Bent Hot End

I change nozzles fairly often on my MK3S, and it's caught up to me. As you can see from the attached photos, the heat block is no longer aligned properly with the upper cooling fin assembly. I'm wondering what a good way to repair this is. When heated with a heat gun, the heat block rotates fairly easily, but I can't tell what is rotating -- I think it is rotating about the tube connecting the heat block to the cooling fins, but the tube may be rotating in the cooling fins. Is that tube plastic or metal?

I think this happened because the nozzle was up against the heat block, when I was trying to loosen it. I know there is supposed to be a gap there, but there are torque specs for tightening the nozzle. How do you get it to tighten to spec if it's not bottomed out? Does this imply that the threaded insert at the upper end of the heat block is not in far enough? There was some plastic that flowed out onto the top of the hot end, as seen in the 0002 image. Does that occur if the nozzle isn't bottomed out against the upper threaded insert? If the insert is not in far enough, how do I thread it farther in?

Best Answer by Neophyl:

That bent part is the heat break. You cant repair it, you will need a replacement. As for bottoming out and tightening, yes if your nozzle screws all the way into the heat block then your heatbreak is not screwed far enough in. If it isn't and does not meet the nozzle then you wont get a seal and guess what, plastic leaks up and down the threads . Giving you that mess pictured on top of the heatblock in your pics and all the other burnt leaked plastic that's covering everything.

Once you buy a replacement please study the diagrams of how its all assembled and put it together properly. Otherwise you are going to be right back here again.

When you do receive a new one and have cleaned off ALL the plastic out of the threads and the nozzle etc, you screw the nozzle in first, making sure to leave the approx 1mm gap. Then you can screw the heatbreak in to meet it and do it up finger tight. Then that assembly can be screwed into the heatsink (with the proper amount of high temp grease to aid thermal transfer.

Then it all goes back in the printer and you can then do the hot tighten at 280-285 to the torque specs to get a good seal between the nozzle and heatbreak. That's why you have to clean all the plastic out and make sure the surfaces on the nozzle and heatbreak are perfectly smooth and flat so they can seal together.

RE:

That bent part is the heat break. You cant repair it, you will need a replacement. As for bottoming out and tightening, yes if your nozzle screws all the way into the heat block then your heatbreak is not screwed far enough in. If it isn't and does not meet the nozzle then you wont get a seal and guess what, plastic leaks up and down the threads . Giving you that mess pictured on top of the heatblock in your pics and all the other burnt leaked plastic that's covering everything.

Once you buy a replacement please study the diagrams of how its all assembled and put it together properly. Otherwise you are going to be right back here again.

When you do receive a new one and have cleaned off ALL the plastic out of the threads and the nozzle etc, you screw the nozzle in first, making sure to leave the approx 1mm gap. Then you can screw the heatbreak in to meet it and do it up finger tight. Then that assembly can be screwed into the heatsink (with the proper amount of high temp grease to aid thermal transfer.

Then it all goes back in the printer and you can then do the hot tighten at 280-285 to the torque specs to get a good seal between the nozzle and heatbreak. That's why you have to clean all the plastic out and make sure the surfaces on the nozzle and heatbreak are perfectly smooth and flat so they can seal together.

RE: Bent Hot End

Better order a new hotend. They're not very expensive.

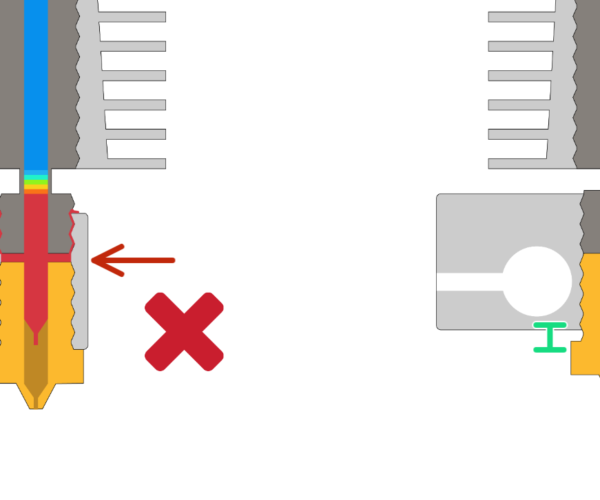

Neophyl gave you the verbal description how the nozzle needs to be assembled vis-a-vis the heatbreak and the heater block. Here's a visual.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: Bent Hot End

Better order a new hotend. They're not very expensive.

`

^^^^^^ What Fuchar said. Swap out the hot end with a new one, then rebuild the old one and put it aside for later. It never hurts to have a hot end in reserve.

