Re: Does someone want to know how fast they can print/extrude? look here

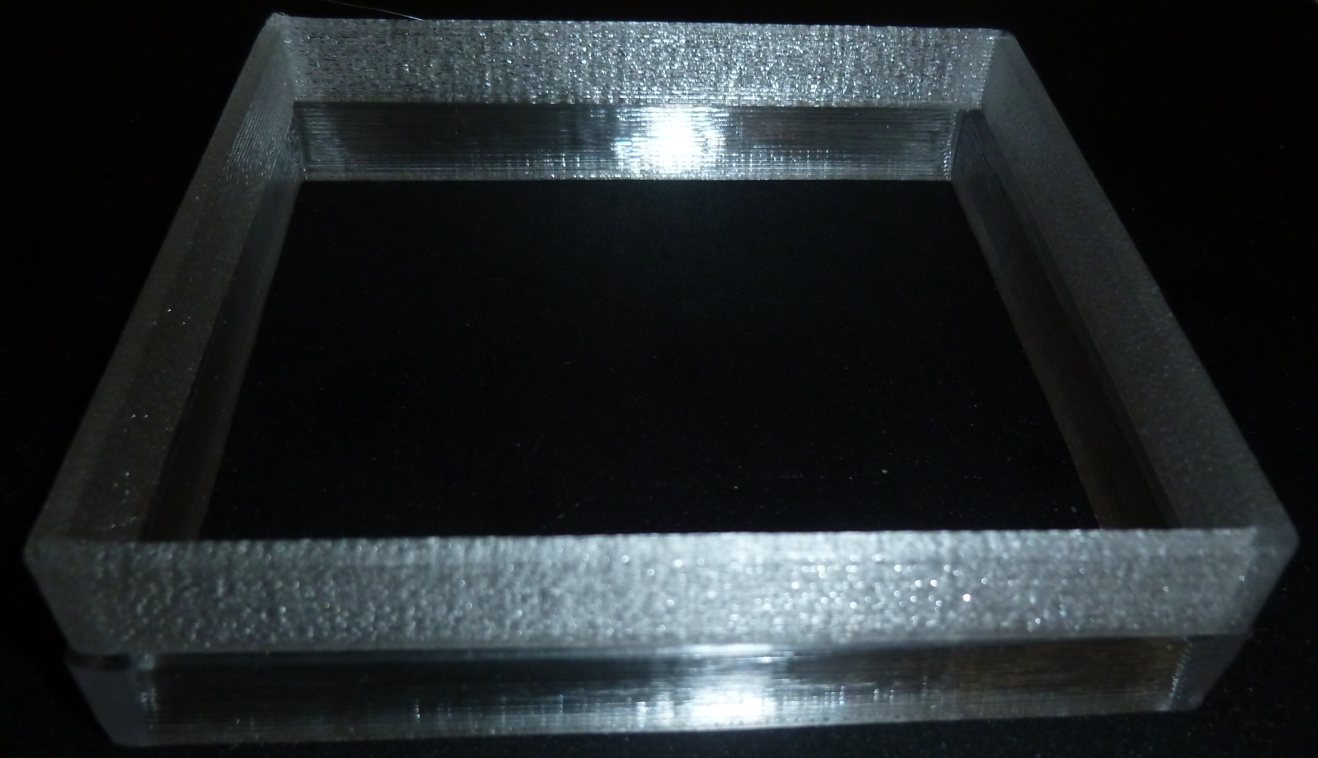

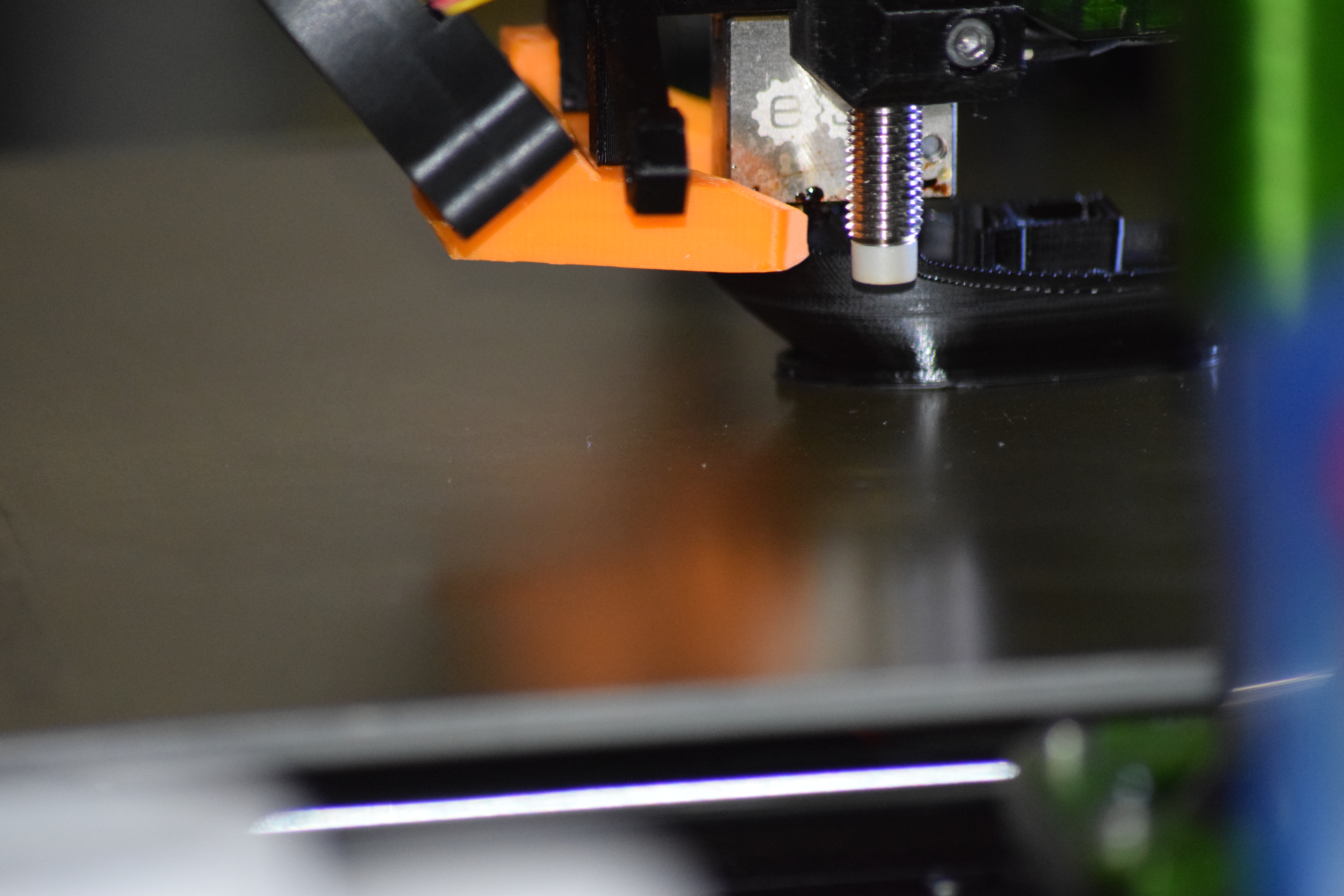

Surprising results. On the bottom is a 4.3mm wide extrusion, which looks fine and has a nice surface finish. On top of it is a 3mm wide extrusion, which doesn't look anywhere near as good:

The bad looking one is what the 2.7mm print looked like when I tried it earlier.

In both cases, layer height is 0.6mm. Both are single wall extrusions.

