Re: 1st layer problems - in depth look at software PINDA problems (and solutions!)

The pinda is only utilized during mesh leveling. After the print starts, the pinda is no longer in the picture.

So to answer your question- it IS normal for the pinda to rise in temperature after you start printing (as it is heating up mostly due to the bed heat in close proximity), but it doesn't really matter.

Re: 1st layer problems - in depth look at software PINDA problems (and solutions!)

Exactly what Reid said!

PINDA and its temperature are irrelevant during print. It just matters during homing and mesh bed calibration. And because it heats up during print - be sure to WAIT for the cool down of the PINDA when you do a manual temperature calibration. The next firmware can do that for you automatically - as mentioned above.

Re: 1st layer problems - in depth look at software PINDA problems (and solutions!)

by the way: I think you arrows are wrong:) The good parts looks too fluffy for me - too high. The "bad" part is more squished, and looks better to me.:-)

But during manual calibration it is only important that you achieve the SAME quality exactly for each temperature. It does not have to be the "optimal" first layer quality but the SAME quality each time.

And if your 1st layer height changes during print, consider doing XYZ calibration again. Before that, make sure your bed is parallel/flat. Maybe use "wave washers" to flatten the bed (search forum @ff8jake found out how to do it AND wrote a fantastic octoprint plugin to display the "flatness" of your bed). If you have calibrated the hardware THEN it is time to calibrate the PINDA temperature compensation. I reached a bed deviation of 0.02mm at 60C bed temperature. Then I redid XYZ calibration, then I calibrated the PINDA once more.

For the easy to do wave washers mod and octoprint plugin: https://shop.prusa3d.com/forum/user-mods-octoprint-enclosures-nozzles--f65/-help-needed-octoprint-prushmeshmap-plugin-t15333-s120.html#p85988

And if you wonder what wave washers are: https://www.amazon.com/gp/product/B0786LYF3V/ref=oh_aui_detailpage_o05_s00?ie=UTF8&psc=1

Re: 1st layer problems - in depth look at software PINDA problems (and solutions!)

