Can I use these lubricants of my MK2 or 3?

Hello,

I was researching for oil and grease to use on MK3 for the monthly maintenance. However, I did not get any clear answer to which produce to use. From what I gather is to use silicone base oil for the smooth rod and lithium base grease for the z screw lead and the bondtech gear. So my question is can I use this 3 in 1 for the smooth rod? Can I use this white lithium grease of the e-gear and z screw lead? If not, what are your recommend to be use?

thanks

iosman

RE: Can I use these lubricants of my MK2 or 3?

Don't let any form of lubrication touch the lead screws. It will damage the Delrin trapezoidal nuts.

My smooth rods are as dry as I can keep them. The bearings are packed with Superlube; they have grease seals to keep that grease in.

Bad things stick to greasy / oily rods - you don't want that to get sucked into the bearings.

RE: Can I use these lubricants of my MK2 or 3?

Lithium #2 grease for packing the bearings before assembly; Superlube #2 also works. Both available in tubes at any hardware store for about $5 US.

Oils work if you find a way to fill the bearings with oil during installation and then a way to keep the oil inside the bearings during operation. Oil also works if you assemble your printer then find out later you should have packed the bearing with grease because you are having friction problems that are destroying prints or causing crashes. Even then a tear down and packing the bearings is best for after the fact learning. 🙂

Seriously, lube the bearings with grease before you insert the rods... you'll not miss the entire "why is my printer crashing like this" ordeal you'll otherwise have in a month or two.

ps: As rmm said: do NOT grease the lead screws, the T-nuts are expensive.

RE: Can I use these lubricants of my MK2 or 3?

You are forcing me (I force easy) to put in a plug for a printable bearing greaser:

https://www.thingiverse.com/thing:1128781

There are a bunch of them - that is the one I use. Plus a cap to keep it clean.

RE: Can I use these lubricants of my MK2 or 3?

If you use a Lithium #2 grease, go for one with a low base oil viscosity. The Mogul LV 2 EP Prusa recommend has a base oil viscosity of 50, Superlube has a base oil viscosity of 65, but also contains PTFE which can build up, although I've yet to here anyone on these forums report bearing failures for this reason.

The #2 or EP2 is how thick the lithium soap carrier for the oil which is the lubricating part if the grease is, which determines how much it is going to stay where you want it to.

So a #00 or EP00 grease is semi liquid (Tomato ketchup) whereas a #2 or EP2 grease is thicker (Peanut butter), so do you want ketchup or peanut butter in your bearings? 😉

But in both cases, this has nothing to do with the actual lubrication, but rather the part that keeps the lubricating oil in it's place, and it's the oil that does the important work of lubricating the bearings.

So the next important part is the base oil viscosity, the higher the viscosity, the thicker the oil and the harder it will be for the bearings to move through it, but higher viscosities also keep the metal contact points separated better, too thick, you will definitely keep the bearing metal surfaces apart but you will move sluggishly and start to heat up the oil and the motor as it will require more current to move, thinner and you will be able to move a lot faster and easier and still keep the bearing contact points apart so preventing wear, too thin and you will not keep the metal contact points apart and get wear. Load will also affect this.

In this application we have small bearings lightly loaded moving at a fairly decent speed at times, but they are also re-circulating around the inside of the bearing, so need to be able to move quite quickly and freely, so the best grease would be quite thin with a low base oil viscosity.

EP2 or #2 will work as long as you don't pack the bearings fully (<30% MAX) and it also needs to have a low base oil viscosity, but you will need to re grease grease periodically, and in this application it's actually better to very lightly grease the rods rather than rely on this #2 grease to move about inside the bearing releasing oil to the bearing surface. It will initially, but once it is pushed out of the way, it requires heat to soften the grease so it flows into the voids where the bearings are moving and be able to release the oil again, hence why it is better to lightly grease the rods often.

A semi fluid grease EP00 or NGLi 00 would be better in this scenario as it naturally flows to fill the voids again, but getting one with a low viscosity base oil is very expensive and is normally used on aircraft (Rocol AEROSPEC 100).

To be honest there is not a lot of choice in these grades that is affordable and the best I can come up with is Penrite Semi Fluid and Steering Box Grease.

http://penriteclassicoils.co.uk/product/semi-fluid-and-steering-box-lube/

This has a grease thickness of NLGi 00 (Ketchup) and a base oil viscosity of 150, which will work, but maybe could result in increased drag at high speeds, but again I've not heard of anyone have any issues whom is using grease of this grade, plus the printer is not moving at full speed all the time anyway.

The other option is oil, but this means applying drops of oil onto the shafts regularly. This will result in the lowest friction and fastest possible movements, but the oil will require another drop every print and maybe more than one drop during an extra long print, also the excess that gets pushed to the ends of the rods will also need wiping off, but then again so will the grease.

