Re: Does someone want to know how fast they can print/extrude? look here

Looks very nice. What kind of plastic is Greentec Pro? I tried looking at its datasheet ( https://www.extrudr.eu/filerpool/download/datei/84/ ) but there's no mention.

Re: Does someone want to know how fast they can print/extrude? look here

Not sure, I could not work it out from the data sheets although its chemical resistances seem similar to PLA. I still have to test it against acetone and ethyl acetate and run tests against high temperatures. However it is definitely more temperature resistant than HIPS. I also need to run a spring test on it to see how it recovers from high bending loads. To touch it feels similar to PLA and as I mentioned except for a lower nozzle temperature it prints like PLA.

Regards,

Martin

Martin Wolfe

Re: Does someone want to know how fast they can print/extrude? look here

According to the MSDS for Greentec Pro, it is "Biodegradable batch based on PLA, contains copolyester and additives."

Re: Does someone want to know how fast they can print/extrude? look here

Martin,

I'm not sure whether Prusa's blower speed control produces repeatable or even constant RPM's in its standard configuration. If so, that may be a complicating factor. However, I do know for sure that it doesn't produces repeatable or even constant RPM's if I increase the PWM frequency using the firmware setting which allows that, because I've measured it using an infrared tachometer. And that's while the printhead is standing still and not even moving. 🙄

Re: Does someone want to know how fast they can print/extrude? look here

Yeh. I get very inconsistant speed results when using the support/extruder option on the printer to read it. It is making tuning my fan nozzle a nightmare. Doesn't help that the ambient temperature near the printer is ranging from 27C to 31C due to the heat wave. If I can't get this thing tuned in the next couple of iterations I will be giving up. I thought it would be a simple process energy into the fan via PWM = Energy out via air pressure and velocity + losses due to inefficiencies. Not this highly incognisant speed/pressure I am getting. It is amazing that the original Prusa nozzle worked as well as it did.

Regards,

Martin

Martin Wolfe

Re: Does someone want to know how fast they can print/extrude? look here

Looks as though we can already buy volcano nozzles with a higher lubricity coating, such as the duraplat3-d:

https://filaments.ca/products/e3d-volcano-hercules-a2-tool-steel-hardened-nozzle

The Apollo series (see the chart) also claims a higher heat transfer ratio than brass.

Re: Does someone want to know how fast they can print/extrude? look here

The P3-D site in the Hercules goes down to 0.2mm. So no changing blocks for high detail prints.

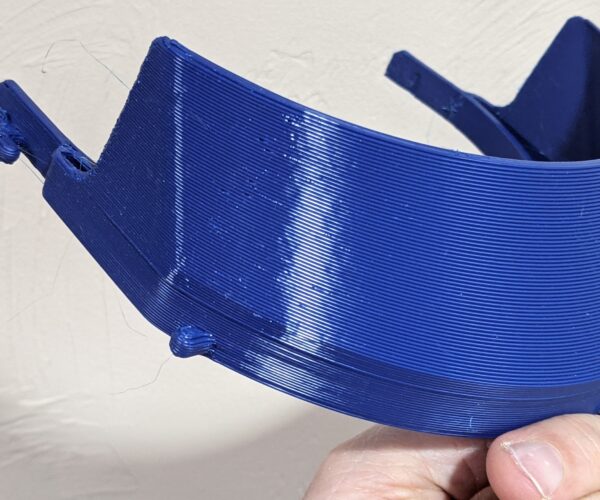

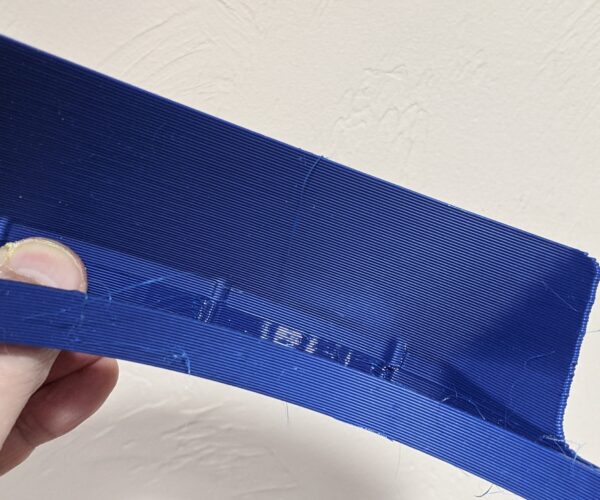

In Greentec Pro I managed to get decent prints out of the new Prusa print fan nozzle design. My nozzle design is no real improvement and does not meet my main design criteria of being model direction insensitive. However I will upload it and an updated volcano adaptor for the angled Prusa one this weekend.