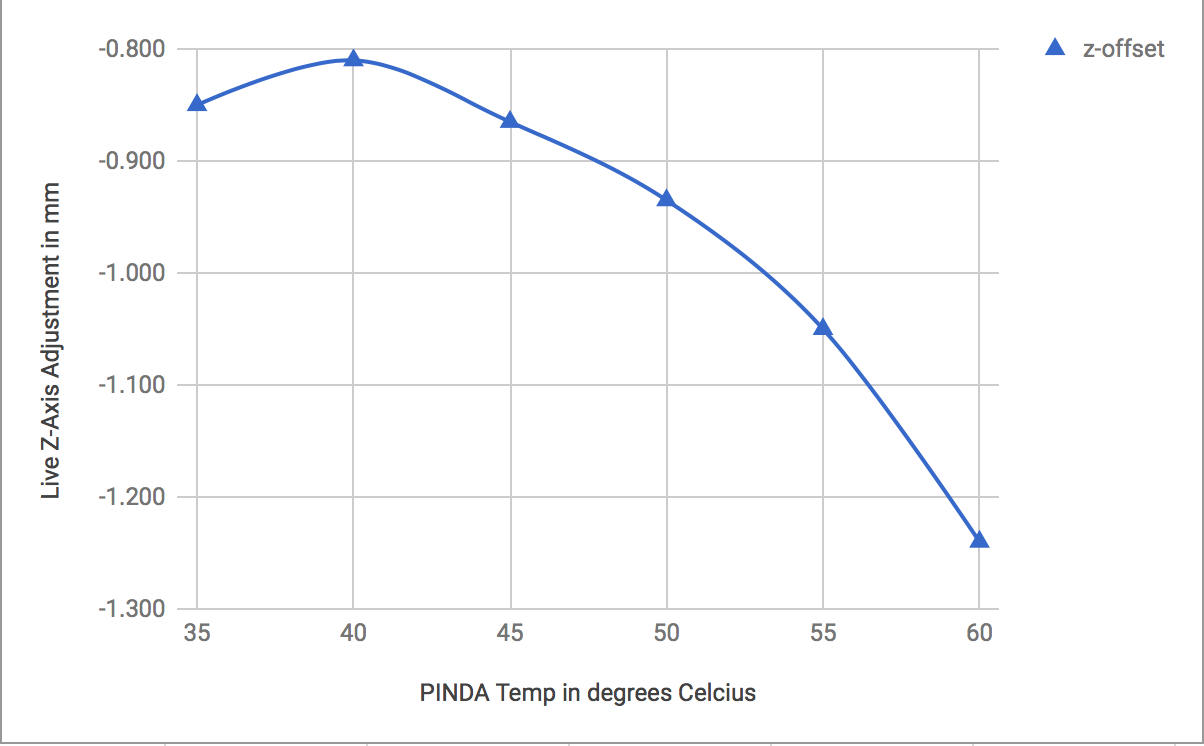

just went thru the manual calibration process over the last two days. i'm using the stock 3.2.1 firmware at the moment and i have a PINDA with a Black cable and Black tip tho i thought my printer kit fairly new so not sure why everyone else's recent ones are grey. I did a factory reset, downloaded the 1st_layer_XXC.gcode files stahl created, disabled temp calibration option, zero'd the temperature numbers using the M861 Z and verified with M861 ? and then and went about running the prints. BTW, i had issues printing the 45℃ and up files via octoprint due to an error about line 19 or something during the PINDA heatup procedure, i wish i had copied the terminal output but they worked fine when printing from the SD card. Also I had to modify the 45℃ .gcode to heat the bed to higher than 60℃ to get the PINDA warm enough to trigger the rest of the code. I think i bumped it all the way up to 80℃ and that did the trick. At any rate here's what i got:

Index Temp z-offset µm µstep

n/a 35 -0.850

0 40 -0.810 -40 -16 M861 S-16 I0

1 45 -0.865 15 6 M861 S6 I1

2 50 -0.935 85 34 M861 S34 I2

3 55 -1.050 200 80 M861 S80 I3

4 60 -1.240 390 156 M861 S156 I4

I was a bit concerned that my 35℃ Z-offset was larger than the 40℃ but then things seemed to be trending upward, or downward depending on how you look at it i guess. just to be sure after i had gone thru the whole course i re-ran the 35℃, 40℃ and 45℃ tests to be sure my values were correct. and they were.

then i entered the new µstep commands via my octoprint terminal and then verified they were saved with M861 ?. then i shut off the printer, turned it back on and checked again to ensure they had been committed to the eeprom.

so now what? i should be all calibrated with real-world values. to what should i set the Live-Z adjustment value to so i can get to the "set it and forget it" moment? 😉

i did a print lat last night after finalizing the calibration but didn't know if i should adjust again or not. i suppose i probably should have done one last single-layer print to check the squish was consistent before running my proper print and that would have been the correct course of action. and i did add stahl's day-to-day START GCODE to my Slic3r parameters so that my object would use them.

this all sound correct?

as an aside i want to thank everyone who has contributed to this thread. i had to re-read it a few times to get everything down but feel pretty good at the moment.

Re: 1st layer problems - in depth look at software PINDA problems (and solutions!)

I ran the manual calibration second time today and the results were completely different from the first time. Which got me thinking whether the calibration process is at all trustworthy. First run was a few weeks ago but there were no hardware nor firmware changes since then.

Previous values: 2, 7, 14, 66, 137

New values: 6, 19, 50, 81, 151

I guess I'll have to run it third time, wouldn't be surprised if it came up with different values once again. Slightly puzzled here.

