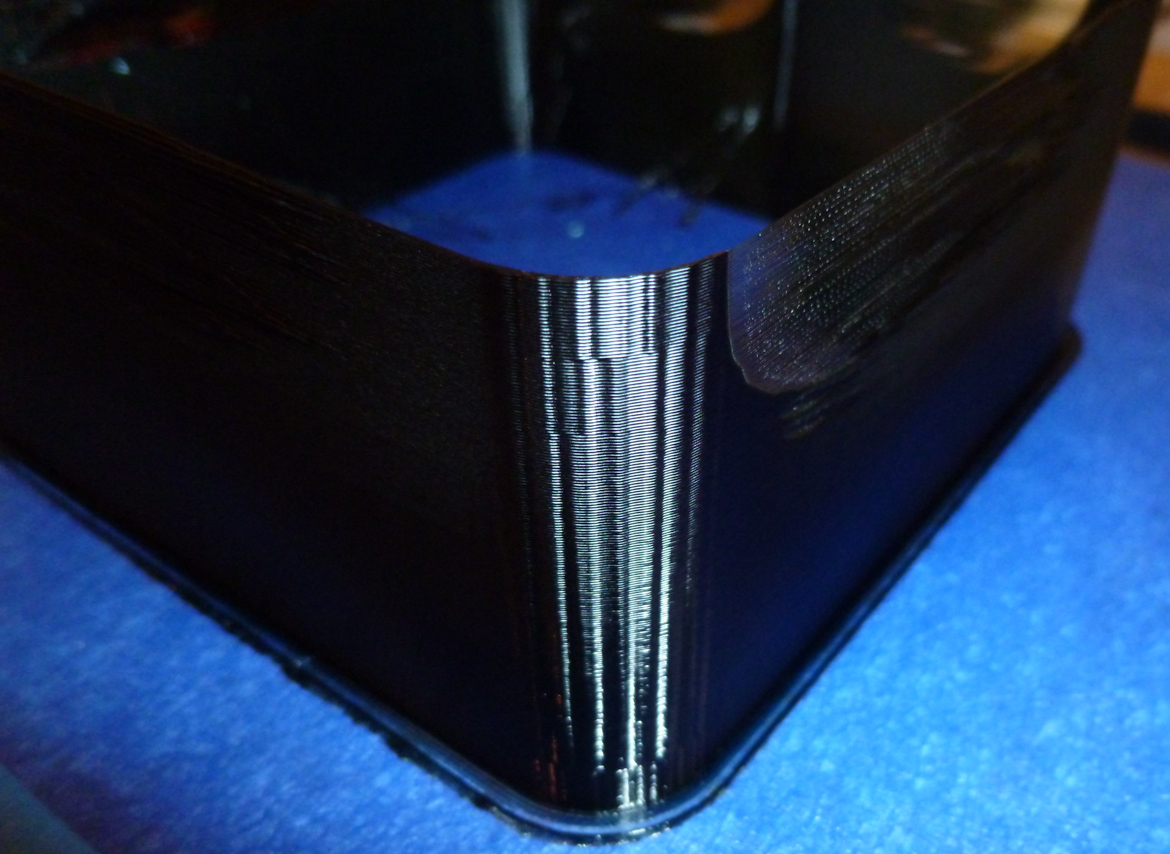

I think maybe it didn't fail on the corners because the narrower extrusion could cool more quickly. With the thicker 0.8mm extrusion, there just wasn't enough time before it got tugged aside.

With the 0.4mm nozzle, the corners were perfectly fine all the way to the top:

Re: Does someone want to know how fast they can print/extrude? look here

Personally I would not print any faster than it was just before the first transition.

Yes, I think you've persuaded me. Presumably the part strength should be higher when it's all one big glossy mass.

So, I guess this is it: 50mm/sec is all we can hope for? What speed is it without the volcano?

Re: Does someone want to know how fast they can print/extrude? look here

Increasing the K value may improve the results at the faster speeds with 0.4mm and PETG. This sort of under extrusion on the fast bits is exactly what linear advance was ment to fix.

Regards,

Martin

Martin Wolfe