Regards,

Martin

Martin Wolfe

Re: Does someone want to know how fast they can print/extrude? look here

The P3-D site in the Hercules goes down to 0.2mm. So no changing blocks for high detail prints.

Good point. And the smaller nozzle diameters would also be those for which you would most want the higher lubricity, so this might be the best choice for small diameter volcano nozzles.

Re: Does someone want to know how fast they can print/extrude? look here

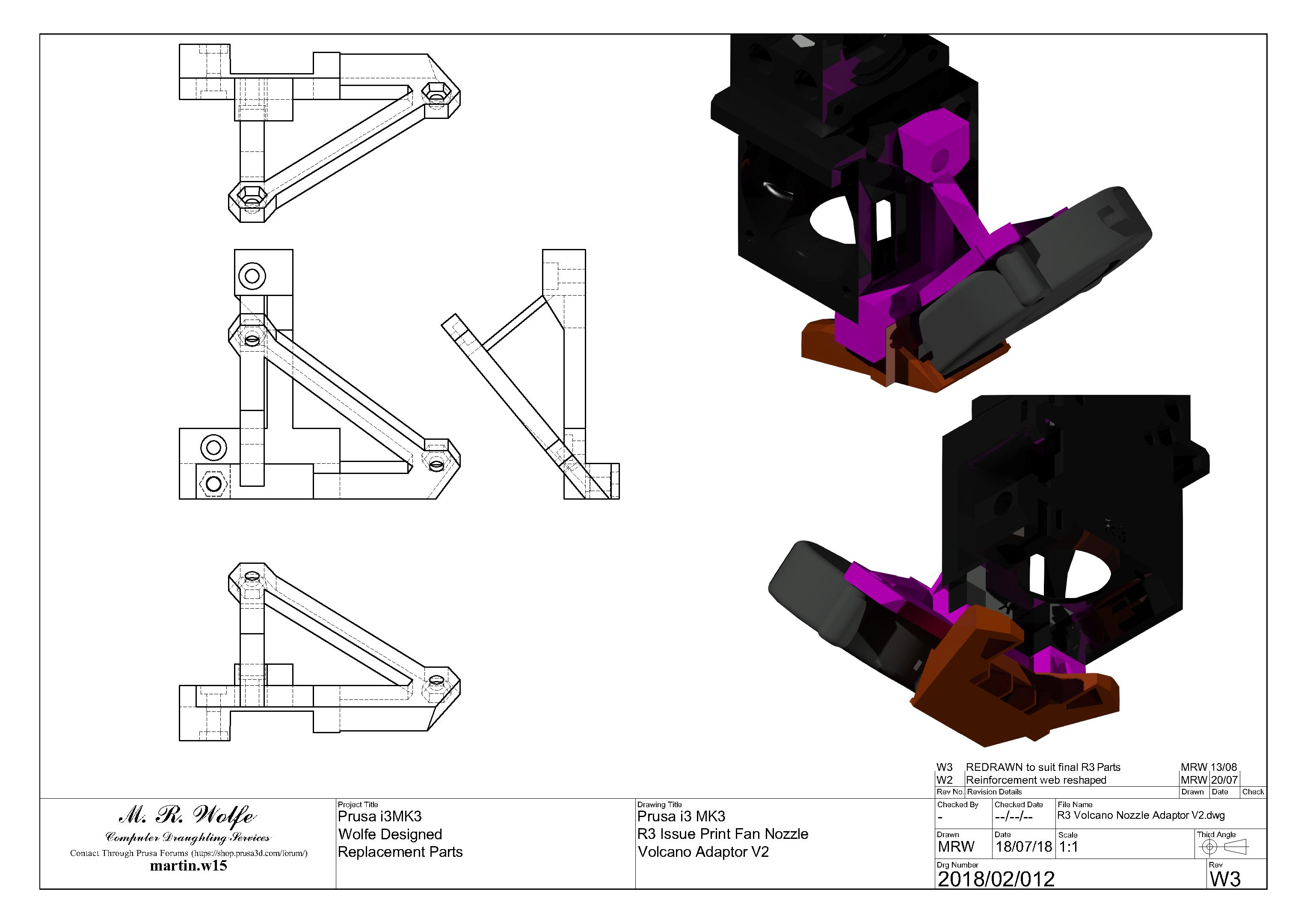

I have uploaded version 2 of my Volcano adaptor for the R3 parts to Thingiverse.