Re: Does someone want to know how fast they can print/extrude? look here

Surprising results. On the bottom is a 4.3mm wide extrusion, which looks fine and has a nice surface finish. On top of it is a 3mm wide extrusion, which doesn't look anywhere near as good:

compare_contrast.jpg

The bad looking one is what the 2.7mm print looked like when I tried it earlier.

In both cases, layer height is 0.6mm. Both are single wall extrusions.

They look like overheat or massive bubbles

Re: Does someone want to know how fast they can print/extrude? look here

Short of the megavolcano, I'm doubtful I can get much more speed out of this machine than what I'm already getting.

Re: Does someone want to know how fast they can print/extrude? look here

Just a small update. I have stopped iterating the design for now and going back on my last three iterations trying different print temperatures as I think I now have the nozzle the best I can. So it is just tuning to find which one is best. Once the best is selected I will use that as the basis for one with a separate fan protection/grill to sort out printing problems.

Regards,

Martin

Martin Wolfe

Re: Does someone want to know how fast they can print/extrude? look here

Inspired by the accidental discovery of getting good 4.3mm wide prints with the 1.2mm nozzle, I went back to my 0.4mm nozzle and find that I can get a perfectly good print at 1.2mm wide and 0.4mm layer height at 50mm/sec speeed. I consider that quite good progress! If my math is right, that translates into a volumetric extrusion of 32.5mm^3/second, which is far higher than I was able to get using a 0.4mm nozzle with more mainstream settings.

Re: Does someone want to know how fast they can print/extrude? look here

Inspired by the accidental discovery of getting good 4.3mm wide prints with the 1.2mm nozzle, I went back to my 0.4mm nozzle and find that I can get a perfectly good print at 1.2mm wide and 0.4mm layer height at 50mm/sec speeed. I consider that quite good progress! If my math is right, that translates into a volumetric extrusion of 32.5mm^3/second, which is far higher than I was able to get using a 0.4mm nozzle with more mainstream settings.

Math is wrong.

50*0,4*1,2 = 24mm/s^3

Never use nozzle size for first layer it need to squish a bit.

Also you should test that settings on a pratical print, do a benchy for example and see if it survive 😀

Re: Does someone want to know how fast they can print/extrude? look here

Ah, yes, you're right. Thank you for correcting me. Well, then, 24mm^3 is probably about the best my rig can do, which is better than what it could do before.

For these settings, I was thinking more for the scenario of simple project enclosures than for a benchie.

I don't believe there's anything more I can squeeze out of this machine.

Thanks everyone for your helpful comments along the way. 🙂

Re: Does someone want to know how fast they can print/extrude? look here

Ah, yes, you're right. Thank you for correcting me. Well, then, 24mm^3 is probably about the best my rig can do, which is better than what it could do before.

For these settings, I was thinking more for the scenario of simple project enclosures than for a benchie.

I don't believe there's anything more I can squeeze out of this machine.

Thanks everyone for your helpful comments along the way. 🙂

Try to squeeze that to 28mm/s^3 like mine do (PLA)

For enclosures it will do fine

Re: Does someone want to know how fast they can print/extrude? look here

Ah, yes, you're right. Thank you for correcting me. Well, then, 24mm^3 is probably about the best my rig can do, which is better than what it could do before.

For these settings, I was thinking more for the scenario of simple project enclosures than for a benchie.

I don't believe there's anything more I can squeeze out of this machine.

Thanks everyone for your helpful comments along the way. 🙂

Try to squeeze that to 28mm/s^3 like mine do (PLA)

For enclosures it will do fine

OK, I tried it at 28mm^3. Maybe because I'm using PETG, it's not quite able to extrude fast enough at that speed, and so there's some measurable impairment. e.g. walls are 1.1mm wide instead of 1.2mm wide that they're supposed to be.