Personally I oil using Singer sewing machine oil, but am considering changing to the Penrite NLGI 00 grease as I have too much ringing in my prints since the bearings have so little resistance to movement. A little damping would improve things which the grease would provide.

Normal people believe that if it is not broke, do not fix it. Engineers believe that if it is not broke, it does not have enough features yet.

RE: Can I use these lubricants of my MK2 or 3?

Chocki, how does your light oil stay on the top bearing circuit? Does it have some anti-gravity behavior?

As for fast, our printers are not fast in a bearing sense. They in no way come close to approaching the speed ratings for the LMU8's. Manufacturers discuss bearing speed in hundreds of thousands of millimeters per minute.

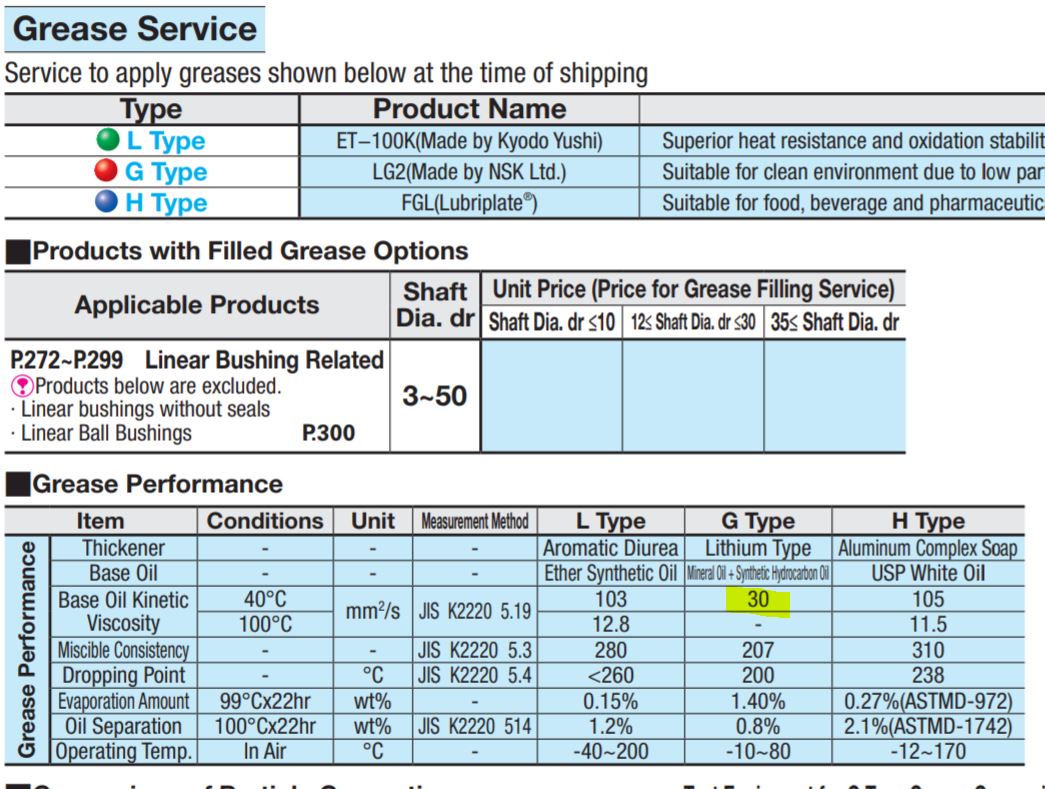

And Misumi's pointer on #2 lithium grease ...

RE: Can I use these lubricants of my MK2 or 3?

Like I said, a low viscosity base oil is required and recommended by Misumi, in this case a viscosity of 30 which is around the viscosity of sewing machine oils (Typically 28 to 32).

The oil does not stay in place, but remains on the surface leaving a wet film which also gets carried around the bearings, but migrates to the bottom / dries out with time, hence the need for repeat lubrication regularly, it does not run off like water off a freshly waxed car but remains held in place by capillary action and adhesion due to low surface tension of the oil. At microscopic levels the surface of the rods and bearings is far from smooth and this helps to hold the oil on the surface, but it will require replenishing.

Grease does this, since it is nothing more than a reservoir of oil, and applying drops manually also does this., But to release the oil, it has to come into contact with the grease, if the grease is thick, it will get pushed out of the way and remain pushed out of the way until softened by heat, or use a semi fluid grease, but even this will eventually need replacing as this too will eventually all run to the bottom of the bearing.

And stating use a #2 grease without any additional information is not ideal.

Three examples of #2 grease,

Mogul LV 2 EP base oil viscosity 65.