R3 Volcano Adaptor V2 on Thingiverse

Regards,

Martin

Martin Wolfe

Re: Does someone want to know how fast they can print/extrude? look here

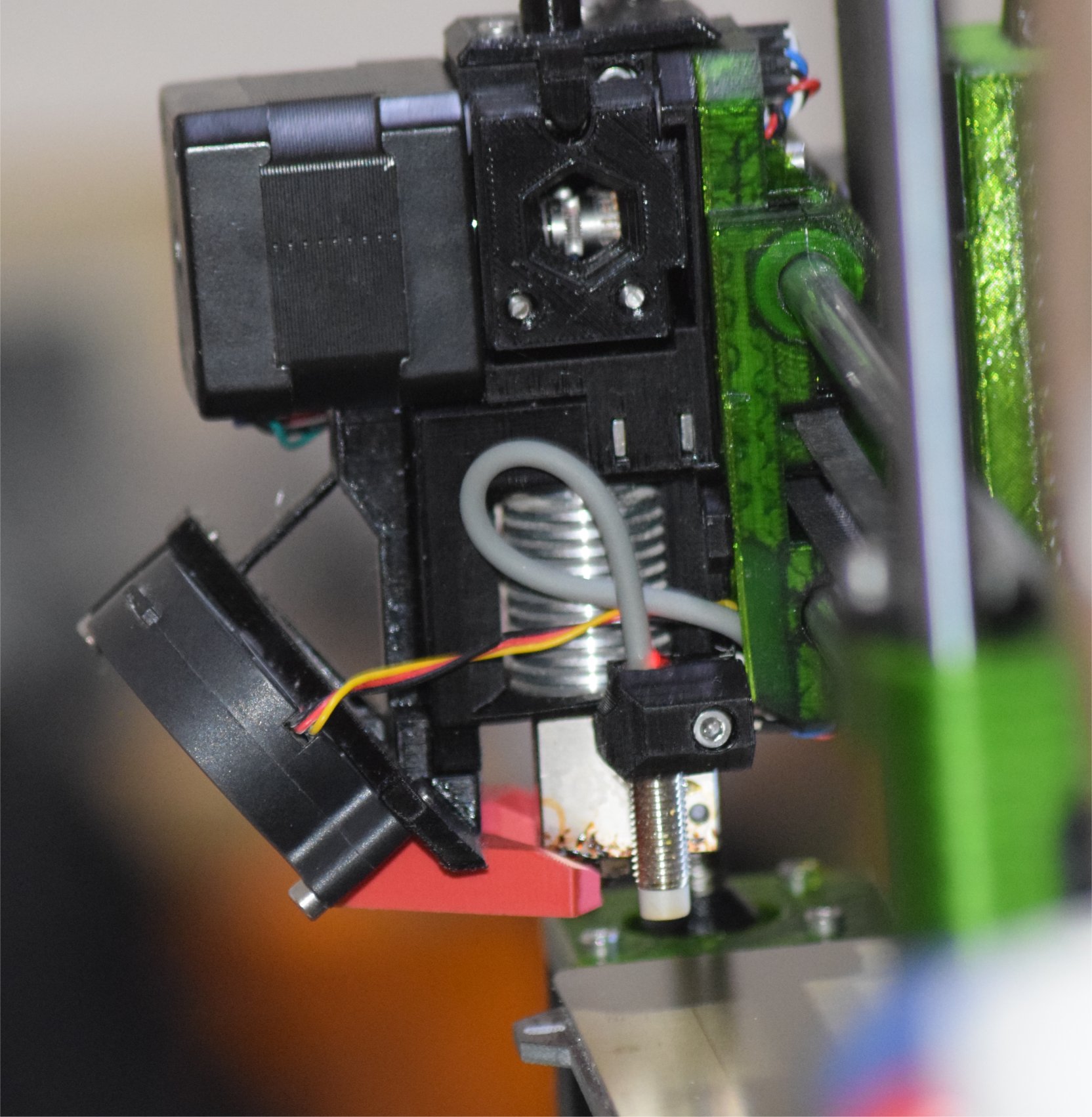

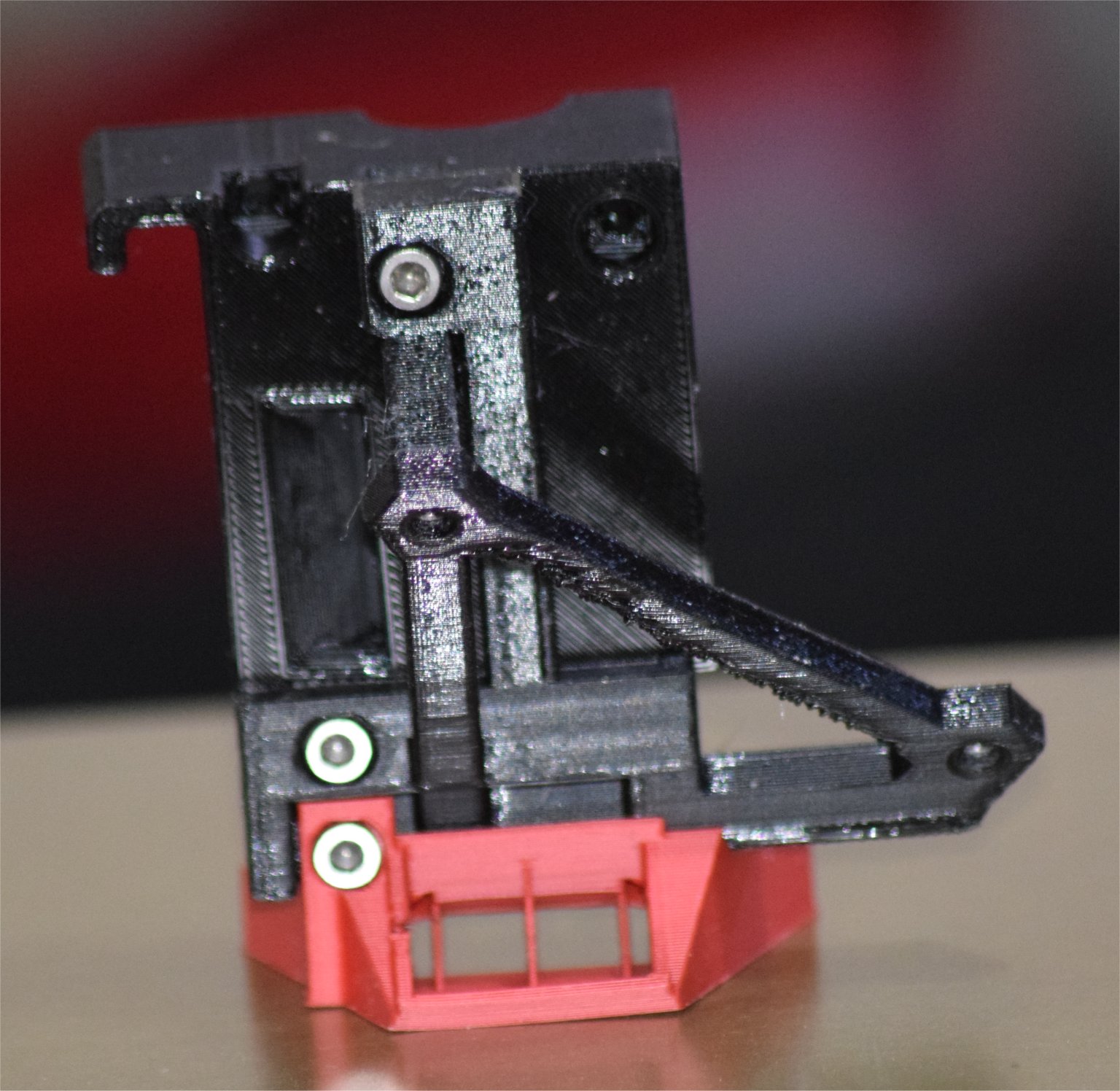

If any one is interested in trying it out here is my Volcano print fan nozzle. If you are using the final issue of the R3 extruder cover it is only held on by two screws and you will need a spanner to hold the third nut when fitting the fan.

Includes STL and DWG

I will not be publishing this on Thingiverse as it does not meet my design criteria and it is no longer fitted to my printer as I am using the R3 print fan nozzle with my adaptor as detailed in my previous post and found on Thingiverse.

Regards,

Martin

Martin Wolfe

Re: Does someone want to know how fast they can print/extrude? look here

Not sure if this is topical or not, but maybe: https://prusacommunity.com/to-the-moons-and-back/

