Re: CAD models for MK3 parts

Hi everyone,

just finished building the SolidWorks Assembly and I am uploading the assembly in different formats for you all to have an easier time in the future.

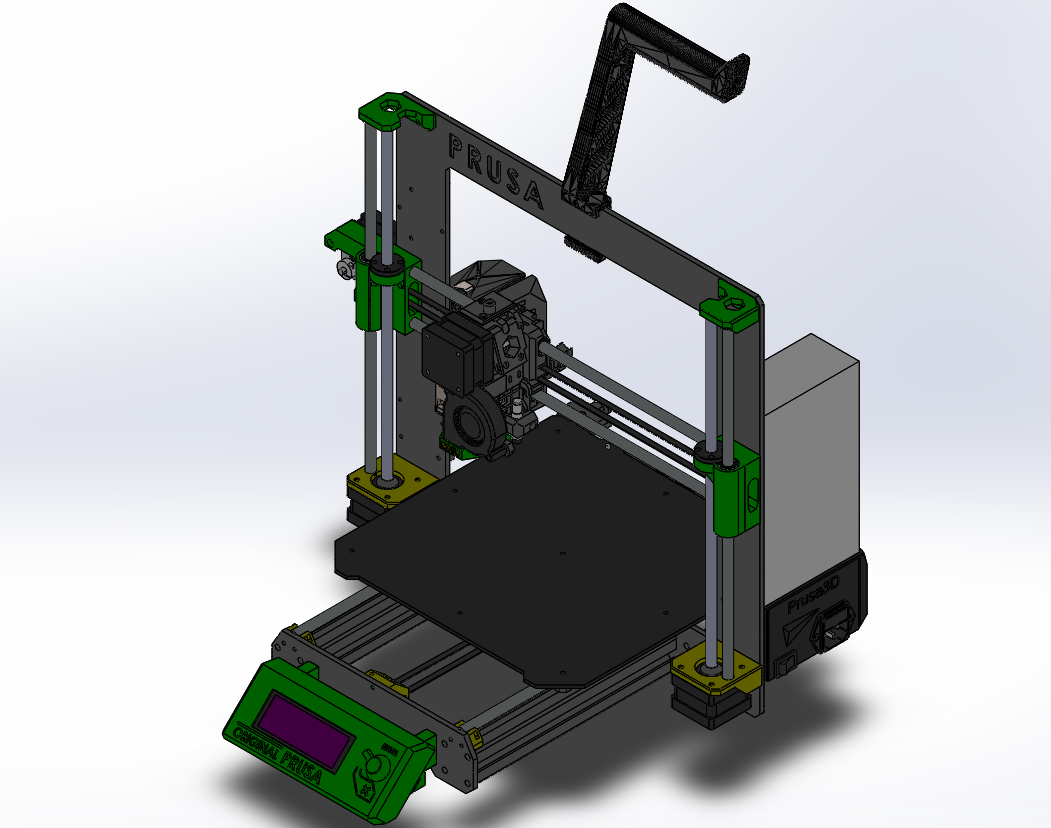

Here is a screenshot of the completed Assembly:

Link to the Github is here:

https://github.com/jzkmath/Original-Prusa-i3/tree/MK3/Printed-Parts

Link to the GrabCAD is here:

https://grabcad.com/library/prusa-i3-mk3-solidworks-1

If you want to download the STEP of the full assembly, go to GrabCAD. It is too large for Github!

Hope everyone can make good use of these files!

-Jonathan Kayne

Jonathan Kayne, KM4CFT

Virginia Tech Class of 2021 - Electrical EngineeringCreator of the CFT1 Transceiver"I am always thinking about making. My future begins when I wake up and see the light." - Miles Davis

Re: CAD models for MK3 parts

Hi Jonathan,

good job! And thanks a lot for sharing! I still can't open some step files (like x-end-idler), but the solidworks parts are fine for me. It seems Solidworks has the more tolerant step import.

BTW can you describe how exactly you managed to generate the non-faceted step files? I did it via Freecad (in Freecad: open scad file (having told Freecad first where the openscad executable is), then export step), but that keeps the cylinder facets exactly as specified by the $fn parameter in the scad file. How did you get rid of those?

And BTW2 out of curiosity does Solidworks give you editable geometry like dimensioned sketches or just fixed imported geometry? I would expect the latter, but who knows... maybe they have a clever import algorithm that can detect geometry elements and reconstruct an editable model tree. After all, Solidworks is at least twice as expensive as my Alibre Design...

