Changing Print speed via LCD display (>>%) how can I do it in slic3rPE?

I have an i3 MK3 I purchased in 2018 I'm still running the original firmware (V 3.3.1-845) on, and I'm still using (Slic3r PE V1.41.0+win64). I have thousands of hours of print time and hundreds of thousands of meters of filament have been fed through it. In all this time I haven't had to mess with to many settings in Slic3r PE beyond some minor adjustments to the default profiles. I've printed with many different brands of PLA, PETG, and ABS, pretty much flawlessly with little fuss and achieved great results.

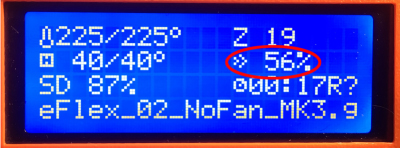

Now, the project I'm printing requires TPE/TPU , and perhaps somewhat surprisingly, I'm getting great results, even on the lower end of the FDM printable durometer scale, Ninjaflex at 85A for example. That said Ive been getting these results by changing the print speed on the LCD screen, not by understanding and using the settings in Slic3r PE as they pertain to TPE/TPU's.

This is less then Ideal, I've been looking for information on what this setting is changing, so I could correlate it with the settings in Slic3r PE, but the best I can come up with is that it's somehow firmware related, and I have not found any 1 or 2 settings in Slic3r PE that will achieve the same result as the adjustment on the LCD does.

I guess I'm looking for some sort of guide or guidance that will help me understand what needs to be changed, and how these changes might affect different prints using the same material. ( I have read the manuals )

Any help is appreciated

Best Answer by bobstro:

There are multiple aspects to your question, so let me work through them.

- When you rotate the front knob, you are setting the feed percentage directly in Marlin on the printer. If you issue an M220 Sxx gcode command directly to the printer using a terminal program, you'll see the front indicator change accordingly. This affects the rate of filament feed for all printer moves with extrusion. It has the effect of slowing everything down. You could insert M220 Sxx commands into your startup gcode, but there are better strategies (see below).

- If you change your slicer speed settings, you can slow the speed used for printing specific features (e.g. infill, perimeter walls). This gives you finer control, and the speeds are reflected in the gcode, so you don't need to worry about a manual setting on the printer before reprinting the file. It's been a while since I used an older version of Slic3r, but I believe speeds are still under Print Settings->Speed. This will give you repeatability, which is what you're after.

- If you're overall happy with your print settings and just want to print tricky filaments (flex, carbon fibre-filled), the most elegant solution is to change the maximum volumetric rate used by the slicer to limit speeds. This is one feature unique to Slic3r/PrusaSlicer among the mainstream slicer. If you change Filament Settings->Advanced->Print speed override->Max volumetric speed (MVS), you are setting an upper limit for the amount of filament that can be pushed through the hotend in a given time. This is the ideal place to put a limit on prints made with one specific filament with unique requirements, and I use it often. The effect is that the slicer will use speeds up to those you specify normally (under Print Settings->Speed), but will limit speeds if the volumetric rate (i.e. Layer Height X Extrusion Width X Speed) would exceed the specified rate as measured in mm^/s.

In your case, it sounds like you're very much in a "if it ain't broke, don't fix it" mode, so I'd try adjusting MVS for a filament profile for your TPE/TPU prints. Start low (e.g. MVS = 1 or 2) with some small test prints and verify it works properly at low speeds, then you can try adjusting MVS upwards.

In summary:

- M220 Sxx gcode commands limit the feed rate (speed) for all printer moves, independent of gcode.

- Setting individual speeds under Print Settings->Speed lets you tune individual print feature speeds.

- Setting a maximum throughput rate under Filament Settings->Advanced lets you set an upper limit on speeds (flow rate) for a specific filament.

I'm also using a 2018 Mk3 hardware configuration, although I've updated to newer firmware and slicer versions. The original Mk3 configuration prints very well, IME.

The Filament Whisperer

RE: Changing Print speed via LCD display (>>%) how can I do it in slic3rPE?

There are multiple aspects to your question, so let me work through them.

- When you rotate the front knob, you are setting the feed percentage directly in Marlin on the printer. If you issue an M220 Sxx gcode command directly to the printer using a terminal program, you'll see the front indicator change accordingly. This affects the rate of filament feed for all printer moves with extrusion. It has the effect of slowing everything down. You could insert M220 Sxx commands into your startup gcode, but there are better strategies (see below).

- If you change your slicer speed settings, you can slow the speed used for printing specific features (e.g. infill, perimeter walls). This gives you finer control, and the speeds are reflected in the gcode, so you don't need to worry about a manual setting on the printer before reprinting the file. It's been a while since I used an older version of Slic3r, but I believe speeds are still under Print Settings->Speed. This will give you repeatability, which is what you're after.

- If you're overall happy with your print settings and just want to print tricky filaments (flex, carbon fibre-filled), the most elegant solution is to change the maximum volumetric rate used by the slicer to limit speeds. This is one feature unique to Slic3r/PrusaSlicer among the mainstream slicer. If you change Filament Settings->Advanced->Print speed override->Max volumetric speed (MVS), you are setting an upper limit for the amount of filament that can be pushed through the hotend in a given time. This is the ideal place to put a limit on prints made with one specific filament with unique requirements, and I use it often. The effect is that the slicer will use speeds up to those you specify normally (under Print Settings->Speed), but will limit speeds if the volumetric rate (i.e. Layer Height X Extrusion Width X Speed) would exceed the specified rate as measured in mm^/s.

In your case, it sounds like you're very much in a "if it ain't broke, don't fix it" mode, so I'd try adjusting MVS for a filament profile for your TPE/TPU prints. Start low (e.g. MVS = 1 or 2) with some small test prints and verify it works properly at low speeds, then you can try adjusting MVS upwards.

In summary:

- M220 Sxx gcode commands limit the feed rate (speed) for all printer moves, independent of gcode.

- Setting individual speeds under Print Settings->Speed lets you tune individual print feature speeds.

- Setting a maximum throughput rate under Filament Settings->Advanced lets you set an upper limit on speeds (flow rate) for a specific filament.

I'm also using a 2018 Mk3 hardware configuration, although I've updated to newer firmware and slicer versions. The original Mk3 configuration prints very well, IME.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Changing Print speed via LCD display (>>%) how can I do it in slic3rPE?

First, Bob I want to thank you very much for taking the time to spell this out as you have.

everything you've suggested makes sense to me, it made me feel comfortable that I had a good understanding of what needed to be changed.

I started with your suggestion of changing the Max volumetric speed, it was (1.5), changed it to (.75) this did increase the print time by almost double (as I hoped it would) I'm currently 46% along (at the time of writing) with the first test print and its printing exactly as I hoped.

I'm going to play a bit more with retraction and travel speeds now and see if they react accordingly, when changing the Max volumetric speed, I suspect they will.

Second, LOL @ "In your case, it sounds like you're very much in a "if it ain't broke, don't fix it" mode".

I was sure I was going to have to explain that to whom ever offered help on this topic, you nailed it.

There's a story behind it, that I'd love to tell, but for now suffice to say it's important that I continue to get consistent results, this is not a hobby for me.

By the way, I just bought an MK3s 2 days ago, so I can play with it, and not have to worry about potential bad firmware updates or changed filament profiles, and I'll be able to try out the newer software updates. I've been following them and I'm excited to try them.

Thanks again for your help,

Dan

The Filament Whisperer

RE: Changing Print speed via LCD display (>>%) how can I do it in slic3rPE?

Glad the info is helpful. Makes sense to leave a working production unit the heck alone! Have fun with the 2nd one.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…