SKF General Purpose Industrial and Automotive Bearing Grease base oil viscosity 110

RENOLIT BLUE LX 2 base oil viscosity 158

So which one are you going to use?

And I never stated the oil somehow magically remains inside the bearing, else I would not need to apply drops where it is needed, on top of the bearing rod every print!.

Normal people believe that if it is not broke, do not fix it. Engineers believe that if it is not broke, it does not have enough features yet.

RE: Can I use these lubricants of my MK2 or 3?

If your going to say that the MISUMI engineer said to use an #2 grease, then he forgot to add, as long as it is NSK LG2 which has a base oil viscosity of 32!.

This is a low viscosity #2 grease unlike RENOLIT BLU LX2 which is a high viscosity #2 grease. They are both #2 greases but only one is ideally suitable for linear bearings.

As you can see, lubrication is not just a case of any old grease will do, even if some of it's specification is the same, in this case, the soap density. #2

Normal people believe that if it is not broke, do not fix it. Engineers believe that if it is not broke, it does not have enough features yet.

RE: Can I use these lubricants of my MK2 or 3?

If you read the fine print of Superlube, it as a base oil of 8 ...

As for oil on bearings, there is a reason bearings and oil are ALWAYS in a bath. It is to keep the bearings lubricated. If oil actually stay on the bearings, baths and pressure lubrication would not be needed. Oil wets a surface, sure, but oil is wiped off as the bearing rolls. And it doesn't take many rotations for a bearing to become effectively dry.

Misumi and others have linear bearings intended for oil lubrication: that have no seals and that have drip holes for oil to circulate. Oil is recommended for high speed applications (that 10,000 mm a second type of speed).

Sure, you can oil the bearings and try to work oil past the grease seals (it isn't easy) ... but why? Grease simply works as designed.

RE: Can I use these lubricants of my MK2 or 3?

Do keep in mind, Superlube is not a product. It is a family.

Amazon lists close to a dozen variations:

https://www.amazon.com/s?k=superlube&ref=nb_sb_noss_1

I wound up choosing: Super Lube 92003 Silicone Lubricating Grease with PTFE, 3 oz Tube, Translucent White

RE: Can I use these lubricants of my MK2 or 3?

If you read the fine print of Superlube, it as a base oil of 8 ...

Your doing it again!, half the information, Yes it has a viscosity of 8 at 100 Deg C...

Also you will find that the bearings PRUSA supply do not have grease shields, just dust shields, if they were grease shields you would not be able to see a gap.

Also on the MISUMI specification I see no mention of a grease seal?, just a dust proof seal - both ends with adhesive, but do grant that it is a much better fit around the shaft, but this is no grease shield.

The oil boundary film does not get pushed out of the way by the balls first pass since the bearing does not actually make contact with the rod, this is the whole point of a lubricant, but what it does do is evaporate and diminish which is why it needs to be replaced often, as I have already stated, before every print and possibly during extremely long prints, systems with oil baths or circulating oil apart from lubrication are there mainly to remove heat and you will always find these systems in highly loaded fast operating bearings, such as on belt driven high volume, high pressure, high speed powder transfer blowers.

Types of Bearing Lubricants

Oil: Both petroleum based and synthetic oils are available. Examples of synthetic oils are silicone, diesters, PAO’s, and fluorinated compounds. Bearings lubricated with oil will exhibit less start up and running torque and have higher speed capability. Oils are subject to evaporative losses so there service life in a bearing is less than grease. Miniature and instrument bearings are often only lubricated once for the life of the bearing, making the choice of lubricant critical. Larger bearings are subject to re- lubrication as part of the machinery maintenance cycle. These bearings are often lubricated via oil recirculation systems that are designed into the machinery or equipment. Temperature range, viscosity, evaporative rate are key characteristics to consider when selecting an oil.

Grease: Grease consists of a base oil with a thickener added. These thickeners consist primarily of metal soaps (lithium, sodium, aluminum, and calcium), organic (ureas), or inorganic compounds. While these thickeners greatly influence the characteristics of the grease, the lubricating properties of the grease are attributable to its base oil. In addition, grease can contain additives that improve its performance. Additive types include antioxidant, anticorrosion, anti-wear, fillers, fortifiers, and extreme pressure fortifiers. Temperature range, base oil viscosity, and stiffness or penetration level are key characteristics to consider when selecting a grease. Most greases used in rolling element bearings are NLGI grade 2

Anyway I've had enough of this discussion and am just trying to make people aware of the fact that stating a #2 grease is required is not as straightforward as it seems, more information needs to be given to match the grease to the application it is to be used for, and that there are alternatives, each with their pro's and con's.

