Changed nozzle now every print fails!

I have had my MK3S since early this year. It has always worked great and I never had any issues with it. A couple weeks ago I replaced the stock nozzle with a new hardened steel nozzle. After putting it on there was major adhesion issues. I calibrated the z axis and ran the first layer calibration and got it to run through it like normal and the nozzle height and everything seemed fine.

I began to try printing a model and it would print the raft just fine but the model itself would curl up really bad on the outer edges. It eventually begins to collide with the print, stops, and tries to restart. It does this a couple times and then eventually stops.

The video below shows the adhesion issues I am still having with some of the prints I try. I need to re-do the videos of the model curling so I can get them under the upload size limit, but I wanted to see if anyone might have any advice before I start to take the printer apart and try to see what's wrong.

Any advice would be a big help!

RE: Changed nozzle now every print fails!

Looks like you're having adhesion issues. This makes sense if you've been working on the printer. It's usually a combination of Live-Z calibration and proper bed cleaning. I'm going to give you a big info dump here that summarizes everything on the topic...

-

A dirty PEI print surface. Even if you don't think this is the cause, it's always a good idea to make sure your PEI surface is clean before trying any other fixes. If it's a smooth PEI sheet, take it to the kitchen sink and give it a good dunk with Dawn (original formula, no vinegar or hand softener variants) dishwashing soap or your local equivalent (e.g. Fairy in UK). Use a clean paper towel to clean it off, and another to dry it. Avoid using any sponge or cloth that has been in contact with grease. Above all else, avoid touching the PEI print surface. Once it's good and clean, you should be able to use 91%+ isopropyl alcohol between prints, 100% acetone when that fails , and another dunk when acetone fails. Worst-case, use a 3M 7445 ScotchBrite pad or equivalent on smooth PEI to give it a very light buff, but only infrequently. If you've got a textured powder-coated PEI print surface, the official instructions are to use 91%+ isopropyl alcohol on it only. Rumors persist that some tribes deep in the jungle have had good luck getting started with these sheets by giving them a wipe with 100% acetone and a dunk with Dawn. Either way, there's no real warranty on these sheets. YMMV.

-

If you have not already done so, try using Jeff Jordan's "Life Adjust" procedure for calibrating your Live-Z setting. It is much easier to use and understand than the on-board routine and much easier to make mid-print adjustments accurately with. In general, start high (less negative) and work lower (more negative) in large increments (e.g. 0.1mm) until the filament starts to stick on its own. When you've got your Live-Z setting adjusted properly, you should be able to gently rub the extruded lines on the PEI surface without dislodging them. Then start lowering (more negative) the level until there are no gaps between layers. You should not be able to peel the lines apart after printing, but the top should be regular.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Changed nozzle now every print fails!

I have had my MK3S since early this year. It has always worked great and I never had any issues with it. A couple weeks ago I replaced the stock nozzle with a new hardened steel nozzle.

Did you follow the E3D nozzle replacement and assembly guides? If that answer is no, then you are having problems because the hot end was not reassembled correctly. There are subtle but quite necessary steps in their instructions.

Second, the hardened steel nozzle requires a change to printer settings. Did you make these changes?

Third, it is unclear why plastic is not sticking to the print surface, but my initial guess is you are using PLA and a layer of oils has been spread over it. Using paper towels dampened with alcohol will not remove oils effectively. It takes a large quantity of alcohol to remove lots of fingerprints, especially if the user has eaten at a mid-eastern or Italian restaurant where dipping bread into oil is common. In this case, you also should understand the alcohol is quite effective at removing the oil from fingers and moving it to the print surface. Yes, I am exaggerating here, but this has happened to me.

Said another way - a good deep clean at a sink using dish detergent and hot water goes a long way to restoring printability.

RE: Changed nozzle now every print fails!

@tim-m30

Thanks for the reply! With this and the first response I got I guess I will start with scrubbing it down with some dish soap and see what happens. I am skeptical because i can get the raft for other prints to come out fine and then the actual model goes to hell. I will start with the deep clean though.

RE: Changed nozzle now every print fails!

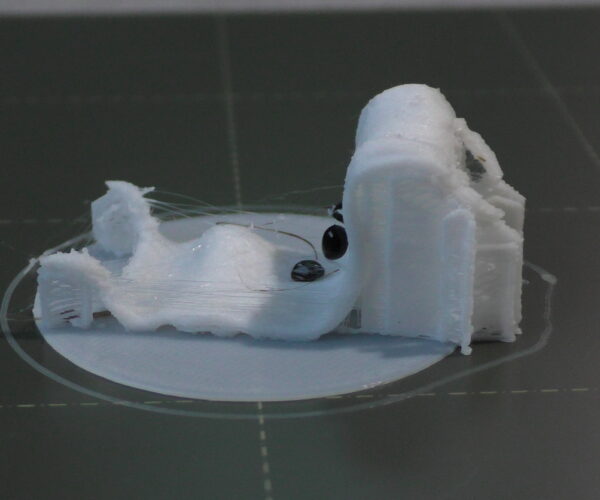

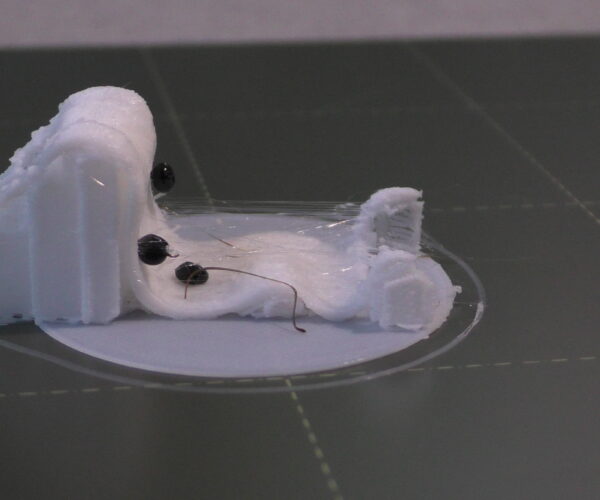

So I started with that advice and scrubbed down my buildplate with dish soap. I printed the same file in the video and the first print stuck and here is the result:

It definitely needs some tuning but from this it looks pretty good compared to the video I posted.

However as you can see from these photos it printed with these small black blobs stuck to the model. My guess is burnt filament? But I'm not sure? Anyone have an idea as to what that is and how to fix it?

RE: Changed nozzle now every print fails!

Yep burnt filament, thats almost 100% an indication that you didn't fit the nozzle correctly.

RE: Changed nozzle now every print fails!

@neophyl

The nozzle is threaded all the way in. There must be a gap inside somewhere? Any tips on fixing that could keep me from having to dismantle the hotend/extruder?