And BTW3 has anyone plans to change something specific?

I intend to try the volcano hotend in order to get large, less detailed stuff faster. If one does not want the nozzle to be 8.5 mm lower (because of the longer heating zone), this means the hotend (and maybe extruder as well) has to be shifted up by that amount, which is a massive rework on the most complex parts on this printer. AFAIK Stephan is working on that (separate thread in "improvements"), maybe I try a quick fix first to see if quality suffers too much or if it would be still OK with the volcano before attempting a full redesign of the extruder.

- Martin

- Martin

Re: CAD models for MK3 parts

Jonathan,

Like many I've struggled with getting usable STEP files from the SCAD's so I very much appreciate the effort you have put into this.

Thank you!

Alfred

Re: CAD models for MK3 parts

...

And BTW2 out of curiosity does Solidworks give you editable geometry like dimensioned sketches or just fixed imported geometry? I would expect the latter, but who knows... maybe they have a clever import algorithm that can detect geometry elements and reconstruct an editable model tree. After all, Solidworks is at least twice as expensive as my Alibre Design...

in SWX (Solidworks) you get fixed geometry. SWX as a "feature detect" feature, which tries to recognize Holes , extrution etc. but with mixed results.

EDIT: in SWX you also have tool sto change the imported part, so in a way you can edit them.

Re: CAD models for MK3 parts

Hi Jonathan,

good job! And thanks a lot for sharing! I still can't open some step files (like x-end-idler), but the solidworks parts are fine for me. It seems Solidworks has the more tolerant step import.

BTW can you describe how exactly you managed to generate the non-faceted step files? I did it via Freecad (in Freecad: open scad file (having told Freecad first where the openscad executable is), then export step), but that keeps the cylinder facets exactly as specified by the $fn parameter in the scad file. How did you get rid of those?

And BTW2 out of curiosity does Solidworks give you editable geometry like dimensioned sketches or just fixed imported geometry? I would expect the latter, but who knows... maybe they have a clever import algorithm that can detect geometry elements and reconstruct an editable model tree. After all, Solidworks is at least twice as expensive as my Alibre Design...

And BTW3 has anyone plans to change something specific?

I intend to try the volcano hotend in order to get large, less detailed stuff faster. If one does not want the nozzle to be 8.5 mm lower (because of the longer heating zone), this means the hotend (and maybe extruder as well) has to be shifted up by that amount, which is a massive rework on the most complex parts on this printer. AFAIK Stephan is working on that (separate thread in "improvements"), maybe I try a quick fix first to see if quality suffers too much or if it would be still OK with the volcano before attempting a full redesign of the extruder.

- Martin

When I imported to freeCAD, the model usually had all the cut geometry left in, so I had to manually select each body and perform the Boolean difference command (in the openscad menu of freeCAD)

I don't actually know why it didn't include the facets in the STEP model, but maybe it is a new feature or something? I installed freeCAD only a few days ago...

I still would like to have the einsy base model in a proper step format, as the one in SolidWorks is only converted from the STL.

When I imported to SolidWorks, it had the editable geometry, but a solid body. All I really needed was the ability for SolidWorks to recognise surfaces and circular geometry for the concentric mates and coincident mates.

-Jonathan

Jonathan Kayne, KM4CFT

Virginia Tech Class of 2021 - Electrical EngineeringCreator of the CFT1 Transceiver"I am always thinking about making. My future begins when I wake up and see the light." - Miles Davis

Re: CAD models for MK3 parts

Hi Jonathan,

good job! And thanks a lot for sharing! I still can't open some step files (like x-end-idler), but the solidworks parts are fine for me. It seems Solidworks has the more tolerant step import.

BTW can you describe how exactly you managed to generate the non-faceted step files? I did it via Freecad (in Freecad: open scad file (having told Freecad first where the openscad executable is), then export step), but that keeps the cylinder facets exactly as specified by the $fn parameter in the scad file. How did you get rid of those?

And BTW2 out of curiosity does Solidworks give you editable geometry like dimensioned sketches or just fixed imported geometry? I would expect the latter, but who knows... maybe they have a clever import algorithm that can detect geometry elements and reconstruct an editable model tree. After all, Solidworks is at least twice as expensive as my Alibre Design...

And BTW3 has anyone plans to change something specific?

I intend to try the volcano hotend in order to get large, less detailed stuff faster. If one does not want the nozzle to be 8.5 mm lower (because of the longer heating zone), this means the hotend (and maybe extruder as well) has to be shifted up by that amount, which is a massive rework on the most complex parts on this printer. AFAIK Stephan is working on that (separate thread in "improvements"), maybe I try a quick fix first to see if quality suffers too much or if it would be still OK with the volcano before attempting a full redesign of the extruder.

