Bearing and hot end questions

Question 1:

Today I was doing some maintenance (mostly rebuilding as I did the MK3S to MK3S+ upgrade and life hit me like a truck and I never got my first layer cal done properly), and I popped around 4 balls out from each side (not sure how many per bearing) of the z axis rods, I looked at buying 4 new bearings from prusa but ALL 3 of the reviews say they are really bad. I started digging around and found many suggestions for Misumi bearings and rods, I looked in to them and I see some people suggesting LM8UU Misumis and others suggesting LMU8 Misumis, on Prusas site I see they sell LM8UUs of -insert whatever brand here- which leads to my question, which do I get and which rods to go with them? Or am I fine?

Question 2:

Today as I was rebuilding I noticed that the gap that Prusa suggests when changing the extruder end was not there on the one I got when I bought my MK3S, its right against the block straight from the factory (as I've never changed the hot end tip), in an attempt to rectify this I unscrewed the heat sink area from the block, I know there's thermal compound there and some did come off, I screwed it back together and figured I'd pick up a full assembly as I probably screwed myself, well they are sold out, so I'm stuck with what I have.

What do I need to do to rectify the two issues, 1. no gap between heat sink and extruder end, and 2. do I need to grab some thermal paste and redo it or am I good?

RE: Bearing and hot end questions

1. my bearings have been doing fine so far just load theme with lube first

2. if its printintg ok with no fillament coming out behind nozzle then its fine dont change it and probally best to redo thermal paste but it depends how much came off

Please help me out by downloading a model it's free and easy but really helps me out https://www.printables.com/@Hello_474427/models

RE:

I don't envision the bearing confusion/issue going away at all.

My interim conclusion is that whatever comes on the bearings when we get them from Prusa is indeed adequate for the expected life of the device under the load of normal operation.

My MK3S is over three years old and the counter is well up into the hundreds of days of use, with particularly heavy use during the peak of the pandemic. No bearing noise, no 'play' or 'slop' on the axes, no scored rods. I did not do anything to the bearings upon assembly. Every so often I will put a few drops of light synthetic machine oil on the rods, and every so many so-oftens I will rub some Superlube on the rods.

If the lube was actually sub-par, I would suspect that we would have countless tales of machines self-destructing and melting down by now.

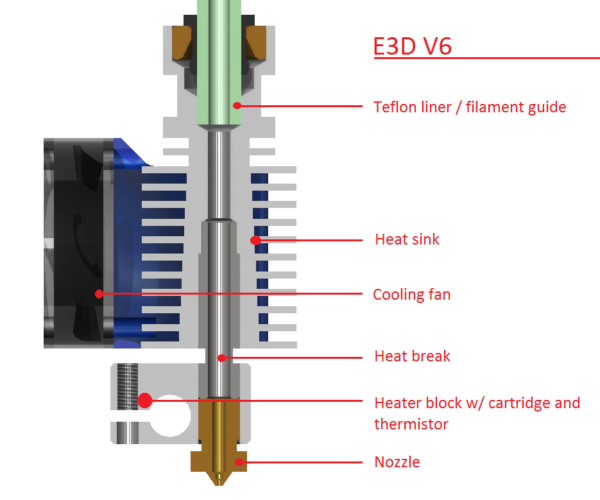

Now, as to that gap between the nozzle and the heat block, if you look at the diagram of the hot end, you will see that the important thing is that the heat break and the nozzle are in intimate contact within the heat block. That particular surface is where the tight seal must be.

If that mating surface is indeed tight, but the nozzle-heat break are positioned such that the gap is smaller or not visible, it should still work. If it is indeed not leaking, I would put it in the 'ain't broke, don't fix it' category. If it starts to leak molten filament, even slightly, I would suggest disassembling it and repositioning things as shown in the diagram.

I've never had to use any thermal compound when working with the Prusa hot end. (I have when rebuilding the print core for another brand of printer.) If you do use it, be sure it's rated for high temperature. Profiles for some filaments can run the hot end around 300 degrees C!

I really think many folks underestimate the amount of pressure that is built up in the hot end, as the extruder forces the molten filament through a fractional-mm oriface. If there's any place for that filament to go (as in along threaded parts) it will find it and leak out. One crumb of debris or scorched filament between the bottom of the heat break and the top of the nozzle can cause that kind of leak.