Re: Does someone want to know how fast they can print/extrude? look here

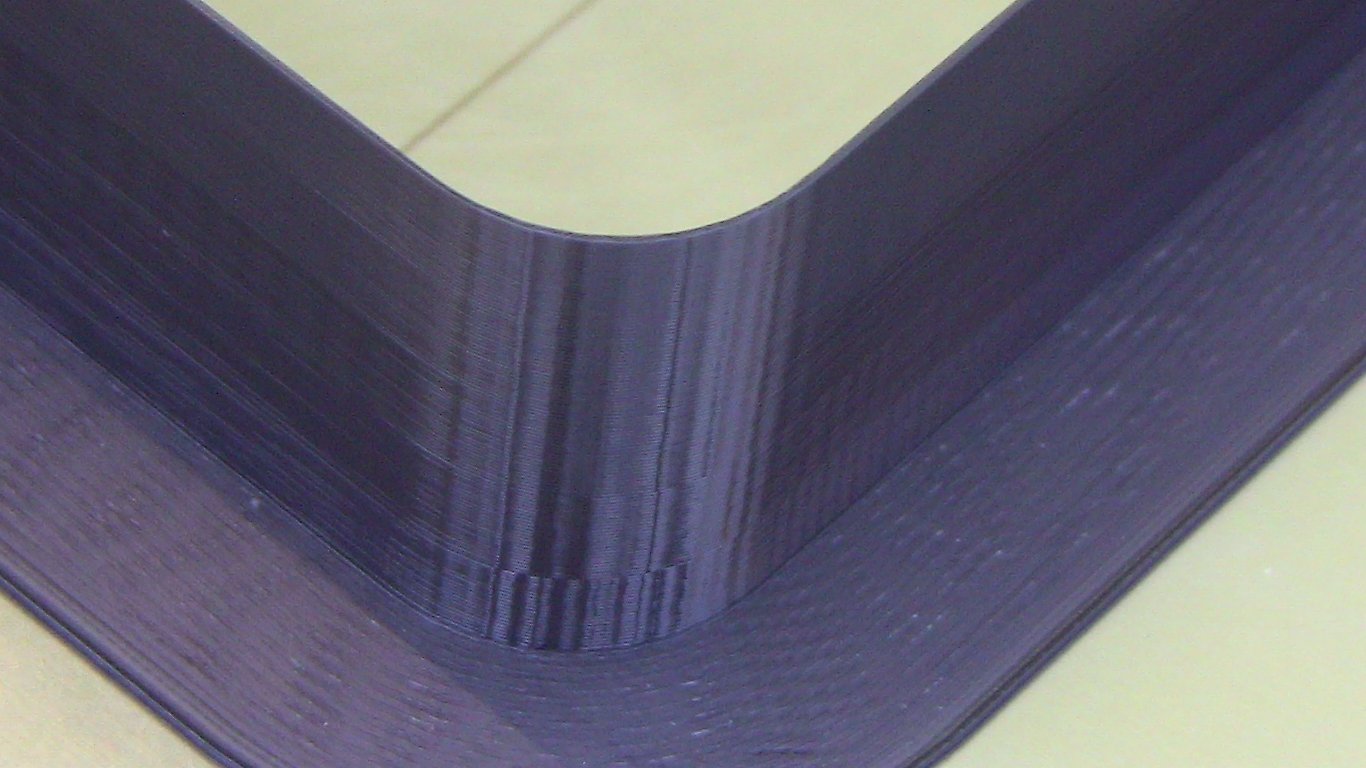

Included are the rounded cubes again with a 10mm brim, and one with Linear Advance on (Prusa stock K30), the other one with it off.