- Martin

BTW

I just did a test with z-axis-top

Starting from OpenSCAD

- open the file and press F6 to build the part

- move to the editor pane on the left and delete the feature at the end of the code, z_top_left(); because this is just a mirror of the right and you don't need to bother exporting it.

- just a little higher in the code, in the module z_top_right() look for the three lines starting with //version and remove those. They are the revision letter of the part and add considerable complexity to the geometry.

press F6 to build the part again

Export as .csg

open the .csg file in an editor and look for all text like $fn = 30, and so on, replace with $fn = 0, EXCEPT $fn = 6. Those are hexagonal pockets and they are intended to have 6 facets. The numbers for $fn range from about 10 to 100 and typical are 15,30,50,60,80

- save the.csg file

FreeCAD

in FreeCAD you have to select OpenSCAD as the mode from a dropdown list in the middle of the menu. On my version .16 in Linux this menu stated "=> Start" when I first launched the software. On Windows I had to use a settings menu to point FreeCAD to the OpenSCAD executable

Import/open the .csg file and wait for it to build.

There is a tree on the left side and I select the item below the top level filename. In the case of z-axis-top this feature is called "difference"

when you select this all the geometry on the viewing window should highlight.

With this object selected, file/export as .STEP.

I opened in OnShape to verify this file is OK. it seemed OK but other experience tells me there might be some small defects in the faces. Solidworks will probably be able to heal them automatically with its import repair features.

BTW2

Solidworks geometry will not have the history but it is totally editable from the solid object going forward

BTW3

I might try a titan extruder from E3D which would mean an entirely new mechanism on the carriage or else simply try for improvements in utility. I don't have my printer yet so .. hard to predict ; )

The main thing I wish to do is make an enclosure for the printer.

Re: CAD models for MK3 parts

Great job and effort!

I'm somewhat new to Github. In Github...can you download just the entire .stl directory or do you need to download each individual file in the directory?

LCD knob?

Cheers

MK3 Kit, Designed, built 4x4 CNC Plasma Cutting Table, Motorcycles Bigdogbro's Adventures

http://www.youtube.com/channel/UC5djrxBeeOKB9_6rHnn6G8A

Re: CAD models for MK3 parts

Great job and effort!

I'm somewhat new to Github. In Github...can you download just the entire .stl directory or do you need to download each individual file in the directory?

LCD knob?

Cheers

Go to

https://github.com/jzkmath/Original-Prusa-i3/tree/MK3

There should be a green download button.

Re: CAD models for MK3 parts

Got it! A big thanks.

The knob .stl is something I can easily generate.

MK3 Kit, Designed, built 4x4 CNC Plasma Cutting Table, Motorcycles Bigdogbro's Adventures

http://www.youtube.com/channel/UC5djrxBeeOKB9_6rHnn6G8A

Re: CAD models for MK3 parts

Got it! A big thanks.

The first link was the wrong branch, fixed now.

Re: CAD models for MK3 parts

Thank you very much for a really good job 😎

EDIT:

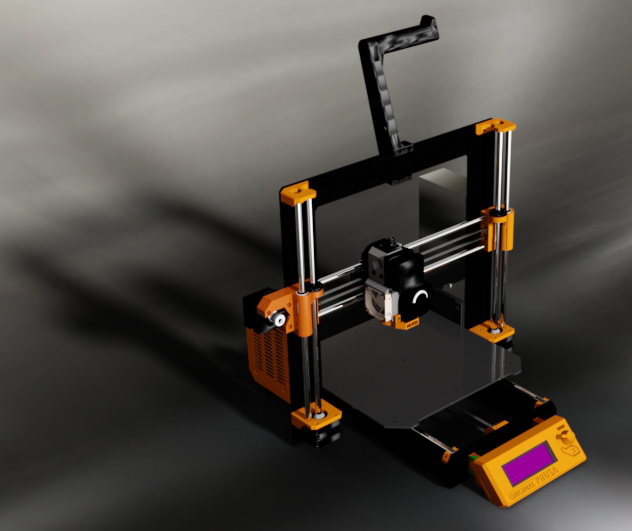

STEP-files imported and converted in Autodesk Inventor, saved, then imported to Autodesk Showcase 😎

Thank you jzkmath!

Prusa i3 MK3.png

Wow. That render looks beautiful!

