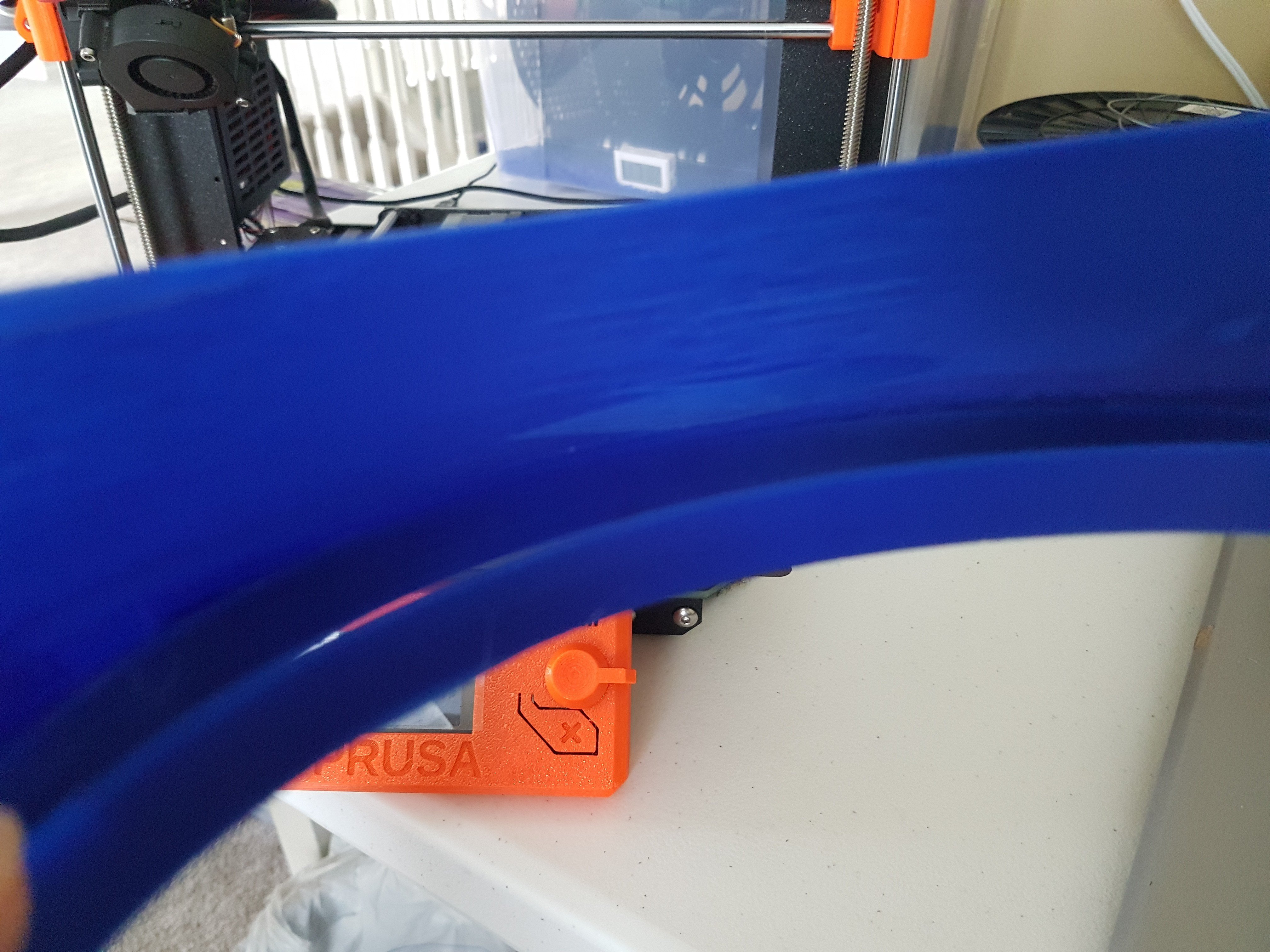

what issue is this?

i have printed this part without support as it should be, when i print it with prusament PETG it prints just fine no issues no support but when i print it with matter hacker PETG, i get this weird issue in the same area of the print i have printed a few of this using the matter hacker PETG.

is it a bridging issue, speed issue, temp?

RE: what issue is this?

i have printed this part without support as it should be, when i print it with prusament PETG it prints just fine no issues no support but when i print it with matter hacker PETG, i get this weird issue in the same area of the print i have printed a few of this using the matter hacker PETG.

is it a bridging issue, speed issue, temp?

Attachment removed

PETG is not just PETG. I can't tell from the picture, but would first change the print temperatures a little bit, maybe gradually reduce them by 5 degrees.