Re: Does someone want to know how fast they can print/extrude? look here

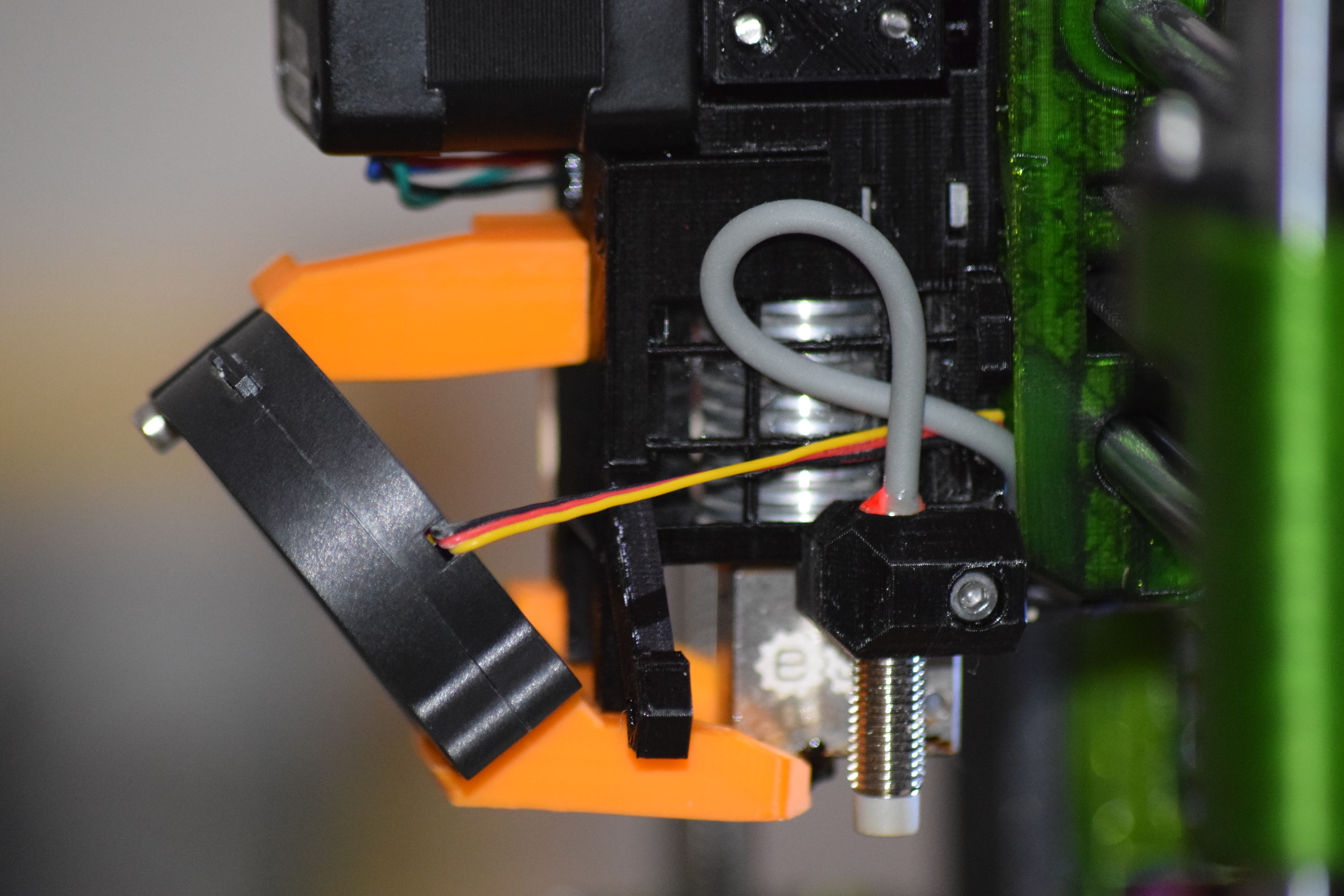

Prusa released "better cooling and extruder upgrade": https://www.prusaprinters.org/prusa-research-summer-update-2018/#cooling

Looks as though the upgraded cooler ducting will still blow some onto the hot-end but less than before.

