Re: Does someone want to know how fast they can print/extrude? look here

Martin i can't wait for the release, that look awesome, i also have problems with ducts i use, they fall, one screw is not good for hold that kind on part near a heat zone. Also i like the pinda protection, which will cooldown pinda with fan, like it!

Re: Does someone want to know how fast they can print/extrude? look here

Unfortunately, the promised Part 4 covering tests & analysis doesn't seem to have been written.

Yes, it's a bit damning I'm afraid. I can't help but think that if they had good test results, they would have posted them.

Meanwhile, curiosity got the better of me, and I ordered the so-called 400mm/sec PLA whose link I posted above, despite my general denouncement of PLA. Well, if anything can print that fast, I'd like to see it first hand!

Re: Does someone want to know how fast they can print/extrude? look here

Ah nice! Please post results. I'm very curious about this.

[...] Meanwhile, curiosity got the better of me, and I ordered the so-called 400mm/sec PLA whose link I posted above, despite my general denouncement of PLA. Well, if anything can print that fast, I'd like to see it first hand!

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

Re: Does someone want to know how fast they can print/extrude? look here

The Benchy print from the W4 iteration has now finished.

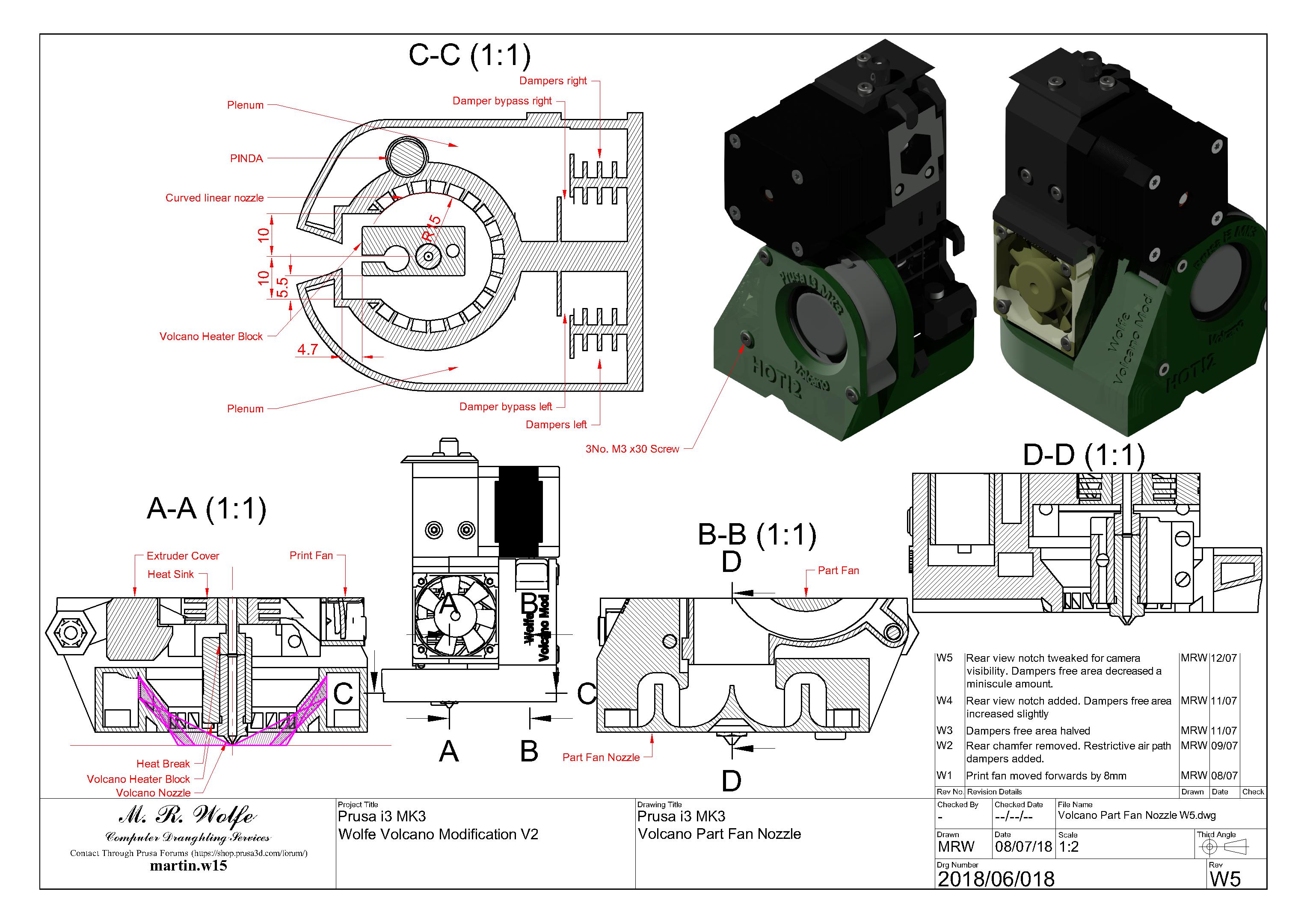

Both Benchys were printed with the plated copper Volcano heater block and nozzle. The left is with the default print fan nozzle and the right with the W4 iteration of my nozzle. The print setting Were identical.

Overall it is showing over cooling but very close. As I will have to go to iteration 5 for the rear camera and manual view cut-out tweak I will also tweak the dampers very slightly to increase their resistance.

The melting problem seems to have been solved.

It was only a two hour eighteen minute print but even the fine print faults and sharp edges were all still unaffected.

Tiago the PINDA protection is not for cooling the PINDA. It is just the PINDA was in the way of getting decent the air flow to the rear right corner of the print. With regards to the single screw on the default nozzle I agree with you. So I made use of the fan mounting points. The result beng is that it requires 3no. M3 x 30 screws to fit it.

Regards,

Martin

Martin Wolfe

Re: Does someone want to know how fast they can print/extrude? look here

Sorry for the noob question, but In a nutshell: how can you tell when a part is being overcooled or undercooled? What are the indicators?

