Crashes, Layer Gaps, Stringing and Irregularity

Hi, I am troubleshooting my MK3S printer and don't know what to do next. My printer was originally an MK3 and I upgraded it to an MK3S. After the upgrade, I did a fair amount of printing and didn't have any trouble whatsoever. Recently, I've been printing the face shield headbands and have been having a ton of trouble getting clean prints. I've done a lot of research and already did quite a bit of troubleshooting, just looking for help with the next steps.

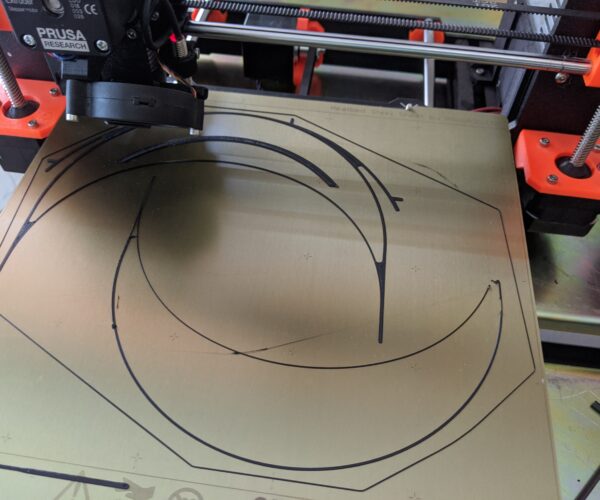

The symptom presents as irregularity in some layers and artifacts where the filament has "squeezed out" in the middle of the print, at random. The artifacts are usually easy to break away from the part but I've also noticed that some layers are not consistent throughout the part. In my troubleshooting today, I also observed some gaps in the outer shells of the first layer. Overall, it seems the printer is not extruding consistently and that's causing the issue however I also watched the printer go through several "crashes" mid print yesterday. No actual collisions, just the printer stopping in the middle of a layer as if it detected a crash and then restarting that layer where it stopped. The failure status showed the majority of these on the Y-axis. I researched that quite a bit and many people are reporting false crash detections, which led me to disable crash detection.

Things I've done so far:

- Printer self test, passed 100%

- Checked axes for smoothness and tightness, no notchy or difficult movement noted on any axes, no contact between parts

- X and Y belt status numbers within reason (270-280), though I read that these can be a poor indicator of belt tension

- Extruder alignment check and tension check

- Cold pull cleaning of nozzle using PLA, no significant chunks of material noted

- Z axis calibration

- First layer calibration

I'm currently running Overture PETG and using Prusa Slicer Generic PETG presets with some changes to shell quantity and infill. The thing that's getting me is that I'm running a second MK3S right next to the trouble printer, same settings, firmware, gcode and filament, and it's running perfectly all day long.

Thanks in advance for any help!

RE: Crashes, Layer Gaps, Stringing and Irregularity

Check the tension on the springs of the extruder, more pressure ?

Print hotter.

Give more info, temperature3, photo's.

RE: Crashes, Layer Gaps, Stringing and Irregularity

Can you post a pic (drag it into the edit area) showing the extrusion issue?

What firmware are you running? I recall that there some issues with false crash detection in earlier firmware releases. 3.8 has a bug that can cause problems with the filament sensor. You can try disabling the filament sensor as a quick test.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Crashes, Layer Gaps, Stringing and Irregularity

Thanks for the replies. Changing temps would seem odd to me since I have a second printer running an identical setup and everything is running fine. Also, these settings have worked well for me with this filament for some time now. This seems to have slowly progressed into an issue and I'm assuming its something mechanical at this point. Just trying to change one thing at a time. Do you think I've ruled out everything mechanical?

Firmware is 3.8.1-2869. Temps are 230 extruder / 85 bed on the first layer and 240 extruder / 90 bed on remaining layers. My filament sensor already appears to be disabled.