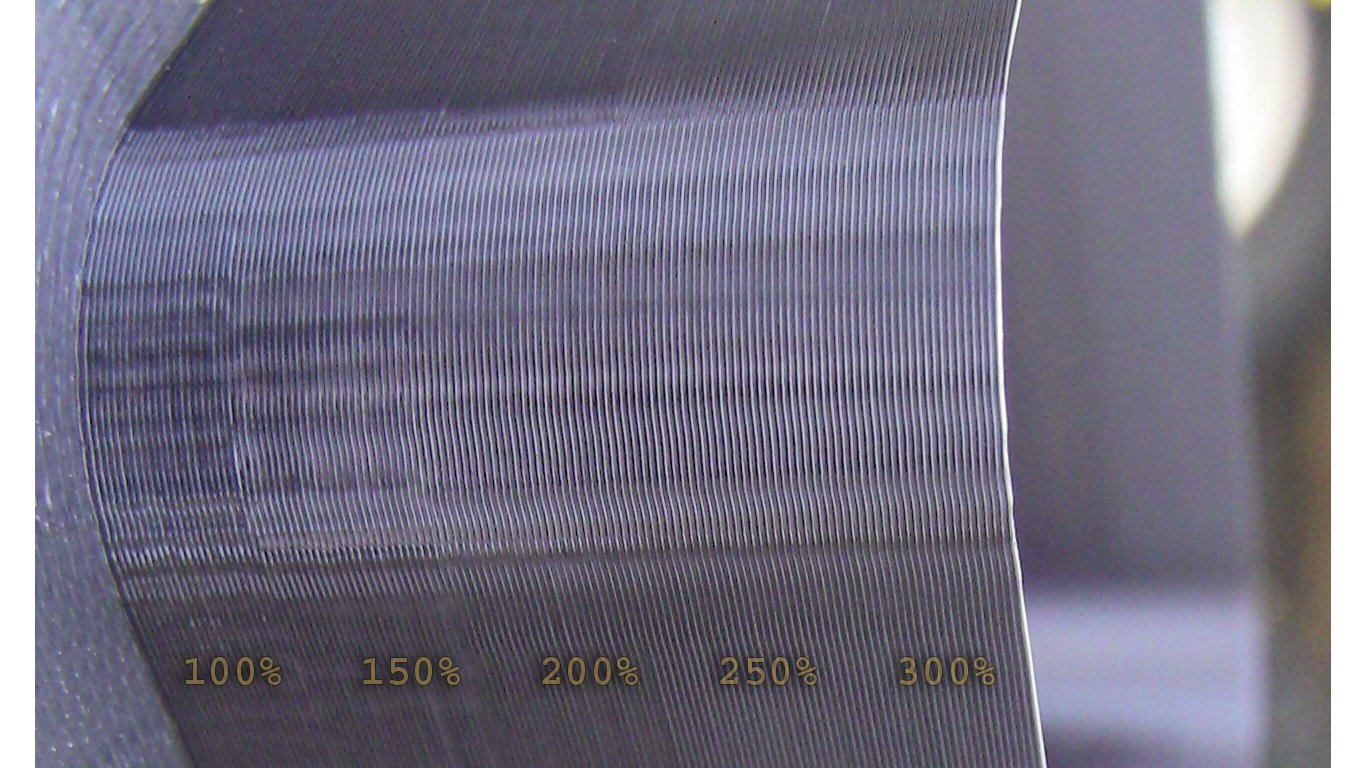

Here's my photo results (polarized), but I stopped it after it completed the 300% section (MK3 FW 33 final, PLA). I'm confused at why it keeps looking better the faster it got printed.

Re: Does someone want to know how fast they can print/extrude? look here

From my experience, the print speed depends on the material properties. The flow index is different among them, PLA>PETG>ABS. For some special pla material, like Ecoreprap 3d850 pla filament, the speeds are much slower than standard pla.

RE: Does someone want to know how fast they can print/extrude? look here

Does somebody want to know how fast they can move/extrude with their current setup?

I have put together a gcode for testing the speed you can get on your MK3 with the possible extrusion rate of your hotend.

It requires:

- Prusa MK3 or MK3 clone

- 0.4mm nozzle

- PLA filamentIt goes like this:

- 0.4mm nozzle

- 0.2mm layer height

- 1 perimeter, no top/bottom,infil

- 2mm brim for adhesion

- seam on back

- 50mm perimeter speed

- 230 degrees for PLA (with max fan setting)

- Layer change script for every 5mm in height.

- Linear Advance: OFFPrint object:

100x100x100 rounded test cubelooks like this

; gotta go fast

{if layer_z > 5 and layer_z < 6}M220 S150{endif}

{if layer_z > 10 and layer_z < 11}M220 S200{endif}

{if layer_z > 15 and layer_z < 16}M220 S250{endif}

...

and so on

What this does:

It changes the feed rate from 100% (50mm/sec) to 150% (75mm/sec) to 200% (100mm/sec) and so on for the print, meaning it will increase speed by 25mm/sec for every 5mm in printed layersYou should notice the following things:

- the motor speeds should sound different for every 5mm in layer height; the faster you go, the higher the whining of the motors.

If the motors don't sound different at the next 5mm in height, you are acceleration and feedrate locked by your firmware. (currently 1000 and 100 in the firmware) This speed script will go up 10-fold if possible. Changing the acceleration and feedrate in the firmware will let you print faster - provided your hotend is up to it.

- the extrusion rate of your hotend and the nozzle size will limit how fast you can print. If the layer lines will start to have holes in them, cancel the print immediately, you are done here. You cannot print any faster than that.I have holes at a feed rate of 600%, meaning 6 times x 50mm/sec, so 6x50 = 300mm/second possible print speed, but more like 250mm/s reliable print speed. (mainly because the temperature gets too cold to extrude, from the base 230 degrees, the faster it goes the less time the filament will get heated. layer lines look very cold at the top, will try to raise the temp on the next test.) Edit: nope, 250 degrees on PLA will not make it flow better.