Normal people believe that if it is not broke, do not fix it. Engineers believe that if it is not broke, it does not have enough features yet.

RE: Can I use these lubricants of my MK2 or 3?

I'm reading through all of these, keeping track for that inevitable day when I have to dig in for an upgrade. I appreciate all the info either way.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan

RE: Can I use these lubricants of my MK2 or 3?

If you use a Lithium #2 grease, go for one with a low base oil viscosity. The Mogul LV 2 EP Prusa recommend has a base oil viscosity of 50, Superlube has a base oil viscosity of 65, but also contains PTFE which can build up, although I've yet to here anyone on these forums report bearing failures for this reason.

Talk about the pot calling the kettle black ... lol.

RE: Can I use these lubricants of my MK2 or 3?

Edit time ran out ...

In forums I think I get lazy: I call PLA PLA regardless of actual composition. How many types of PLA are there, anyway? If I paid attention to all of the minutia regarding the subjects we discuss my posts would be 20 times longer, contain less real information, and probably ignored TLDR wise.

Bottom line is I would not use 3-in-1 oil because it drips off, doesn't lubricate well, and is pretty messy and hard to remove after it drips onto the bed. I did use something similar as a rescue lube with my OEM bearings when they started seizing... but that was temporary until I installed new bearings. That's why I suggest grease. Misumi says #2 grease and lists some options in their catalog. Lubriplate and Lithese were mentioned when I was talking to them, so occasionally I parrot those brands. I use Superlube 21030, and I mention it because it is available everywhere, too. I think the important thing is to stress grease is needed. In cases where printers are crashing (seizing), most are built with no lubrication because users believe Prusa's claim they ship pre-oiled with lubricant; which most of us know is blatantly misleading, if not downright false.

As to which lubricant is best? I am NOT a mechanical engineer. I am not a chemist. I am not a grease expert. We all have access to a lot of documentation on such things, but at the end of the day: do the bearings in your printer seize, or not?

RE: Can I use these lubricants of my MK2 or 3?

@tim.

It finally happened, I printed and printed and did not oil my X axis rods enough.

Looks like I'm now a grease convert, oils great, but you need to keep re-oiling regularly.

Luckily I have a set of misumi rods and bearings sitting in a box under the table 😊

But first I'm going to rotate the existing scored rod and lubricate using that steering box grease I think will be good.

Nothing to loose.

Better order some more cable ties because a strip down results in a lot of cutting them off and refitting again.

Normal people believe that if it is not broke, do not fix it. Engineers believe that if it is not broke, it does not have enough features yet.

RE: Can I use these lubricants of my MK2 or 3?

X anz Z rebuilt, only the bottom X bearing was rough and left a single score mark on the shaft, the two top ones were fine, Z bearings were a little dry, but nothing scoring.

The grease is being left all over the shafts, and I keep wiping off the buildup at the ends, pretty soon, there will be no excess left inside the bearings.

Put grease on the Y axis rods and it has picked up some of it into the bearings.

Normal people believe that if it is not broke, do not fix it. Engineers believe that if it is not broke, it does not have enough features yet.

RE: Can I use these lubricants of my MK2 or 3?

One point I don't see mentioned often: the grease injectors you can find on Thingiverse are great,

They force grease into the ball races under a little pressure.

Just print the injector - and cap - before you tear down your printer.

RE: Can I use these lubricants of my MK2 or 3?

@robert-rmm200

There should be no problem lubricating Delrin (Acetal) with a mineral oil based grease like most light Lithium grease has. It is actually preferable to a dry surface. The only consideration I'd have is keeping your printer clean and free from abrasive grit whether you use lubricant or not.

Mechanical Design since June 1973 3D Printing since November 2016 😀

RE: Can I use these lubricants of my MK2 or 3?

@robert-rmm200

There should be no problem lubricating Delrin (Acetal) with a mineral oil based grease like most light Lithium grease has. It is actually preferable to a dry surface. The only consideration I'd have is keeping your printer clean and free from abrasive grit whether you use lubricant or not.

The only Delrin in our machines is the trapezoidal nut. Has anyone ever had a problem with them from being dry or wearing out?

RE: Can I use these lubricants of my MK2 or 3?

Don't let any form of lubrication touch the lead screws. It will damage the Delrin trapezoidal nuts.

People should not worry about lubricant "touching" the lead screws and damaging the Delrin (acetal) nuts. The life expectancy of the nuts increases with lubricant such as a light Lithium mineral oil based lubricant.

Machine Design: Wherever possible, you should lubricate plastic components to reduce friction and wear, and increase component life. Tests show that lubricated plastic sliding bearings last up to five times longer than nonlubricated ones.

Mechanical Design since June 1973 3D Printing since November 2016 😀