Jonathan Kayne, KM4CFT

Virginia Tech Class of 2021 - Electrical EngineeringCreator of the CFT1 Transceiver"I am always thinking about making. My future begins when I wake up and see the light." - Miles Davis

Re: CAD models for MK3 parts

I still want to properly import the OpenSCAD file into FreeCAD and convert to a STEP.

When I import into FreeCAD, I get the error "unsupported function: resize".

Can someone help me with this?

Thanks!

Jonathan Kayne, KM4CFT

Virginia Tech Class of 2021 - Electrical EngineeringCreator of the CFT1 Transceiver"I am always thinking about making. My future begins when I wake up and see the light." - Miles Davis

Re: CAD models for MK3 parts

Jonathan,

I don't quite get the point. You have all files converted to step and imported to solidworks, so you are at 100% already.

Which openscad file do you mean? Also I don't quite see the point of bothering with FreeCAD if you have access to a SWX license.

- Martin

- Martin

Re: CAD models for MK3 parts

Jonathan,

I don't quite get the point. You have all files converted to step and imported to solidworks, so you are at 100% already.

Which openscad file do you mean? Also I don't quite see the point of bothering with FreeCAD if you have access to a SWX license.

- Martin

The Einsy-base file is still basically an STL put as a SolidWorks file.

I guess you are right though....

I actually just made another version that has all the hardware installed too...

Jonathan Kayne, KM4CFT

Virginia Tech Class of 2021 - Electrical EngineeringCreator of the CFT1 Transceiver"I am always thinking about making. My future begins when I wake up and see the light." - Miles Davis

Re: CAD models for MK3 parts

This episode nicely illustrates a serious problem with open source mechanical design:

- there is no free CAD software

- there is not even a file format for exchanging designs

OpenSCAD and FreeCAD are more proofs of concept than anything I'd voluntarily work with. Solidworks seems popular here but is $4k.

STL, Step, Iges etc are more or less read-only formats, unsuitable for further modifications.

So if I want to do a significant rework (anything more than a chamfer here or hole there), I'll have to reverse engineer the design. Compare this to software development...

- Martin

- Martin

Re: CAD models for MK3 parts

This episode nicely illustrates a serious problem with open source mechanical design:

- there is no free CAD software

- there is not even a file format for exchanging designs

Fusion360 is free for hobbyists.

The risk of course is locking up all your design work in the F360 cloud and taking the chance that Autodesk may someday change their mind about the "free for hobbyists" policy. You can export your F360 designs and save them on your computer, but might have to buy a commercial package if F360 isn't free anymore.

Re: CAD models for MK3 parts

This episode nicely illustrates a serious problem with open source mechanical design:

- there is no free CAD software

- there is not even a file format for exchanging designs

OpenSCAD and FreeCAD are more proofs of concept than anything I'd voluntarily work with. Solidworks seems popular here but is $4k.

STL, Step, Iges etc are more or less read-only formats, unsuitable for further modifications.

So if I want to do a significant rework (anything more than a chamfer here or hole there), I'll have to reverse engineer the design. Compare this to software development...

- Martin

I'm not sure if that is true with step or iges, but definitely STL.

Also, fusion360 is free for hobbyists, and honestly at the point where you would have to pay for it, you are probably in the financial position to buy SolidWorks anyways.

What surprises me more is that openscad doesn't export step in the first place. It's a code that literally gives coordinates, so I am surprised the lack of compatibility with other parametric software.

Jonathan Kayne, KM4CFT

Virginia Tech Class of 2021 - Electrical EngineeringCreator of the CFT1 Transceiver"I am always thinking about making. My future begins when I wake up and see the light." - Miles Davis

Re: CAD models for MK3 parts

Did anybody find the files for the spring sheet ?

I was thinking making my own with a thicker sheet because with big prints the sheet is lifting( 👿 ) and i want something stiffer

Re: CAD models for MK3 parts

Did anybody find the files for the spring sheet ?

I was thinking making my own with a thicker sheet because with big prints the sheet is lifting( 👿 ) and i want something stiffer

It should be in the Github. I didn't include it in the SolidWorks assembly because I didn't know the thickness, and it seemed pointless to add.

Should be here btw:

https://github.com/prusa3d/Heatbed_MK52_magnetic

Jonathan Kayne, KM4CFT

Virginia Tech Class of 2021 - Electrical EngineeringCreator of the CFT1 Transceiver"I am always thinking about making. My future begins when I wake up and see the light." - Miles Davis