Crash Detected

My Y-axis seems to be acting up on me. not only can it not calibrate but it also doesn't move as freely as the others when I'm pushing it with my hand. When the printer does its pre-print calibration, the bed and frame will collide before it stops and moves onto the next axis. My printer is due for a firmware update, would that help it?

RE: Crash Detected

My Y-axis seems to be acting up on me. not only can it not calibrate but it also doesn't move as freely as the others when I'm pushing it with my hand. When the printer does its pre-print calibration, the bed and frame will collide before it stops and moves onto the next axis. My printer is due for a firmware update, would that help it?

If bed and frame collide, there is a mechanical fault. A firmware update will not help.

Check the assembly again and do not forget to lubricate the axles. The U-bolts on the Y-axis should also not be too tight, otherwise the linear bearings will jam.

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.

RE: Crash Detected

Very common build issue is users over tighten the U-bolts that retain the Y bearings. These bolts need to be snug, not tight. Just snug enough the bearings don't rattle. If you do tightened them, the U-bolts crush the bearing case and the rollers inside will seize.

RE: Crash Detected

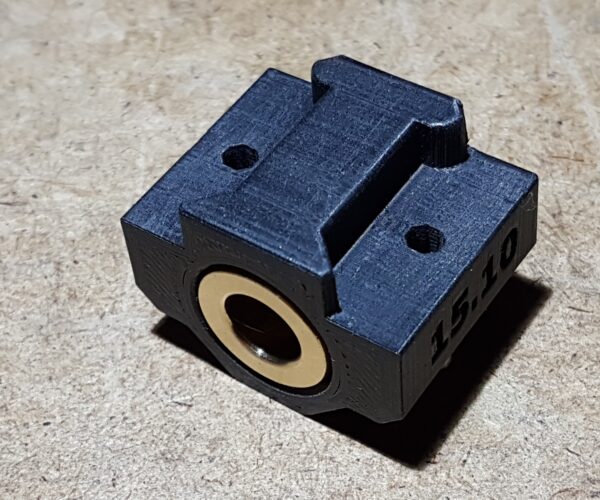

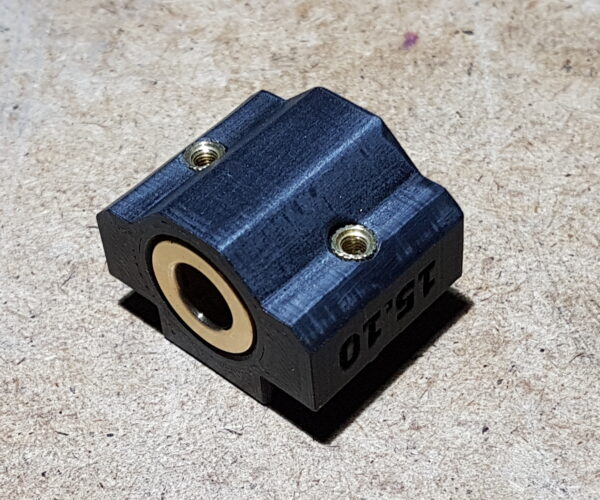

I didn't like that on the Prusa printer, so I designed and manufactured special housings (1 floating bearing / 2 fixed bearings):

(Installed on both MK3 and Mini)

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.

RE: Crash Detected

@karl-herbert

How did you deal with the clearance issues those carriers cause? Oh, wait, those are smaller diameter bearings, not LM8's.

Out of curiosity, did you look up the life of the smaller bearings? I tried to outsmart Prusa and installed smaller diameter Misumi 6 row bearings, they wore out in less than a year. A bit better than the Prusa bearings, but not as long as normal Misumi LM8's. Then I looked at bearing life and found the smaller diameter models have a much smaller load capacity and life expectancy.

ps: very nice design for carriers. I like them.

RE: Crash Detected

@tim-m30

I used brass slide bearings here. These have the dimensions od15xid8xle24mm, so the same dimensions as the LMU8 bearings. The holes in the case were made slightly larger and the brass bearings were glued with heat-resistant silicone. The bearings have lubrication grooves and are filled with grease. They run much smoother than the linear bearings and have not shown any wear so far. Later I will probably change to sintered bearings. Smooth running, maintenance-free and durable.

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.