Bridge Infill tearing

Hi,

Im having trouble with my bridge infill "tearing" at the edges

Im running prusa PLA, default temps, 0.30mm layer height - with a modified draft mk3 profile.

10% cubic infill -

with the following speeds:

Perimeters 100

Small Perimeters 50

External Perimeters 70

Infill 250

Solid Infill 250

Top Solid Infill 100

Support material 100

Bridges 60

gap fill 80.

Am i running the infill speeds too fast?

Thanks!

Sam.

RE: Bridge Infill tearing

Those speeds are much too fast. The E3D V6 hotend used in the Prusa i3 Mk3 has a rated maximum volumetric rate of 15mm^3/s. In reality, it's closer to 11.5mm^3/s, depending on the filament and parameters you're printing with. In any case, there is a finite limit on the amount of filament that the hotend can melt and move reliably. This is measured in cubic centimeters per-second (mm^3/s). In PrusaSlicer, this is referred to as Maximum volumetric speed (MVS). MVS is calculated as Extrusion Width X Layer Height X Speed. Exceed this rate and you can expect extruder skips, jumps and poor inter-layer adhesion as the filament is inadequately heated before extrusion.

If you are using an extrusion width of 0.48mm (120% of nozzle size) and layer heights of 0.30mm, you'll want to keep speeds below roughly 75mm/s to avoid over-running the extruder.

PrusaSlicer already has MVS set for PLA at 15mm^3/s and will throttle your set speeds, so you don't need to do a lot of tweaking. However, that rate is a bit high (at about 100mm/s with your settings) and may account for some of what you're seeing. In short, I'd reduce MVS for your filament down to 11.5mm^3/s (under Filament Settings->Advanced) and see if that helps.

The problem you're seeing looks like early stage pillowing, which can be caused by excessive speed (see above), temps or simply not enough top layers. You may find that successive layers fill in well enough that this isn't really a visible problem. However, I'd still slow down the volumetric rate.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan

RE: Bridge Infill tearing

Thanks Bobstro

Ill change to those settings for the next print...

and you are right - it does clean itself up with the next layers mostly (there was a 5mm wall on top of most of what I showed in the pictures... but I dont like the clunking over the bits sticking up, and Im paranoid about it knocking the print off the bed.

Cheers,

Sam.

RE: Bridge Infill tearing

Hi everyone,

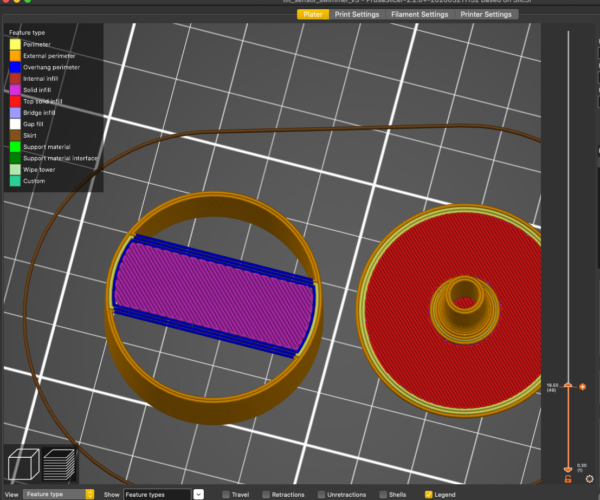

i'm new in 3d printing an just came to my first bridging problem. In the picture below, prusa slicer makes the bridge with "overhang perimeters" and "solid infill". can anyone tell me, what i have to change, that slicer treats the bridge as "bridging perimeter"? The problem in this situation is, that the overhang perimeter is printed very well, but the infill destroys the bridge. I think, that the printer should make a first layer of the bridge out of straight and parallel lines. When I change the orientation of the infill, so that they are printed as straight lines, tensed over the gap, they are printed with the speed of infill and that is to fast. I'm printing bridges with flow-ration 0.75 and 15mm/s at a 0.6 nozzle. On other parts, when slicer uses bridge-infill at the bridge, these settings are quite good. "Detecting bridging perimeters" is switched on.

Thanks!

Alex

RE: Bridge Infill tearing

Could you post your project file please. File>Save As in Prusa Slicer will save a .3mf file. The 3mf file contains the model(s) and all your print settings. It allows us to match your slice and check the previews for issues and allows tweaking things on the fly. Basically it makes it much easier to debug this sort of stuff 🙂 You will need to zip the 3mf up though as the forum only accepts a limited type of files.

Just zip it and use the attach file button to upload it.

RE: Bridge Infill tearing

nice, thanks for the fast reaction. here comes the zip file.

RE: Bridge Infill tearing

Ok thanks for the project file. That allowed me to see what was going on.

I couldn't figure out why the infill it was using wasnt being picked up as bridging infill. That infill is coloured a light blue on the preview and uses the bridging settings for flow and speed etc rather than the normal infill setting it applies when not bridged. I suspect that it will print fine side to side once it detects it correctly as bridging without the need to alter the angle in the settings.

The reason its not treating it as bridging is you had your bottom layers set to 0. No bottom layers no bridging. Once I enabled at least 1 bottom layer it picked it up.

I have attached a modified version of your project with the changes. I did alter the angle to print the bridge across the full length like you wanted but that might be too far for the MK3 cooling so you might want to change it back to auto which will print it side to side along the narrow distance. As I altered the angle I also had to set the angle of the normal infill to put it at 90 degrees to the bridge as it wanted to lay it the same direction on auto. Thats down to the fact that the bridge is the bottom layer and the top is top infill and they would both start at the same angle before they start alternating.

Anyway have a play with the project and try different settings with prints if you have the time and filament. It a good way of getting a feel for what will work in practice. The preview is a good start and should always be checked but there's no substitute for real world testing 🙂

RE: Bridge Infill tearing

@neophyl

nice thanks a lot man! it worked and the result is satisfying, too. that the bridging is dependig to the bottom layer never occured to me. great!