Re: 1st layer problems - in depth look at software PINDA problems (and solutions!)

just went thru the manual calibration process over the last two days. i'm using the stock 3.2.1 firmware at the moment and i have a PINDA with a Black cable and Black tip tho i thought my printer kit fairly new so not sure why everyone else's recent ones are grey. I did a factory reset, downloaded the 1st_layer_XXC.gcode files stahl created, disabled temp calibration option, zero'd the temperature numbers using the M861 Z and verified with M861 ? and then and went about running the prints. BTW, i had issues printing the 45℃ and up files via octoprint due to an error about line 19 or something during the PINDA heatup procedure, i wish i had copied the terminal output but they worked fine when printing from the SD card. Also I had to modify the 45℃ .gcode to heat the bed to higher than 60℃ to get the PINDA warm enough to trigger the rest of the code. I think i bumped it all the way up to 80℃ and that did the trick. At any rate here's what i got:

Index Temp z-offset µm µstep

n/a 35 -0.850

0 40 -0.810 -40 -16 M861 S-16 I0

1 45 -0.865 15 6 M861 S6 I1

2 50 -0.935 85 34 M861 S34 I2

3 55 -1.050 200 80 M861 S80 I3

4 60 -1.240 390 156 M861 S156 I4

I was a bit concerned that my 35℃ Z-offset was larger than the 40℃ but then things seemed to be trending upward, or downward depending on how you look at it i guess. just to be sure after i had gone thru the whole course i re-ran the 35℃, 40℃ and 45℃ tests to be sure my values were correct. and they were.

graph.png

then i entered the new µstep commands via my octoprint terminal and then verified they were saved with M861 ?. then i shut off the printer, turned it back on and checked again to ensure they had been committed to the eeprom.

so now what? i should be all calibrated with real-world values. to what should i set the Live-Z adjustment value to so i can get to the "set it and forget it" moment? 😉

i did a print lat last night after finalizing the calibration but didn't know if i should adjust again or not. i suppose i probably should have done one last single-layer print to check the squish was consistent before running my proper print and that would have been the correct course of action. and i did add stahl's day-to-day START GCODE to my Slic3r parameters so that my object would use them.

this all sound correct?

as an aside i want to thank everyone who has contributed to this thread. i had to re-read it a few times to get everything down but feel pretty good at the moment.

That sound all very awesome. You need to enable temp. cal. in the menu after you have programmed the eeprom.

Then you set live Z to a value that is close to the value you had at 35C. Then you start your prints with a PINDA temperature of at least 35C always. Fine tune live Z as needed.

I have learned now, that each filament is a little different, what concerns live Z - so when switching spools or, types of filament - watch the first layer and fine tune live Z as needed - after that, it is repeatable:-)

Re: 1st layer problems - in depth look at software PINDA problems (and solutions!)

I ran the manual calibration second time today and the results were completely different from the first time. Which got me thinking whether the calibration process is at all trustworthy. First run was a few weeks ago but there were no hardware nor firmware changes since then.

Previous values: 2, 7, 14, 66, 137

New values: 6, 19, 50, 81, 151

I guess I'll have to run it third time, wouldn't be surprised if it came up with different values once again. Slightly puzzled here.

Hi Confusius,

I had the same experience after fiddling with wave washers on my heat bed. And updating to the 3.2.X firmwares. I finally recalibrated XYZ, did another PINDA calibration and since then I am happy again with my PINDA temperature calibration.

I guess it is only super correct for the moment - and now that we have summer, ambient is warmer, material has different temperatures and thus dimensions - we are taking um differences here:-)

Re: 1st layer problems - in depth look at software PINDA problems (and solutions!)

One thing I forgot: If you want to install my custom firmware that I linked above - you could print out my calibration-verification gcode file. It will print 6 squares for you automatically with the six different PINDA temperature levels. That way you can verify, that the EEPROM values that you found are inherently correct. You have to have temp. cal. activated of course and set live adjust z to your favorite value.