Re: Does someone want to know how fast they can print/extrude? look here

Over-cooled will tend to be brittle with poor layer adhesion. Under-cooled will tend to droop or look melted, particularly on overhangs and bridges. I'm sure there are more precise descriptions, but that's how I judge it.

Sorry for the noob question, but In a nutshell: how can you tell when a part is being overcooled or undercooled? What are the indicators?

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

Re: Does someone want to know how fast they can print/extrude? look here

For black PETG it is relatively easy to tell. That is why I am using it in my test prints. The ideal part should be nice and glossy with all the filament in place and ideally minimal stringing. Too hot gives a saggy mess and too cold goes matt possibly even grey and the filament does not bond properly.

The effects too cold can be seen in the rough grey bow shock on the default print fan nozzle print and too a lesser extent on the W4 iteration print. The same goes on the lack of gloss on parts of the two prints.

An Under Cooled Benchy From W3 the Iteration

I am trying to tweak the design so that it will give best results with the default Prusa cooling fan profiles.

Regards,

Martin

Martin Wolfe

Re: Does someone want to know how fast they can print/extrude? look here

Martin i thought the pinda was in the air duct, i was wrong. I used a shroud sometime ago that also have a pinda hole but that stay on a air duct, i find it very usefull since i like to start all my prints at 35ºc, easy to cooldown pinda when you have multiple prints, just turn on the fan and see temp drop 😀

About fan holes the single hole from stock is ok when you install it first time, but after many replacements hole got wider and it will not hold like before. Make use of part fan screw holes is that prusa and other makes should use.

This is what we need 😀 3x the std volcano volumetric speed (+/- 90mm/s^3)

Re: Does someone want to know how fast they can print/extrude? look here

Not sure that the Mega Volcano would be useful on a Prusa i3 MK3 it would loose a fair bit of print height. Still if you go to the Full Bear Mod and turn the X-Ends upside down you could get full build volume with it.

The Mega Volcano is really intended for large print volume printers such a core X-Y, Ultimaker clone or similar design. As with a large print volume the basic I3 design moving the printed part in the Y direction will cause all sorts of problems due to the mass of the printed part.