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.

RE: what issue is this?

Here's a tip with PETG, if the print is matt finish then your running cool and may have weak layer adhesion but looks great. In this case either you are printing too low a temperature or usually the fan setting is too high.

If your prints are glossy, then you have good temperature and cooling and your layers will be really well bonded, but you may start to get some rounding of corners and or loss of tiny detail.

If your prints are glossy and stringing a lot and the small detail is, ermm molten!, then your printing temperature is too high and you do not have enough cooling.

I cant really tell from the picture, but is that a matt finish whereas the rest is more glossy?, if this is the case, then either reduce your cooling, slow down or bump the temperature up a bit.

PETG prints best with as little cooling as you can get away with, so try fan speed settings of MIN 18 MAX 25 or even lower and adjust your temperature and speed to get good prints, this will give you strong parts as PETG needs to melt into the previous layer for best results.

There will be a slight reduction in print quality finish compared to PLA, but with the right settings this will be minimal.

I'll see if I can post my quick bridging stringing test which works well for dialling in filament settings quickly as it only takes 3 minutes to print and covers enough things to getting settings for PETG correct quickly.

Normal people believe that if it is not broke, do not fix it. Engineers believe that if it is not broke, it does not have enough features yet.

RE: what issue is this?

@chocki

please post your stringing test

RE: what issue is this?

i have printed this part without support as it should be, when i print it with prusament PETG it prints just fine no issues no support but when i print it with matter hacker PETG, i get this weird issue in the same area of the print i have printed a few of this using the matter hacker PETG.

A few observations on your settings after having printed a couple hundred of those DtM frames:

- You are printing PETG at 240C, which is well within normal guildelines. However, if you are printing in bulk and pushing a lot of filament, a bit more heat can be added. I used 250C for PETG for most prints (though with larger nozzles).

- You are printing PETG with cooling enabled full-time. For that print, I set my minimum print layer time to only turn on cooling for the visor portion (40 seconds per frame IIRC) and use a max of 30% for PETG. Use as little cooling as possible.

- You are printing PETG with Prusa's default 8mm^3/s Maximum volumetric speed. Nothing wrong with this, but if you're printing PETG at higher temps, you can likely increase this value since we're not concerned about infill on these prints.

- You are printing with a 0.4mm nozzle using 0.3mm layer heights. This is at the upper end of recommended layer heights (80% of nozzle size) and will cause difficulty with steep overhangs like the inside of that visor. For some combinations, reducing layer height for the visor portion may be necessary for good adhesion.

- You can make good use of Prusa's variable layer heights on this print. I found that using high layer heights above and below the visor pegs significantly speeded up the overall print, while a finer layer height for the visor and curved pegs produced a good quality print.

I've collected my notes on maximizing prints for PPE printing here.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan

RE: what issue is this?

Quick add-on: You want to either increase printing temps for better adhesion, cool for better finish, but not both!

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan

RE: what issue is this?

@chocki

ahh... thanks will try that out

RE: what issue is this?

@chocki

my print do seem a bit dull now that i look at it

i did not consider looking at matt/glossy finish

@bobstro

interesting point willl have to check my layer high and can we check what the layer print time is in PSlicer?

you use 30% of time of what ever the total layer print time is?

and do you often change the volumetric speed? i have never truly used it do you used it to get thicker walls or strong parts?

RE: what issue is this?

@chocki

Hi now that is a good tip to know about temp and finish.

at the moment i am printing in petg (unknown brand) but the surface finish is about the best i have ever seen. much better than some PLA

prints i have done in the past.

The printing i am doing is only one wall thick, and can be a right problem to get each layer to stick well with Pla

for me PETG is the only way to go don think i will be using much PLA in the future

RE: what issue is this?

I only use PLA for carrying out cold pulls on nozzles after purging with cleaning filament, simply don't use it at all, nearly everything I do is with PETG.

Try some tests and crank the speed up, you will see it change from gloss to matt, you can also bump the temperature up some to increase speed, but only if there are not too many hops else stringing can get a bit much and read Bobstro's notes.

I must get that test piece up with notes, missus is not working from home today so I may get a chance when I finish work before she gets home.

She complains I spend too much time with the printer and computer and not enough with her. 😉

Normal people believe that if it is not broke, do not fix it. Engineers believe that if it is not broke, it does not have enough features yet.

RE: what issue is this?

@chocki

Hi yes i think i will do more printing in PETG, I have seen many test towers for pla but not seen any for G

For me the extra cost, and slightly more difficult to print easy out weighs the change to PETG

The more i print in PETG, the printer seems to prefer it.