Here is the post with the GCODE file and the custom firmware

https://shop.prusa3d.com/forum/hardware-firmware-and-software-help-f64/1st-layer-problems-in-depth-look-at-software-pinda-t14815-s240.html#p88357

The change to the M860 Gcode has been approved by Prusa and it will be there in the next official firmware release

EDIT: here is the latest version of the temperature calibration verification gcode file (You need the firmware with the improved M860 Code to make that file work correctly)

Re: 1st layer problems - in depth look at software PINDA problems (and solutions!)

Hi,

How hard would it be to add a small heater with temperature sensor and feedback to force the PIND to maybe 50C or so all the time?

Re: 1st layer problems - in depth look at software PINDA problems (and solutions!)

Does this whole Pinda Auto Calibration work in the latest firmware 3.3.0 version? is the 860 solution from stahlfabrik included?

Re: 1st layer problems - in depth look at software PINDA problems (and solutions!)

Exactly what Reid said!

PINDA and its temperature are irrelevant during print. It just matters during homing and mesh bed calibration. And because it heats up during print - be sure to WAIT for the cool down of the PINDA when you do a manual temperature calibration. The next firmware can do that for you automatically - as mentioned above.

Is this implemented in the 3.3.0 firmware?

Re: 1st layer problems - in depth look at software PINDA problems (and solutions!)

Exactly what Reid said!

PINDA and its temperature are irrelevant during print. It just matters during homing and mesh bed calibration. And because it heats up during print - be sure to WAIT for the cool down of the PINDA when you do a manual temperature calibration. The next firmware can do that for you automatically - as mentioned above.

Is this implemented in the 3.3.0 firmware?

Yes! The M860 command now waits also for the PINDA to cool below the set temperature if both heaters are off. Sadly Prusa Research have forgotten to mention it in the Release Notes for 3.3.0 🙁

Re: 1st layer problems - in depth look at software PINDA problems (and solutions!)

Is this implemented in the 3.3.0 firmware?

Yes! The M860 command now waits also for the PINDA to cool below the set temperature if both heaters are off. Sadly Prusa Research have forgotten to mention it in the Release Notes for 3.3.0 🙁

Thanks for your answer. The automatic temperature calibration and Pinda now also works?

Re: 1st layer problems - in depth look at software PINDA problems (and solutions!)

[...] Yes! The M860 command now waits also for the PINDA to cool below the set temperature if both heaters are off. Sadly Prusa Research have forgotten to mention it in the Release Notes for 3.3.0 🙁

Does this mean it's a good idea to use M860 before every print with the extruder raised to ensure the PINDA temp drops before the print and again with the extruder homed to ensure the PINDA is warmed before leveling? Or is this only an issue for initial printer calibration? Reading this bit from your May 31st post makes me think we'd want to do it for every print:

A) If you want to start each print with exactly the same PINDA temperature, you have to make sure, that the PINDA is colder then the wanted start temperature, before you activate the heaters - otherwise the PINDA is way warmer than the wanted start temperature.

Thanks for all your work on this.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

Re: 1st layer problems - in depth look at software PINDA problems (and solutions!)

Yeah it totally depends.

I until now continue to use M860 S35 in a position close to bed with heaters on before a second homing and mesh bed leveling. Because I am quite confident in my temperature calibration so I only need to make sure that my pinda is in the calibration range of 35 to 60C

One could add a M860 S30 before the heaters are on. Also turn the part cooling fan on for even quicker cooldown. Yeah also a little raised from the potentially warm bed.

Then you will make it highly likely that you start at exactly 35C. Then you will not need a good temperature calibration at all:-) but the wait in between prints is longer.

You could have a look at the gcode file above for ideas how to implement the cooldown before heatup gcode. It’s all there.

Re: 1st layer problems - in depth look at software PINDA problems (and solutions!)

Yeah it totally depends.

