Re: Constant clogs preventing printer operation

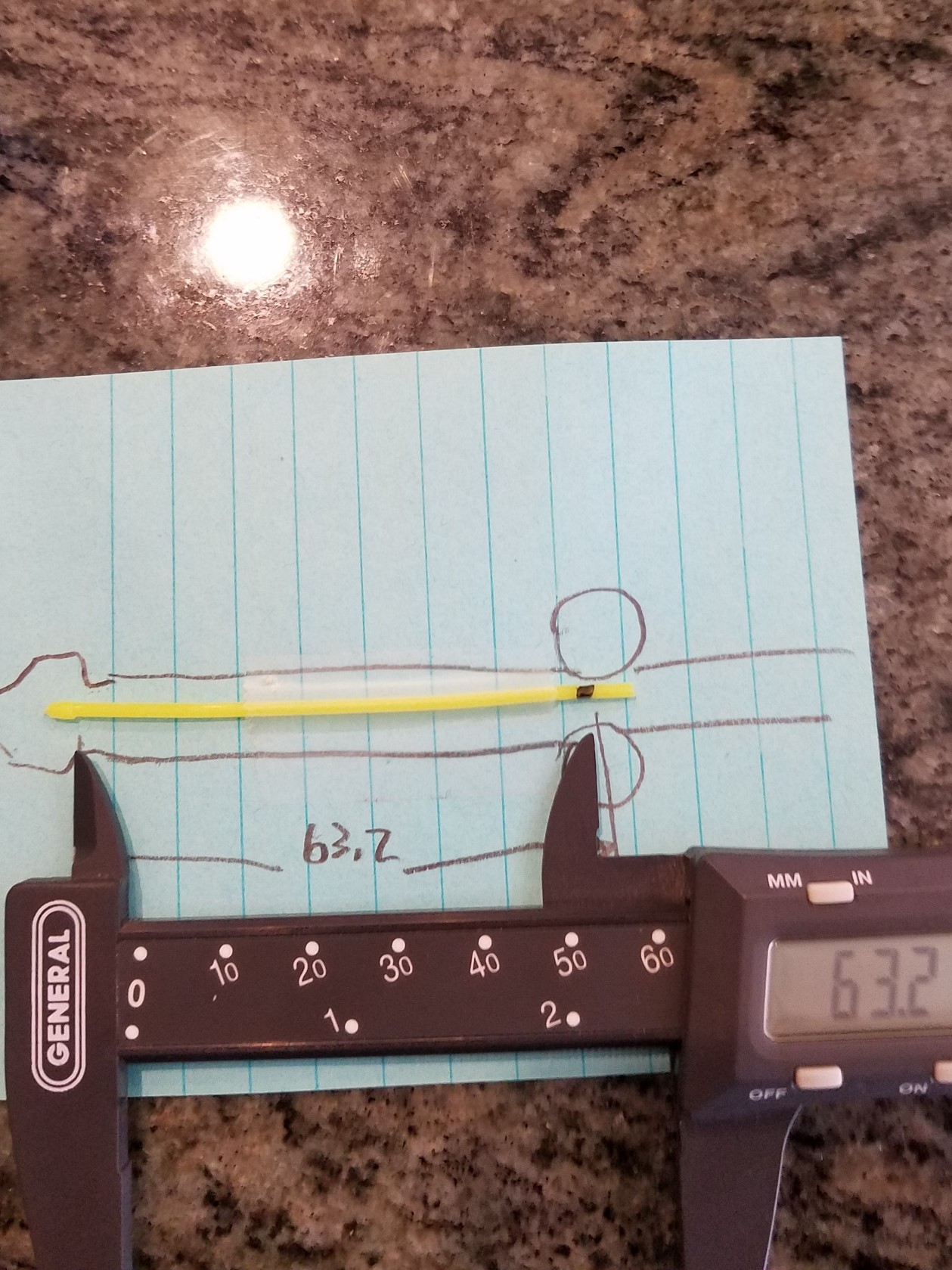

Hope this image may be helpful in your discussions. That's the measure of my Extruder (version 3).

Andre's problem seems to lie just in the end of the cylindrical heat sink.

yes, that's a really good image and lines up pretty accurately with with my measurements and "guesstimates" on where the clog was lining up.

Re: Constant clogs preventing printer operation

I think that some clog problems occur when the Teflon tube is not properly mounted.

There must be no gap in the teflon tube, and it must be firmly pressed against the bottom of the hotend.

The black locking ring must be pulled upwards when pushing down the teflon tube.

Then there will be no hole-space where the filament can be squeezed out and form a clog.

Bear MK3 with Bondtech extruder

Re: Constant clogs preventing printer operation

I think that some clog problems occur when the Teflon tube is not properly mounted.

There must be no gap in the teflon tube, and it must be firmly pressed against the bottom of the hotend.

The black locking ring must be pulled upwards when pushing down the teflon tube.

Then there will be no hole-space where the filament can be squeezed out and form a clog.

