Check axis length error after belt and stepper motor upgrade on MK3s

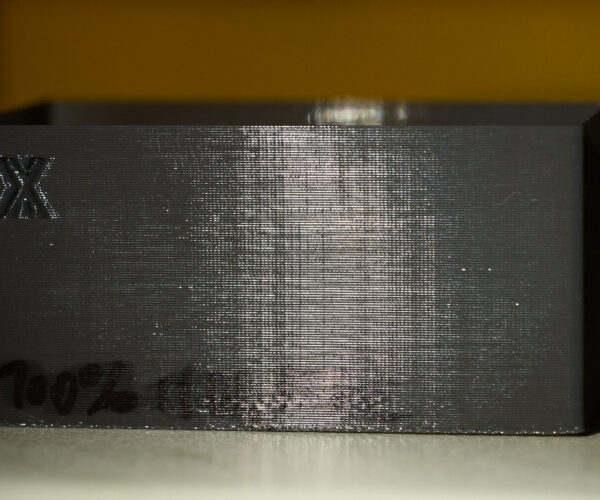

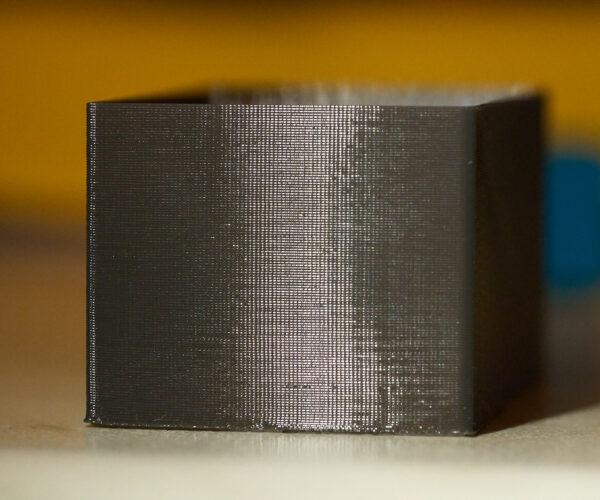

After successful MK3s printer assembly and 100+ hours of happy printing i make decision upgrade stock LDO motors and belts to eliminate VFA. Before upgrade my belt tension values in "Support" menu were 273 and 278 for X and Y respectively.

I replaced stock LDO motors with Moons MS17HD2P4100 (1.8 degree, 1A, 3.9Ohm). Stock belts were replaced by GATES-LL-2GT. Stock smooth idlers were replaced by geared idlers with 20 tooth. X axis was completely replaced by Bear version.

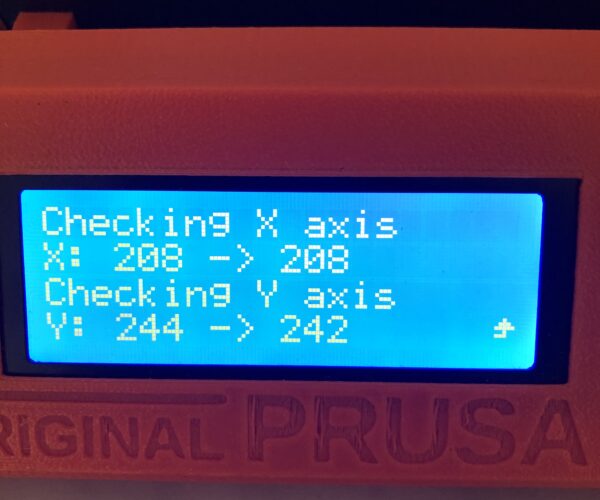

After upgrade printer can't successful complete belt tension test. Test yields error "Check axis length - X". Belt tension values in Support menu now are 190 and 230 for X and Y respectively. Despite this, printer works just fine, all motors are quite cold. Print quality is now little better. Motors sounds more quieter.

RE: Check axis length error after belt and stepper motor upgrade on MK3s

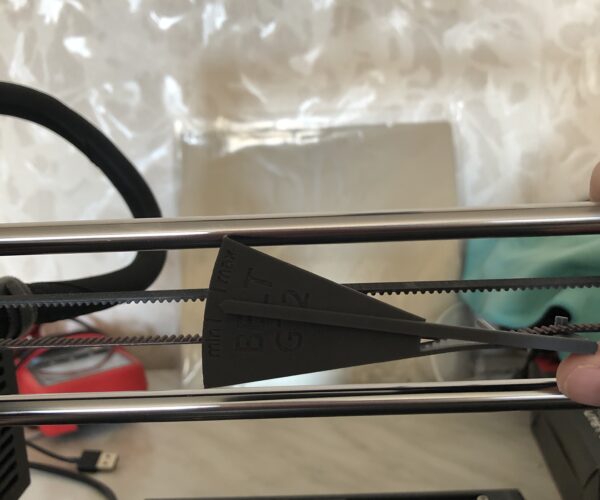

The tension and the travel length are two different things. I have no idea how you would come up with new range for your replacement belt - so I'd assume it would need to be close to what the old one was and guess from there - for tension my preference is to download the PETG gcode from Prusa for the belt tension meter.

For axis length error, I'd guess that the travel pressure on the X axis is tripping up the end stop detection logic. If the axis binds anywhere along a motorized axis traversal, the software declares it the new zero, or the new end stop distance. If the two values are not the correct length for the firmware's expectation for the Mk3s (bed width, bed x zero) then you get that error.

Check your print head back-plate tension - if it is squeezing the bearings even a little, it'll generate false end stop detection.

I'm disappointed you only got a little improvement. I have the moon motors and the new gears, but not the new belt - hadn't read that would be required. I was waiting to find someone who was in front of me (you) ...

RE: Check axis length error after belt and stepper motor upgrade on MK3s

Yes, improvement was noticeable, but not huge (in terms of VFA) :(.

During belt tension test extruder head goes exactly to the end and back to zero and after that yields x-axis length error. Strange thing.

RE: Check axis length error after belt and stepper motor upgrade on MK3s

I tried to loosen x-belt tension. Now it feels very weak but passes the test with the value equal to 221. (in comparison, old value 273 before upgrade with stock belt and motor felt very tight)

RE: Check axis length error after belt and stepper motor upgrade on MK3s

@enver

Do recommend downloading the PETG pattern for Prusa & co belt tension device. Is right up there with the greaser. The sensor derived tensions are better than nothing and do inform on the perceived tightness for the sensorless endstop detection.