Can't load filament

Relatively new i3 MK3S owner here.

I've been printing with black PLA filament for a while, and want to switch to silver filament for a new piece.

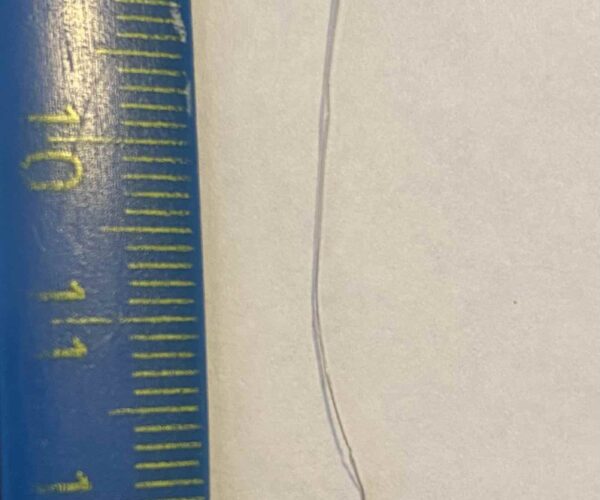

I used the LCD->Settings menu to unload the black filament. It heated up and then prompted me to pull filament out immediately. The filament didn't come out easily -- I used a fair but of force to extract it, and it snapped inside the extruder assembly. The end of the removed filament shows some signs of melting. It's 1.75mm in diameter, then narrows to a very thin thread that's about 1mm long.

I tried to load the silver filament, but it won't load. I can get it inserted into the feed hold, and the feeder pulls it in a little way, but then it stops and won't advance further. When I go through the load process, the LCD asks me whether it's extruding and the correct color. I say no, and it repeats its attempt to extrude filament, then displays the same question.

I followed the instructions to clear a clog here:

https://help.prusa3d.com/article/clogged-nozzle-hotend-mk3s-mk2-5s_2008

A tiny amount of black filament dripped out of the nozzle, but now that doesn't happen. I used the acupuncture needle as instructed. It comes out clean. My attempts to reload the silver filament fail repeatedly in the same way: I put it in the feed hole, it gets pulled a tiny bit in, then doesn't advance further and nothing is extruded.

Help?

RE: Can't load filament

Unfortunately you may have a clog of the type that can't be cleared without disassembly.

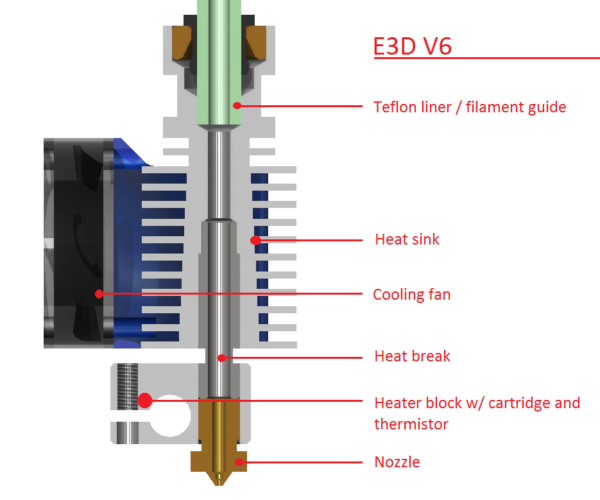

I've seen this a couple of times where the filament gets jammed in the area of the filament guide and heat sink.

A couple of times, I was able to release the tension on the extruder and use a dental explorer to carefully pry out the blocking piece of filament.

One thing you can try is to heat the hot end up to, say ABS/ASA temperature, let it sit for maybe 20 minutes or so, to let the heat rise, and again try to push filament through the system.

On my other printer (not Prusa) I had a case where needling came out clean but extrusion was weak. The culprit was remnants of scorched filament in the nozzle, which would break off and obstruct the flow. I had to disassemble it and clean out the top inside of the nozzle with a drill bit.

RE:

This probably isn't the usual clog at the nozzle, it reads like you pulled a blobbed end partway up the extruder and broke it off near the top.

You may be lucky and have issues higher than @jsw suggests so try this first.

Attempt to load - it will fail, now use a sharpie to mark the filament at the point it enters the extruder, and unload it.

Hold the marked point at the same level against the extruder and you will see how far down the blockage is.

Near the top? Open the extruder idler and look - sometimes the blocking scrap is visible and can be removed easily...

Your next step would be to heat to about 10 degrees over printing temperature and, with the idler open, push down a length of filament until it runs through the extruder carrying the blocking fragment with it. Once pushing through easily pull it out quickly and it should not reclog.

The cause:

This might be a one-off but IF this recurs you may have a damaged PTFE tube in the extruder or, more likely, the tube compression collet at the top has failed or was incorrectly fitted.

Cheerio,

RE: Can't load filament

Thanks, guys.

I tried @jsw's trick to try to melt the blockage out, but that didn't work. @Diem's trick for figuring out how deep the blockage was confirmed that it was right at the top of the hotend tube, just below the extruder-idler. I had to disassemble the printer to the point that I could get the hotend out of the frame. I picked this tiny little grain of busted filament out of the very top of the feed tube. Reversed my steps to reassemble, and it's working again! Have been through self-test, XYZ cal, first layer cal.

I had purchased the assembled version of the printer, so taking it apart was an adventure. I had no mental model for assembly. I worked through the E-axis chapter in the book, backwards, to the point that I could get at the hotend. Now I feel like a maker!