Warping starts after hours of printing

Hi all.

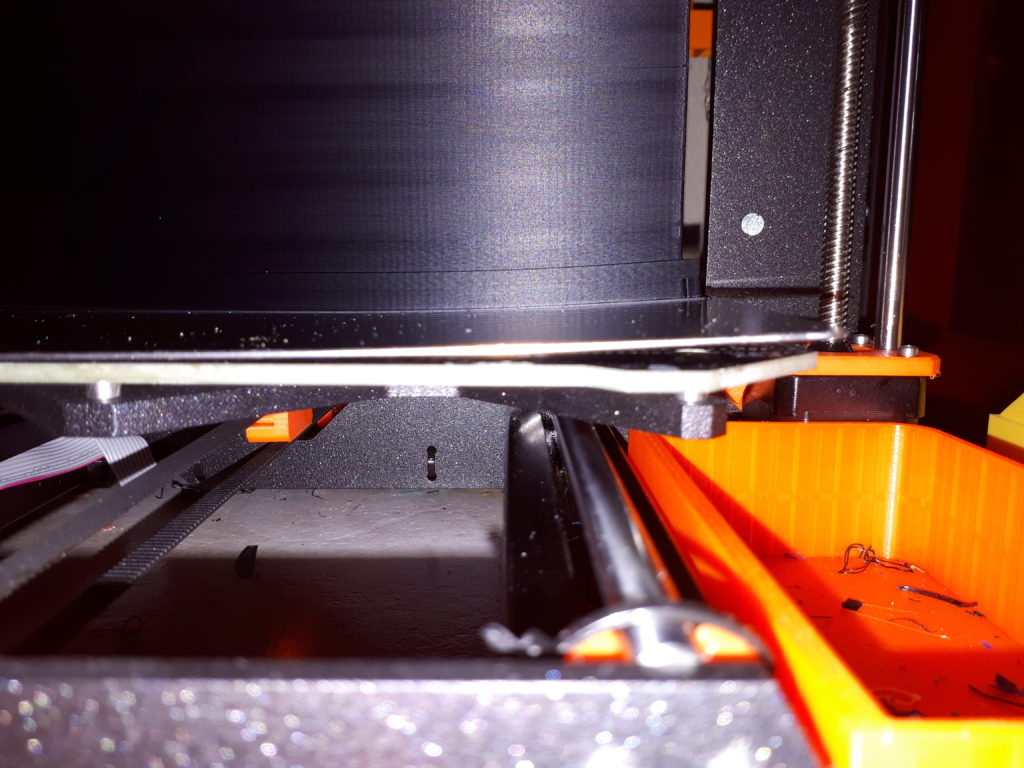

A few days ago I noticed a part of my print had started to warp after hours of it not having an issue (the first layer, and subsequent layers were fine).

Here's a video:

Does anyone know why this might have happened?

I've often had issues printing things with a large footprint but this was particularly annoying because I had to eventually stop the print. The parts were supposed to fit together and I could tell that it wouldn't have.

So, hours & hours were wasted.

When I try again, I think it's better for me to print each of the large parts individually.

Does anyone have any tips for printing things that cover largish areas of the bed? That big cube that Prusa use to show the build size never shows signs of warping 😑

Does anyone have any tips?

I've noticed in the past that parts seem to warp/detach more on the left side of the bed.

Maybe I have a temperature control issue.

Any help would be great.

Thanks

RE: Warping starts after hours of printing

Big parts warp, even PLA. Enclosures to control part cooling, adjust bed temp up to improve adhesion to aide keeping the part flat, reduce nozzle fan speed to slow part cooling, print a sheath around the part (full height skirt), etc.

RE: Warping starts after hours of printing

Is there any rational to print this huge amount of parts in one shot? A lot of movements form one part to another will take back the advantage of doing it in one shot. Nevertheless if something goes wrong in the middle of print, you can throw away everything.

What was the printing time of this combination? I would guess more than 15 hours which allows PLA to warp easily and the adhession will weaken by any additional hour of printing.

I would split at least the low parts from the high ones in two different shots

even an old man can learn new things 🙂

Standard I3 mk3s, MMU2S, Prusa Enclosure, Fusion 360, PrusaSlicer, Windows 10

PRUSA MINI+ Prusalink + Prusa Connect

RE: Warping starts after hours of printing

Large prints with sharp corners can pull from the bed on any printer and any filament. The bottom cooler layers are put in tension as more higher layers are printed. Sharp corners build up a stress concentration so are more apt to pull/curl up. One fix is better adhesion using glue stick or other adhesive treatment. Second fix is using a brim. Third fix is redesigning with rounder corners. Fourth fix is containing heat around print with an enclosure and/or hotter bed.

RE: Warping starts after hours of printing

As an FYI - a glue stick reduces PLA adhesion. A clean bed is much much better at keeping parts down.

RE: Warping starts after hours of printing

clean bed very good,

a big brim attached to part,

glue stick(with big parts and small parts i always use glue stick).

A little higher bed temp,

Cold air around your printer is bad, put a box around the printer, or a picture/photograph tent around printer, higher room temperture.

It could also be the filament.

First layer hotter and slower.

You could try 1 part at a time.

One time i used glue stick, and the steel sheet was pointing in the air, yes the glue stick worked very good.

RE: Warping starts after hours of printing

Great adhesion. That's happened to me too. And there is nothing you can really do for it but reduce part cooling as much as possible. I've turned down the print fan, even turned it off when no bridging is needed, both help to a degree. But enclosing the part is the only way to fully control cooling. A full height skirt with fan off, or an enclosure to keep the part warm. But an enclosure and PLA add to other problems unless done carefully with good planning (extruder motor can overheat and melt filament at the Bondtech gears).

RE: Warping starts after hours of printing

I think that your warp began way sooner... at height of 2-3cm already (at biggeest walls anomaly).

You have something wrong anyway - so ugly walls are not right...