I until now continue to use M860 S35 in a position close to bed with heaters on before a second homing and mesh bed leveling. Because I am quite confident in my temperature calibration so I only need to make sure that my pinda is in the calibration range of 35 to 60C

One could add a M860 S30 before the heaters are on. Also turn the part cooling fan on for even quicker cooldown. Yeah also a little raised from the potentially warm bed.

Then you will make it highly likely that you start at exactly 35C. Then you will not need a good temperature calibration at all:-) but the wait in between prints is longer.

You could have a look at the gcode file above for ideas how to implement the cooldown before heatup gcode. It’s all there.

A question you might be able to answer: The automatic temperature and Pinda calibration... now works in firmware 3.3.0?

Or manual calibration still necessary

Re: 1st layer problems - in depth look at software PINDA problems (and solutions!)

I like the idea of working regardless of calibration, so I like this approach. I've incorporated the "hover above heating bed" logic, and it seems to be working quite well. In your previous post, you wrote:

[...] One could add a M860 S30 before the heaters are on. Also turn the part cooling fan on for even quicker cooldown. Yeah also a little raised from the potentially warm bed.

[...] The M860 command now waits also for the PINDA to cool below the set temperature if both heaters are off. Sadly Prusa Research have forgotten to mention it in the Release Notes for 3.3.0

Any idea if the logic is present to deal with the PINDA already being below 35C? If both heaters are off and M860 is issued and temp is not 35C, does it detect that PINDA temp is already below 35C? I'd hate to have it hang at the start of jobs that start cold.

Thanks for the great info!

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

Re: 1st layer problems - in depth look at software PINDA problems (and solutions!)

I like the idea of working regardless of calibration, so I like this approach. I've incorporated the "hover above heating bed" logic, and it seems to be working quite well. In your previous post, you wrote:

[...] One could add a M860 S30 before the heaters are on. Also turn the part cooling fan on for even quicker cooldown. Yeah also a little raised from the potentially warm bed.

[...] The M860 command now waits also for the PINDA to cool below the set temperature if both heaters are off. Sadly Prusa Research have forgotten to mention it in the Release Notes for 3.3.0

Any idea if the logic is present to deal with the PINDA already being below 35C? If both heaters are off and M860 is issued and temp is not 35C, does it detect that PINDA temp is already below 35C? I'd hate to have it hang at the start of jobs that start cold.

Thanks for the great info!

Yes of course:-) if it is already below it goes right to the next command

Re: 1st layer problems - in depth look at software PINDA problems (and solutions!)

Yeah it totally depends.

I until now continue to use M860 S35 in a position close to bed with heaters on before a second homing and mesh bed leveling. Because I am quite confident in my temperature calibration so I only need to make sure that my pinda is in the calibration range of 35 to 60C

One could add a M860 S30 before the heaters are on. Also turn the part cooling fan on for even quicker cooldown. Yeah also a little raised from the potentially warm bed.

Then you will make it highly likely that you start at exactly 35C. Then you will not need a good temperature calibration at all:-) but the wait in between prints is longer.

You could have a look at the gcode file above for ideas how to implement the cooldown before heatup gcode. It’s all there.

A question you might be able to answer: The automatic temperature and Pinda calibration... now works in firmware 3.3.0?

Or manual calibration still necessary

Please define “works”:-)

To be honest- you would need to test it yourself, if it works for you. I have not done automatic calibration for months now.

Re: 1st layer problems - in depth look at software PINDA problems (and solutions!)

I have inconsistant first layer height that manual pinda temperature calibration hasn’t fixed.

I ordered a second pinda probe to experiment with, and while looking up thermistor table values in firmware I notice that analog2tempBed() is used for converting pinda thermistor temperature reading rather than the analog2tempPinda() function.

If someone is familiar with how pinda mesh bed leveling is done I’d like to read about it.

Is temperature taken before/after every mesh point?

Is measurement taken from rising or falling edge of pinda signal?