My current setup for reference:

- E3D Volcano

- E3D 0.4mm Volcano Nozzle

- Prusa 40Watt heater @ 230 degrees

- custom built MK3s + custom firmware

- DasFilament black PLAThis gcode works on normal MK3's too.

Your Results will be:

100% speed OK = 50mm/s

150% speed OK = 75mm/s

200% speed OK = 100mm/s

250% speed OK = 125mm/s

300% speed OK = 150mm/s

350% speed OK = 175mm/s

400% speed OK = 200mm/s

450% speed OK = 225mm/s

500% speed OK = 250mm/s

550% speed OK = 275mm/s

600% speed OK = 300mm/s

650% speed OK = 325mm/s

700% speed OK = 350mm/s

750% speed OK = 375mm/s

800% speed OK = 400mm/s

850% speed OK = 425mm/s

900% speed OK = 450mm/s

950% speed OK = 475mm/s

999% speed OK = 499.9mm/sAttachments:

speed test_cube_0.4mm.gcode <- Print this

speed_test_cube.stl <- don't print this, just how it will look likeNote:

- i can do this for a 0.6mm or a 0.8mm nozzle, too, if you post screenshots of your usual print settings

(Screenshots of: Layers & Perimeters, Speed, Advanced)

- i take no responsibility if your Printer explodes 😉 (j/k, stock MK3's are locked down speed wise in the firmware)Again, the only way to check if you are actually going faster is to listen to the sound of the X/Y motors.

If it's not sounding different, you are locked speed wise in the firmware (I think stock MK3s are locked down to 200mm/s acceleration)change in configuration_prusa.h

#define DEFAULT_MAX_ACCELERATION {4000, 4000, 200, 5000} // (mm/sec^2) max acceleration (M201)

#define DEFAULT_MAX_FEEDRATE {500, 500, 12, 120} // (mm/sec) max feedrate (M203)

Hi there, Are the files still available for testing please

Prusa i3 MK2s MK2.5s Mk3 Mk3s BearPrusa Zaribo 320 - Kit Build - Rc Driver - Tweak freak...

“I know nothing about surpassing others. I only know how to outdo myself.†-Bushido-

RE: Does someone want to know how fast they can print/extrude? look here

Update to this thread: E3D has since released a 24v SuperVolcano. The upgrade kit costs about $100, and with its gigantic melt zone it should allow extruding with much larger nozzles as well as much faster print speeds. For the money, is it the ultimate hotend on the market?

Anyone here tried it on their Prusa or other 3D printer? I'm toying with the idea of mounting one on a dedicated "draft" printer, possibly a corexy as those seem to support the fastest kinematics. Is there a 3D printer that comes with it already installed? That would save the waste of buying a printer only to immediately upgrade it.

RE: Does someone want to know how fast they can print/extrude? look here

As detailed in the other thread, the Prusa extruder is going to limit how fast you can print with a basic Volcano. I found that simply replacing my nozzle with a 3D Solex Matchless type allowed filament to flow faster (with PETG) than the extruder could keep up with. Unless you replace the extruder, going with a much faster hotend won't gain you much. Also important to realize that different filaments print differently (see other thread linked above). A massive hotend and extruder that can push PETG at 70mm^3/s is still likely going to be limited to rates half that if your favorite filament is PLA.

Feel free to check out my data. It's not complete, but I've got a good sampling done with an E3D V6 hotend (Prusa Mk3) and Volcano clone (Artillery Sidewinder X1). The data was all gathered during the PPE storm, so my methodology is hardly perfect, but it gave me workable values.

tl;dr: Speed is an illusion. 300mm/s doesn't mean a thing. It's the amount of plastic you can move that matters.

Also worth noting, the Dragon hotend is a drop-in replacement for the E3D V6 and won't require hardware or firmware updates.

That original thread really got me started on thinking about all this, and was a real help when the PPE push came! Lots of good early research there.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Does someone want to know how fast they can print/extrude? look here

As detailed in the other thread, the Prusa extruder is going to limit how fast you can print with a basic Volcano. I found that simply replacing my nozzle with a 3D Solex Matchless type allowed filament to flow faster (with PETG) than the extruder could keep up with. Unless you replace the extruder, going with a much faster hotend won't gain you much. Also important to realize that different filaments print differently (see other thread linked above). A massive hotend and extruder that can push PETG at 70mm^3/s is still likely going to be limited to rates half that if your favorite filament is PLA.

Feel free to check out my data. It's not complete, but I've got a good sampling done with an E3D V6 hotend (Prusa Mk3) and Volcano clone (Artillery Sidewinder X1). The data was all gathered during the PPE storm, so my methodology is hardly perfect, but it gave me workable values.

tl;dr: Speed is an illusion. 300mm/s doesn't mean a thing. It's the amount of plastic you can move that matters.