Regards,

Martin

Martin Wolfe

Re: Does someone want to know how fast they can print/extrude? look here

Not sure that the Mega Volcano would be useful on a Prusa i3 MK3 it would loose a fair bit of print height. Still if you go to the Full Bear Mod and turn the X-Ends upside down you could get full build volume with it.

The Mega Volcano is really intended for large print volume printers such a core X-Y, Ultimaker clone or similar design. As with a large print volume the basic I3 design moving the printed part in the Y direction will cause all sorts of problems due to the mass of the printed part.

Regards,

Martin

yes, is overkill. With custom bear mod you can put larger rods and larger everything to go up, even at 400mm if you extend cables.

CR 10S5 should take profit of this, Also good for delta

Re: Does someone want to know how fast they can print/extrude? look here

You are going fast with the development 😀

My volcano block is not horizontal (0 o'clock) maybe its about 11.30 o'clock. At assembly time i set it correctly but when i tight the heatblock against the nozzle it rotate a bit. Does your design have some clearance or i do need to dissamble extruder body and proper rotate the v6 assembly?

Also can a grill/protector be added to the fan?

Re: Does someone want to know how fast they can print/extrude? look here

Not much tolerancing you will need to rotate the assembled hot-end assembly by rotating the heatsink in the extruder body. Yes a grill/protector can be added and I should probably do so as the top part is on the verge of needing supports to print and that would solve that issue. I'll add it to the production design as it will have minimal impact on air flow.

As far as development speed goes is one to two hours per design change and five hours to print. Then a further two to three hours to test. So all in all each iteration takes nine to ten hours so it is two iterations a day as I only spend three hours daily actually working on it and the rest is printer time while I am working or sleeping.

Regards,

Martin

Martin Wolfe

Re: Does someone want to know how fast they can print/extrude? look here

Ah nice! Please post results. I'm very curious about this.

[...] Meanwhile, curiosity got the better of me, and I ordered the so-called 400mm/sec PLA whose link I posted above, despite my general denouncement of PLA. Well, if anything can print that fast, I'd like to see it first hand!

Will do. For some reason they shipped it from London, not their New York store, so unfortunately I won't be receiving it until the later half of next week. 🙄