This is actually what I initially thought was the problem and have replaced my PTFE tube 4-5 times trying to fix it. I even designed and printed a little lock (shaped kind of like a "C") to force the black lock ring to stay up because I was concerned it was getting pushed down while I was putting the heat sink assembly into the extruder housing. I've also beveled the PTFE tube as recommended (using https://www.thingiverse.com/thing:2908391 ) and pushed the PTFE in with as much force as I can without bending it (sometimes it has bent and I've had to pull it out and restart with fresh tube). Do you know where the measurement between the top of the heat sink and end of a properly seated PTFE tube is? If so I'll measure it next time I have to tear down the extruder assembly.

Based on my measurements between the ground down portion of my filament (marked with black magic marker for visibility) and the clog:

the clog is occuring at ~63mm below the CL of the drive gear which places it below the bottom of the PTFE when I hold the filament scrap next to the extruder assembly or measure with a ruler or compare against the extruder assermbly cut away picture someone posed earllier in this thread.

If you have any suggestions to ensure proper seating of the PTFE tube or confirm that it's been seated correctly though outside of what I've tried already I'd gratefully give them a shot.

Re: Constant clogs preventing printer operation

If you have the hot end apart again, try finger tightening the heatbreak into the heatsink, then back it out 1-2 threads. Insert the PFTE tube fully and lock it. Then fully tighten the heatbreak.

It's possible that you have a bent or defective heatbreak. Have you considered replacing it with the Micro Swiss part? It's $16 on Amazon ( https://amzn.to/2M02lqI ) and better for most purposes than the more expensive E3D titanium heatbreak.

Re: Constant clogs preventing printer operation

If you have the hot end apart again, try finger tightening the heatbreak into the heatsink, then back it out 1-2 threads. Insert the PFTE tube fully and lock it. Then fully tighten the heatbreak.

It's possible that you have a bent or defective heatbreak. Have you considered replacing it with the Micro Swiss part? It's $16 on Amazon ( https://amzn.to/2M02lqI ) and better for most purposes than the more expensive E3D titanium heatbreak.

Last I had the extruder apart to do the R3 upgrade (~2 weeks ago) I removed the heatbreak and applied thermal compound. At the time it didn't appear damaged or bent so if there is something wrong it's inside where I can't see. However the amazon page for that heatbreak you are suggesting makes it sound like a good replacement and I'm certainly willing to try it for $16 bucks so I have one on the way.

Next time I break it down (maybe when I install that part) I'll see if I can try your method of tightening for sure.

Re: Constant clogs preventing printer operation

According to my drawings based on custom measurements and detailed drawings available on the internet, it should be 16.5 mm from the top of the heat sink (aluminium part) to the top of the teflon tube.

Looking at the bontech wheels, you only see about 0.3 mm of the Teflon tube (extruder R3).

Bear MK3 with Bondtech extruder

Re: Constant clogs preventing printer operation

According to my drawings based on custom measurements and detailed drawings available on the internet, it should be 16.5 mm from the top of the heat sink (aluminium part) to the top of the teflon tube.

Looking at the bontech wheels, you only see about 0.3 mm of the Teflon tube (extruder R3).

Ok, when I install the microswiss heatbreak in about a week I will verify 16.5mm for sure (before and after the heatbreak install).

I can also try to gauge the amount of PTFE peaking out into the gear chamber, that'll be tough to measure accurately. but I can visually verify that it's at most in the 1mm range at least.

Thanks much for the info!

Re: Constant clogs preventing printer operation

Here is an updated drawing where I have corrected the dimensions.

I did not manage to edit my last post so I removed that image and attached a new update here.

The new dimensions are taken from E3D-ONLINE's drawings, Extruder V6-175.

Bear MK3 with Bondtech extruder

Re: Constant clogs preventing printer operation

Here is an updated drawing where I have corrected the dimensions.

I did not manage to edit my last post so I removed that image and attached a new update here.

The new dimensions are taken from E3D-ONLINE's drawings, Extruder V6-175.

Ok, 16.7mm from top of heat sink to top of 50mm PTFE for a properly seated PTFE. I will check that on my next tear down.

Thank you sir!

Re: Constant clogs preventing printer operation

Just in case someone with my issues read though this thread I wanted to update with my final (Fingers crossed) fixes. In a fit of poor experimental procedure (and extruder tear down exhaustion) I installed both the R3X + 40mm Noctura Fan ( https://www.thingiverse.com/thing:3072016 ) and the Microswiss heat break ( https://www.amazon.com/gp/product/B06WGRJK1B/ref=oh_aui_detailpage_o00_s00?ie=UTF8&psc=1 ) at the same time.

After initially cranking up my print temperatures a month or two ago (which seemed to make the frequency go down a little but hard to tell) and then finally installing these two together 2 weeks ago I haven't had any more clogging issues so far. I did have a string of failures immediately prior to commencing the last two changes so there was a marked change before and after the installs.

I did not try any of the PTFE tightening methods suggested above (I forgot in the confusion of the tear down) and just crammed it in as hard as I could like normal.