Also worth noting, the Dragon hotend is a drop-in replacement for the E3D V6 and won't require hardware or firmware updates.

That original thread really got me started on thinking about all this, and was a real help when the PPE push came! Lots of good early research there.

Thanks for your post and the great information therein!

Condensing it down to the essential conclusions so I know what to buy as soon as possible:

1. It sounds as though those of us on this thread should have been using PETG instead of PLA for running the speed tests. Very good to know. I like the Prusament and the Sainsmart PETG because they both have 0.2mm tolerance and very nice windings. Have you found PETG that works even better for making faster prints?

2. Switching to Solex Matchless nozzles apparently helped quite a lot. Which nozzle size have you settled on for regular use? Your PPE article seems to imply 0.6mm.

3. You decided to stick with the regular V6 hotend that's standard with the Prusa I3 MK3/s/+ because you found that even with the matchless nozzle the limiting factor isn't the hotend but rather the extruder. Is that right?

RE: Does someone want to know how fast they can print/extrude? look here

BTW, I'm surprised to hear that the extruder is the bottleneck because stepper motors can be driven much much faster than what's typical. You can also use higher voltages for a snappier response. A priori I would have guessed that maybe the "plan ahead" portion of the firmware on the 8-bit atmega328p would have become the limiting factor at higher speeds before the extruder.

RE: Does someone want to know how fast they can print/extrude? look here

[...] 1. It sounds as though those of us on this thread should have been using PETG instead of PLA for running the speed tests. Very good to know. I like the Prusament and the Sainsmart PETG because they both have 0.2mm tolerance and very nice windings. Have you found PETG that works even better for making faster prints?

Maybe not PETG specifically, but PLA doesn't seem well suited to high speeds. It seems to have a non-Newtonian property that makes it not compress well with rapid pressure. At least that's the impression I have after trying multiple PLA types. Other co-polymers should work well. I have no idea about nylon and polycarbonate as I haven't done much with those yet. PETG at 250C moved very fluidly.

2. Switching to Solex Matchless nozzles apparently helped quite a lot. Which nozzle size have you settled on for regular use? Your PPE article seems to imply 0.6mm.

The 3D Solex Matchless nozzles have 2 channels drilled in from the top. The idea is that this maximizes the area of filament exposed to heat, speeding up the melting process. A cold pull (not easy to do) shows the internal geometry.

There was a small gain with the 0.4mm Matchless nozzle, but things really took off at 0.6 and 0.8mm sizes. With 0.6mm, I was able to move filament faster than the extruder could feed it, and print quality was better, so I stuck with 0.6mm for PPE. It will vary by print though.

Here's the visor we were asked to print here in Massachusetts. The tall visor made printing stacks impossible, so it was important to produce as many on the plate as possible. I was able to fit 3 on the Mk3 in a single print. Here's one of the rejects:

This was AmazonBasics PETG printed at 250C with 0.48mm layers at the bottom and 0.4mm layers for the sloping visor part with a maximum volumetric speed set to 32mm^3/s. I was able to print a plate of 3 visors in 3 hours, a 2-4X speedup over the normal profiles. I'd have to pull up the project to see what speeds I was hitting, but I recall 70mm/s with wide and tall extrusions. Even with that, the sloping visor printed well with no major stringing on the inside.

3. You decided to stick with the regular V6 hotend that's standard with the Prusa I3 MK3/s/+ because you found that even with the matchless nozzle the limiting factor isn't the hotend but rather the extruder. Is that right?

Exactly. The 3D Solex matchless design is a drop-in replacement for a V6 nozzle, so no firmware or other changes are required. Unfortunately, they don't produce a hardened version of the design. So long as you're OK with non-abrasive filament, you can just keep a Matchless nozzle mounted.

I do have a TriangleLab Dragon high-capacity drop-in which is a drop-in replacement for the V6, but I haven't had a reason to mount it yet. It's my standby if I ever need to push abrasive filaments at high speeds.

I would be curious to see what a Dragon+Matchless nozzle could push!

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Does someone want to know how fast they can print/extrude? look here

I would be curious to see what a Dragon+Matchless nozzle could push!

But if the bottleneck is the extruder, then... how would adding the Dragon help?

----------------------------

Bottom line: Do you recommend getting both the 0.6mm and 0.8mm matchless, or just the 0.6mm matchless?

Also, since, like me, you're in the US, where is a good place to order the matchless nozzles from?