Re: Does someone want to know how fast they can print/extrude? look here

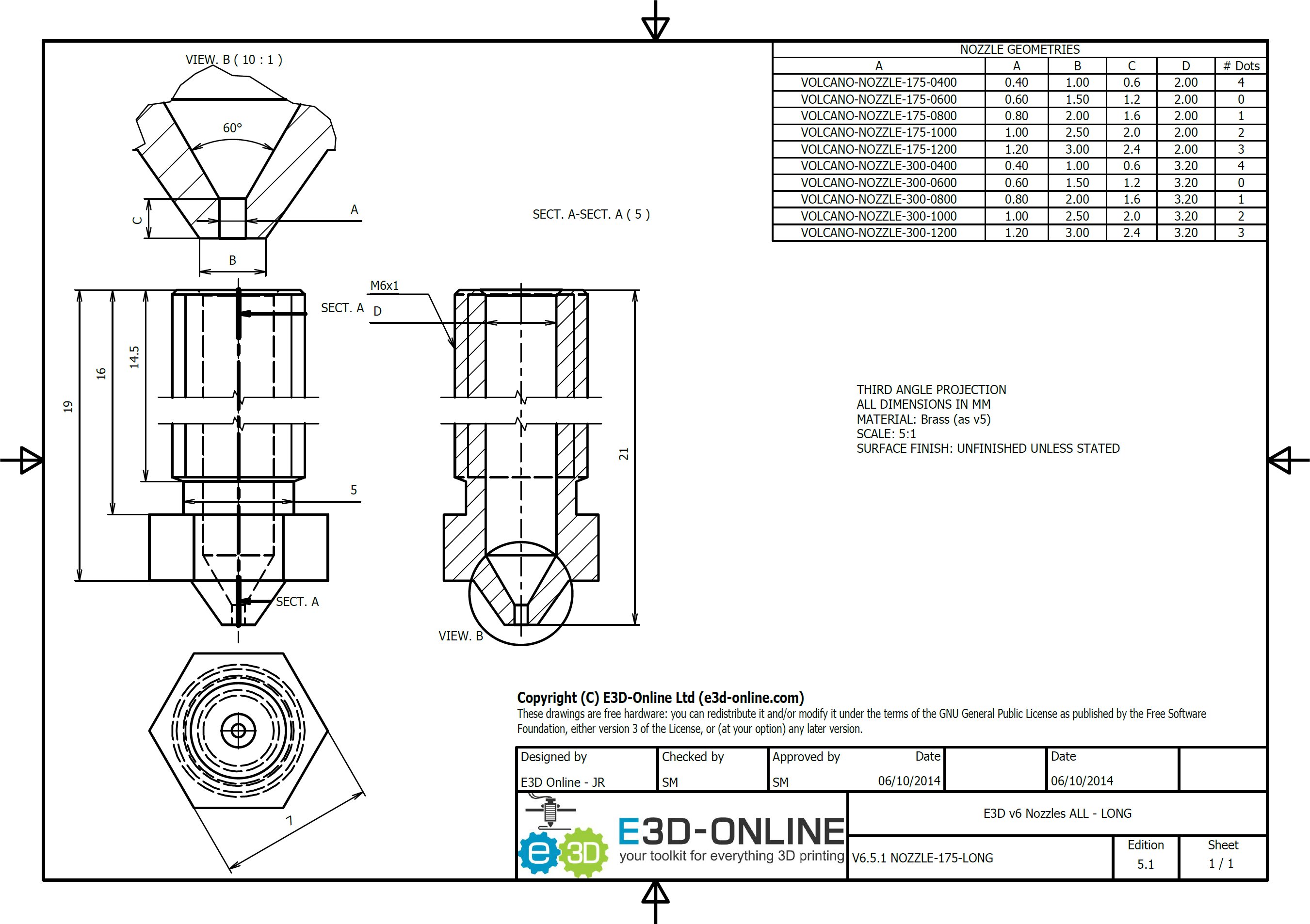

Martin, about your drawing https://shop.prusa3d.com/forum/hardware-firmware-and-software-help-f64/does-someone-want-to-know-how-fast-they-can-print--t19284-s170.html#p96688 where do you find nozzle dimentions? Do you have from 0.6mm and 0.8mm nozzle? I wan't to know max line width from that nozzles