Cheers

-Bob

Prusa I3 Mk2 kit upgraded to Mk2.5s, Ender3 with many mods, Prusa Mini kit with Bondtech heat break, Prusa I3 Mk3s+ kit

RE: Bent Hot End

Thanks all for the info and tips.

That bent part is the heat break. You cant repair it, you will need a replacement.

<snip>

When you do receive a new one and have cleaned off ALL the plastic out of the threads and the nozzle etc, you screw the nozzle in first, making sure to leave the approx 1mm gap. Then you can screw the heatbreak in to meet it and do it up finger tight. Then that assembly can be screwed into the heatsink (with the proper amount of high temp grease to aid thermal transfer.

Then it all goes back in the printer and you can then do the hot tighten at 280-285 to the torque specs to get a good seal between the nozzle and heatbreak. That's why you have to clean all the plastic out and make sure the surfaces on the nozzle and heatbreak are perfectly smooth and flat so they can seal together.

Thanks. This hot-end assembly came pre-assembled in my MK3S kit. The heatbreak originally had the proper inset, but apparently as I've replaced nozzles in the couple of years since original assembly the heatbreak backed out. Is there some recommended way to keep that from happening, or to reseat it?

Also, should the heatsink rotate in the housing? Does it matter?

Posted by: @bob-2 `

Swap out the hot end with a new one, then rebuild the old one and put it aside for later. It never hurts to have a hot end in reserve.

Any tips on removing the heatbreak from the heater block and heatsink?

RE: Bent Hot End

As its already broken then heating things up (when its removed from the machine) to soften the gunked on plastic and then removing with pliers/grips is probably the easiest way.

I don't know if the instructions are still the same on Prusa's site but they used to say to rotate the heatblock to break the seal. No No no. This is extremely stupid and is what causes the heatbreak to potentially back out slightly each time its done. Just use a wrench to hold the heatblock in position to stop it turning at all and then use a socket or other tool to unscrew the nozzle. Same when replacing the nozzle. You need to secure the heatblock from rotating.

While the V6 hot end is decent it does have some design shortcomings. Its cylindrical nature means there is nothing to stop it turning. The plastic of the printer extruder in effect clamps it in position but plastic clamping onto aluminium, especially with printer tolerances is not the best idea in the world.

Some of the after market V6 compatible hot ends have some nice improvements. I particularly like the Dragon's. They have a notch in them that can be used to locate the assembly and stop it turning (although you do need to modify the print head to add a locating block to make use of that on a MK3). They also have 2 screws that go from the heatsink to the heatblock to stop that rotating too. Basically makes changing a nozzle easier.

I've changed nozzles on my original V6 hundreds of times without issues but every time you have to be careful and methodical. Since I did my last rebuild where I fitted a Dragon its easier, you don't have to worry about making mistakes as much.

RE: Bent Hot End

Hi all,

right now I am changing back from 0,25mm nozzle to 0,4mm nozzle. While cleaning the lower surface of the heat block I realized that it is "relativly" easy to turn the heat block (no nozzle installed that time). When I fit and tighten the nozzle (285°C) it is much better (1mm gap is present). Can not see any leakage but I think it was more tight when I got the printer.

Do I understand that right (provided the nozzle torque is ok and no leakage is seen), that some very limited movability is NOT an issue? Or does it just mean the torque is still to low?

How is the "number 2 - not sure about the name, "heat break"?" connected to the tube coming from above (point 3). Is it pressed, soldered? The tube from above looks metalic.

Could you please also explain where to use thermal grease and were not? Between heat block and "number 2 - "heat break"? Will order a new hot end assy but need to print somethng urgently.

Kind regards Harald

RE: Bent Hot End

Torque is only valuable as long as there's a gap between the nozzle and the heat block, see the diagram fuchsr posted which shows what that gap should look like.

Cheers

-Bob

Prusa I3 Mk2 kit upgraded to Mk2.5s, Ender3 with many mods, Prusa Mini kit with Bondtech heat break, Prusa I3 Mk3s+ kit

RE:

How is the "number 2 - not sure about the name, "heat break"?" connected to the tube coming from above (point 3). Is it pressed, soldered? The tube from above looks metalic.