Re: Does someone want to know how fast they can print/extrude? look here

Yup I saw. The second my current iteration is finished I'll take a look at it. With a bit of luck all my effort is now wasted. 😛 If not I will integrate what improvements I can take from it.

Regards,

Martin

Martin Wolfe

Re: Does someone want to know how fast they can print/extrude? look here

Well, yours works for the volcano. His will need some adapting.

Re: Does someone want to know how fast they can print/extrude? look here

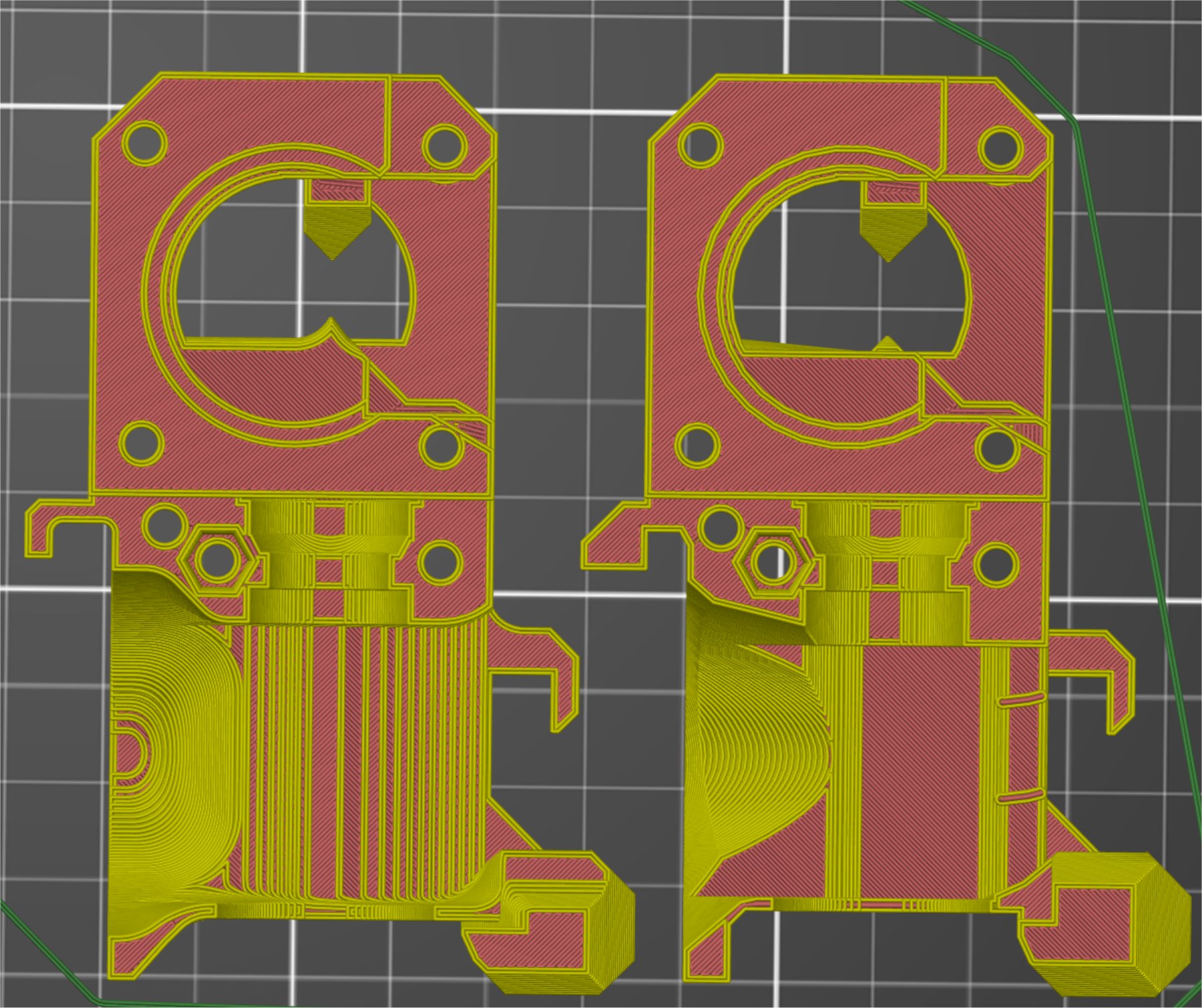

Yeh it will. There are more changes than the part nozzle though. The part nozzle looks like it will be an improvement over the R1/R2 version but how good it would be I don't know without testing. Still with the R2 Volcano universal extruder cover that is my W1 extruder cover I will be able to test the part cooling on a volcano with that print fan nozzle. Of more interest is the changes in the extruder. It looks more flex friendly but I will have to make minor changes to my nozzle to use it on the R3 extruder cover. Sill On the extruder and heat sink cooling side of things it looks to be a major improvement. I have put a comment on GitHub requesting the STLs so we can mod for Volcano compatibility.

R3 Left R2 Right

Regards,

Martin

Martin Wolfe

Re: Does someone want to know how fast they can print/extrude? look here

Well with regards to the W15 iteration of my nozzle it looks like I am almost there.

However I will test the R3 nozzle fitted to the W1Extruder cover/ R2 Extruder Body before going further. I still think that in the end my design will be better but the R3 will be a definite improvement.

Regards,

Martin

Martin Wolfe

Re: Does someone want to know how fast they can print/extrude? look here

I guess the Prusa upgrade uses two support pieces, one for each side of the fan? Otherwise, I don't see how it will fit together.