Re: Does someone want to know how fast they can print/extrude? look here

I found the dimensions on the E3D website

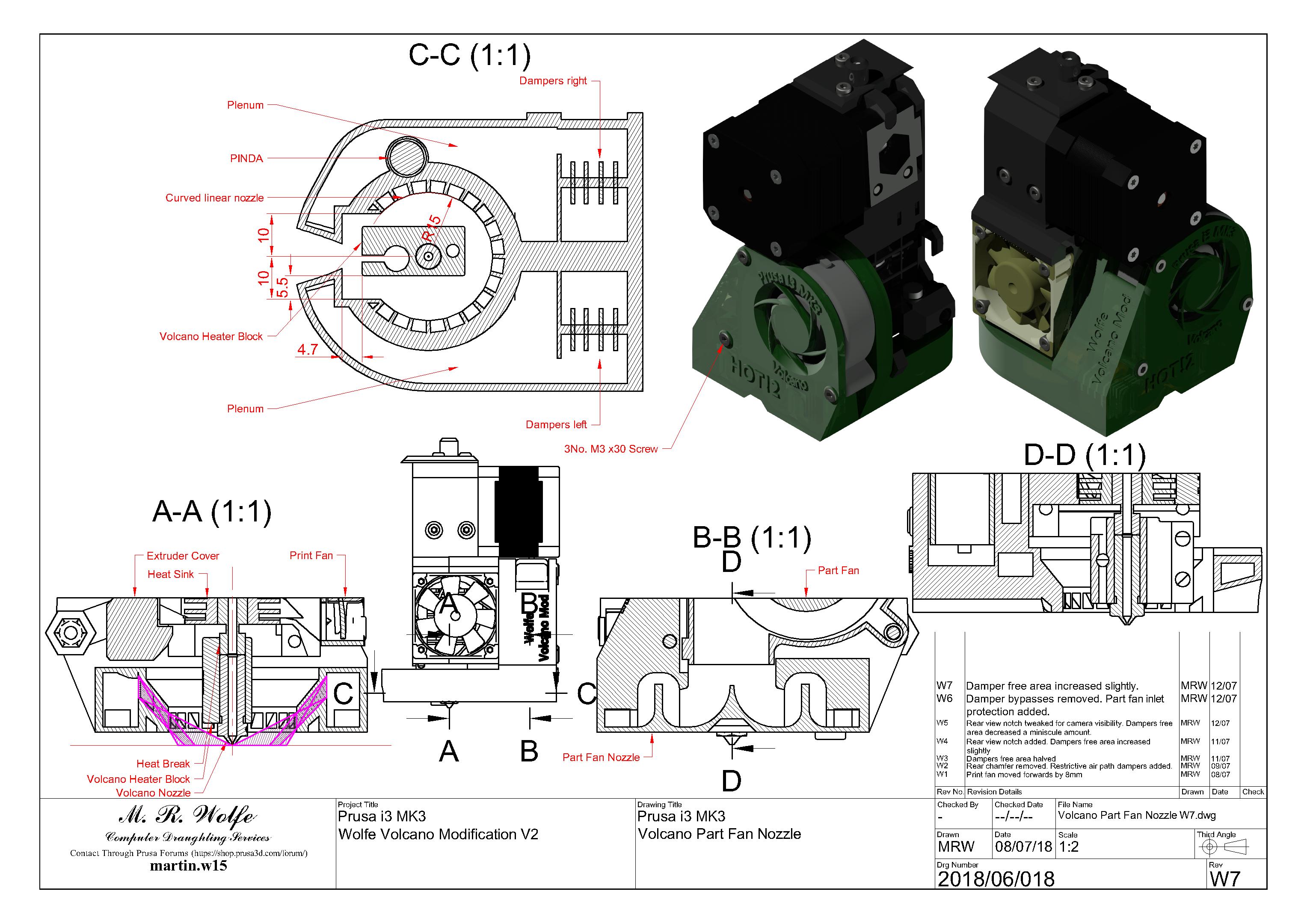

Now with regards to my W5 iteration the test Benchy came very close but still slightly over cooled.