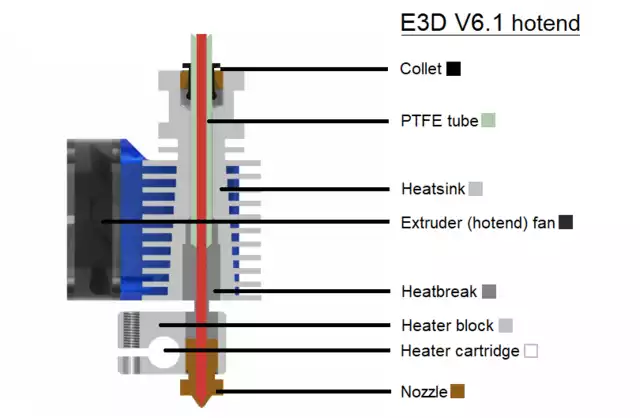

Not sure what you're referring to with number 2 and point 3 but to explain the anatomy of an E3D v6 hotend, see this picture:

As Neophyl explained, the heatbreak (the part with the thin middle piece in the middle that is bent in your situation) screws into both the heat sink (the part with the ribs) and the heater block (the part that contains nozzle, heater cartridge and thermistor). To correctly align everything you have to start with the nozzle screwed into the heater block leaving a 1mm gap, then tighten the heat break against it from above. The heat sink is then screwed onto the other end of the heatbreak. Thermal paste is only recommended for the "cold" side of the heatbreak, i.e., the side that screws into the heat sink. Once everything is assembled it is important to hot tighten the nozzle at 280 degrees.

And yes, a little rotation of the hotend assembly is not unusual as unlike the Dragon there's nothing that holds it in place. But the four components of the assembly (nozzle, heater block, heatbreak, and heat sink) should not show any movement relative to each other.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: Bent Hot End

2 and 3 are the same thing, at least on the V6 hotend used in the Mk3 series of printers. The heatbreak.

Its a machined part that is threaded on both ends and has a hole running down the middle for the filament to run through. One end screws into the heatblock. Basically the heatblock is a big lump of metal that acts like a nut to hold the nozzle firmly against the bottom of the heatbreak as well as act as a mounting point for the heater cartridge and the thermistor.

The top of the heatbreak screws into the heatsink. It is this threaded section that normally requires the thermal compound. The heatbreaks job is to have a very short thermal transition zone, which is why in your pic it is coloured going from blue to red. So the top stays cold which is why theres a heatsink radiating the heat and the paste to aid in thermal transfer.

The bottom stays hot. Heat transfer paste is NOT used on the lower section as you do not want any chance of contaminating the melted filament.

The heatbreak should screw all the way into the heatsink and stop when it reached the end of the threaded section in the heatsink. With the nozzle tightened into place there should be no rotation of the parts of the assembly relative to each other. Of course as the heatsink is cylindrical the only thing stopping the whole thing rotating once put into the printed parts is the clamping effect of those plastic parts when screwed together. Often this can be limited by the printed parts tolerances as I previously mentioned.

With the nozzle removed the heater block can rotate easily (unless gunked up with plastic from a slow leak). That is why you need to secure it with a second wrench/spanner when swapping a nozzle.

RE: Bent Hot End

the instructions are still the same on Prusa's site but they used to say to rotate the heatblock to break the seal. No No no. This is extremely stupid and is what causes the heatbreak to potentially back out slightly each time its done.

Thank you! That is what I did for a long time and I always wondered about it and if it would cause trouble. Likely the cause of my current situation.

Thanks for the suggestion of the dragon hotends. Do you use the aluminum or ceramic heatbreak version? How well does it work with PLA? I'm printing more and more high temp like nylon but still a fair amount of PLA.

Also, do you have a pointer to a .stl or design file for the modified print head?

RE: Bent Hot End

BTW, are these collets the same as the ones in the E3D V6? Mine broke when disassembling.

RE: Bent Hot End

I am not sure the micro swiss ones are the same size. They all look visually the same. I do know that the CR ones don't fit as I used to have a CR10. I'm surprised E3d don't have them listed as spares on their store but I found this https://kb-3d.com/store/e3d/47-e3d-bowden-collet-for-metal-175mm-1644688752951.html

Look for ones specifically saying V6.

My extruder is a bit of a frankenmonster. My printer was originally a MK3 but the current extruder is based off a geared Bunny and Bear one. So it still uses the original Mk3 filament sensor but with a bearing making it much more reliable. However I've redone several parts of it, so it takes a Mk3S style fan and shroud now and I made other modifications for my wiring setup as well as reinforced the pinda mount significantly. No more sagging on that.

So I had to do my own notch modification for the dragon when I swapped.

There are several on printables though such as https://www.printables.com/model/67418-dragon-hotend-adapter-phaetustrianglelab or a more extensive print https://www.printables.com/model/98335-prusa-i3-mk3s-dragon-hotend-mod-v3 there are others around.

I think it was Fuchsr posting about his that led me to try one. Had it for a year now and have had zero issues and been really happy with it.

I used the standard flow dragon core v2 heatbreak along with a plated copper heatblock.

RE: Bent Hot End

Thanks.