Re: Does someone want to know how fast they can print/extrude? look here

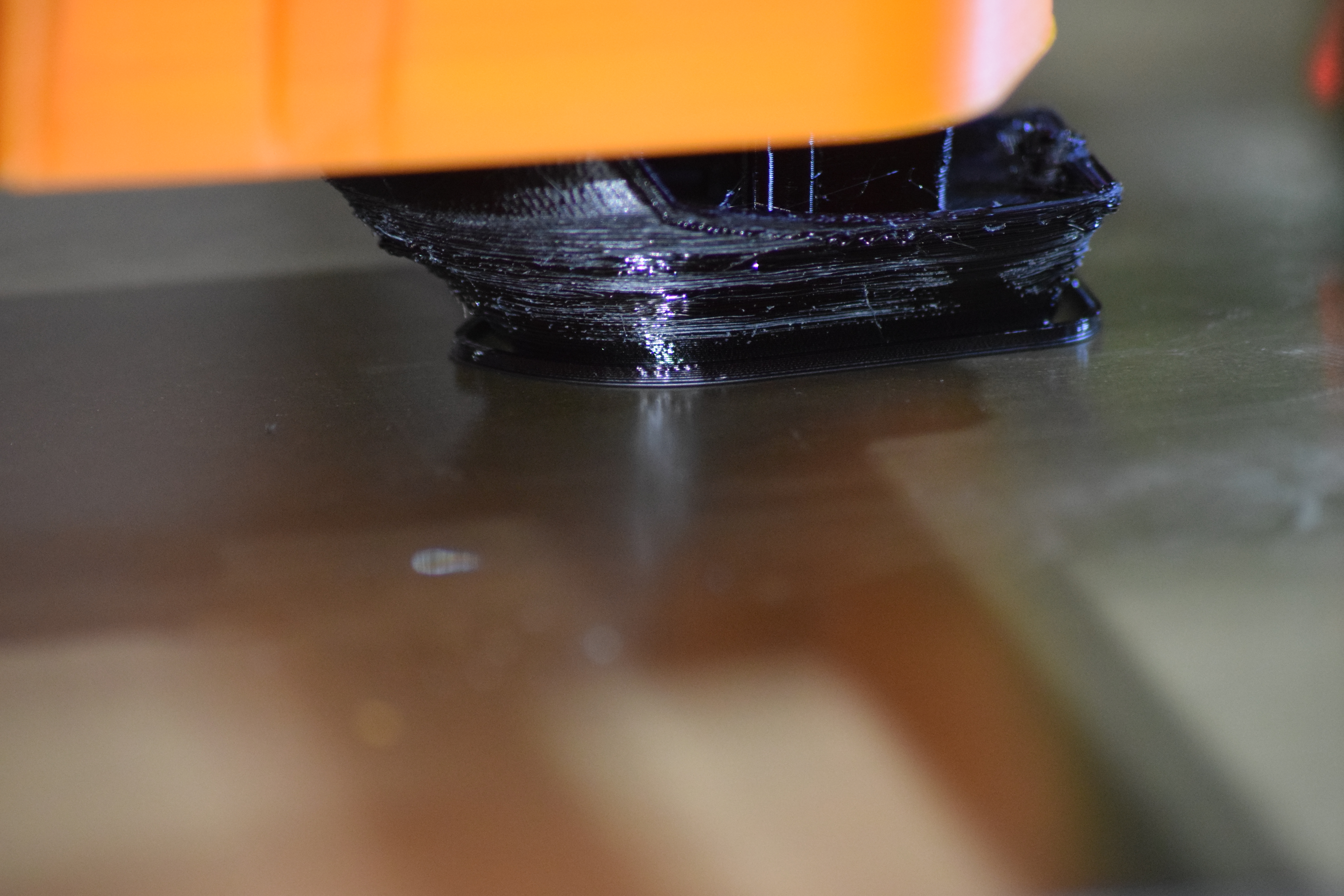

New R3 Nozzle Fitted to The Volcano Adapter Extruder Cover

Benchy Tests Left 220/230°C right 220/220°C

For some reason bed adhesion failed on the 220/230°C print and it got stuck on the nozzle. This print has a band is very slight over cooling and with a slightly over cooled bow shock.

The 220/220°C print I ment to select the 220/240°C file but printed the 220/220°C by mistake. Definite over cooling and an unacceptable bow shock.

Overall on the plated copper Volcano block and nozzle without sock this is a major improvement over the results I got from the R1/R2 nozzle which had a major bow shock at the ideal filament print temperature. At 220/235 it will likely give an ideal print with the Benchy facing front and the banding indicates that this may be the case with the Benchy facing an direction. If this nozzle had been around when I first fitted the Volcanno to my machine I doubt if I would have designed my own as its slight overcooling can be compensated for leaving the only problem being a need to redress the part fan lead. As my design is so close to completion I will finish it.

Regards,

Martin

Martin Wolfe

Re: Does someone want to know how fast they can print/extrude? look here

Thanks for the photos, Martin. That clarified for me how Prusa's upgrade fits together.

As a short-term option, I was able to attach the upgraded Prusa fan-nozzle combo just fine to the JLTX volcano extruder cover for the MK3 that I had previously installed and have been using. Of course, this doesn't have the benefit of the upgraded extruder heatsink air flow in Prusa's latest extruder cover design, but as a stopgap I can make do with it until either JLTX updates his volcano adapter or Martin finishes his volcano design.

Re: Does someone want to know how fast they can print/extrude? look here

I have found out why the 220/230C Benchy can away from the bed when I was testing the Prusa R3 print fan nozzle. It's a show stopper. It was causing the part to cool down far to much due to excess air blowing over it causing warping. This became painfully painfully obvious 2hours into the print for my W16 iteration when it can way from the bed.

Regards,

Martin

Martin Wolfe

Re: Does someone want to know how fast they can print/extrude? look here

Does the warping still happen at reduced fan speed?

Re: Does someone want to know how fast they can print/extrude? look here

No idea. I have removed the R3 nozzle for now. I will experiment with it more later at different fan speeds.

Regards,

Martin

Martin Wolfe