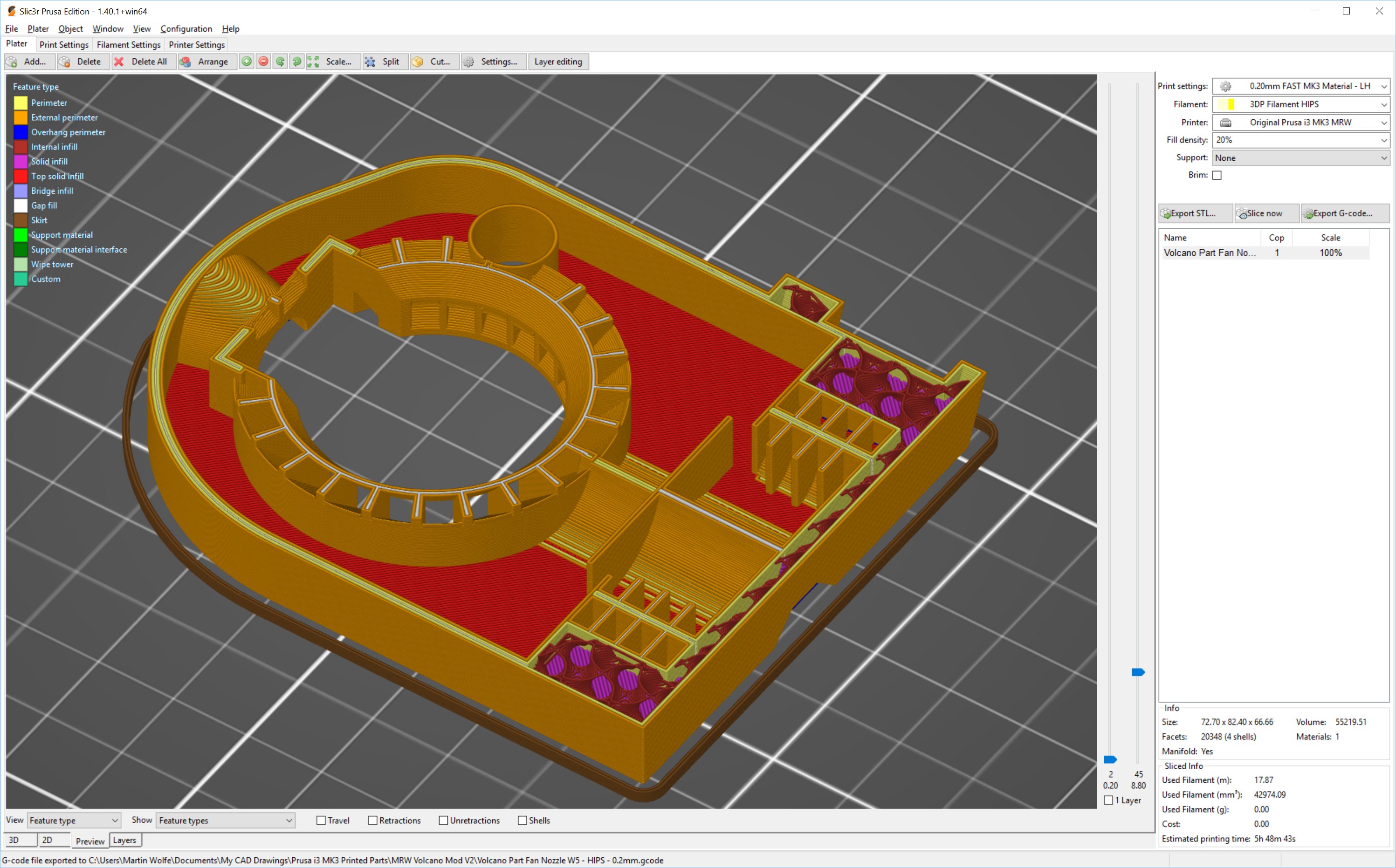

I have the W6 iteration printing at the moment. it has around 30min left to go. It has partially failed around the print fan inlet grill/protection but will be usable for testing purposes. If it passes tests it will have to be printed with supports to the build plate.

Regards,

Martin

Martin Wolfe

Re: Does someone want to know how fast they can print/extrude? look here

Nice thank you. Giving B we can say the max line width for 0.4mm nozzle is 1mm and for 0.6mm nozzle is 1.5mm? And maybe subtract 0.2mm to be safe?

About the shroud, you design looks like have lot of ducts and cover the nozzle at every angle, maybe we have to ajust the slic3r because software is defined for stock shroud. But your design much better than the stock 😎

Re: Does someone want to know how fast they can print/extrude? look here

About the shroud, you design looks like have lot of ducts and cover the nozzle at every angle, maybe we have to ajust the slic3r because software is defined for stock shroud. But your design much better than the stock 😎

Well, presumably you'd have to adjust the fan speed, yes, but nothing else, right?

On the other hand, the greater efficiency should open up new options as far as printing fast goes.

Re: Does someone want to know how fast they can print/extrude? look here

I've been noticing that my calibrated extrusion multiplier seems to vary depending on the print speed. Anyone else notice this? I'm not sure if this has led to any failures or not on the speed tests, which seem to assume a single extrusion multiplier.

Re: Does someone want to know how fast they can print/extrude? look here

I would say 0.3mm but 0.2mm should be OK.

Well the W6had a mixture off under and over cooling as well as a slight failure in it's own print. I get the feeling that the speed regulation on the fan is not very good as I saw the fan speed varying between 1560 and 1660 RPM when I had the fan speed manually set to 255 on the LCD panel. With a constant air load on the fan and a constant voltage from the Einsy board I do not expect the fan speed to vary by the reported 8%. Makes it very hard to dial in.

The only change I have made between W6 and W7 is to increase the free area of the dampers. I get the feeling that any tweaks after this will be very slight and need to be done in Slic3r. I was hoping to get it just right so no changes in settings were necessary.

Regards,

Martin

Martin Wolfe