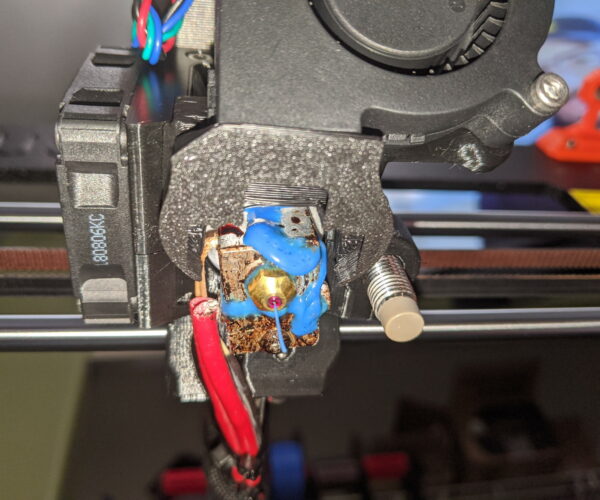

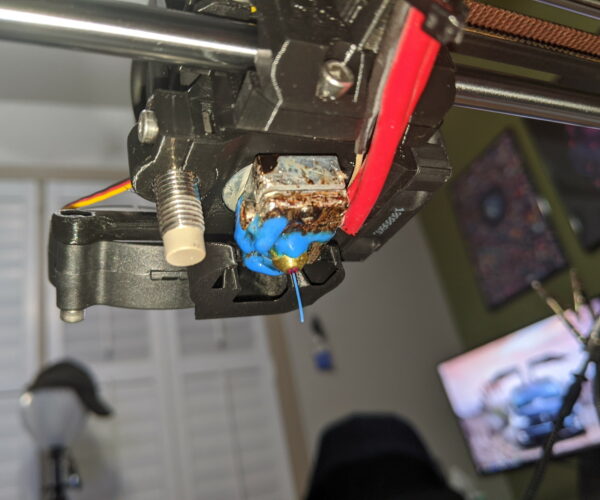

Upgraded from MK3 to MK3s + Ruby Nozzle now getting leaking

I recently purchased the upgrade from the MK3 to MK3S because I was having issues with the filament sensor not detecting certain filaments and wanted the new filament sensor design. Everything went fine. While I was at it I changed the nozzle to my new ruby nozzle (first mistake?), and my prints were coming out fine but I noticed the oozing around the heat block. Seems I didn't fully tighten it (or so I thought), but then I noticed that when trying to tighten it, it keeps spinning back to its original non-tightened position. It feels like the wires are forcing it to its loosened position.

Any tips for an easy fix?

RE: Upgraded from MK3 to MK3s + Ruby Nozzle now getting leaking

Sounds like 1) the heatbreak isn't screwed in far enough to the heatblock itself so it's not reaching the nozzle and 2) you have fully screwed in the nozzle such that it's binding against the heatblock, this explains it not getting tighter and the assembly falling back to an untightened state. The nozzle should be maybe 0.5mm away from fully screwed in when correctly installed.

The nozzle and the heatbreak MUST contact each other inside the heatblock for proper sealing and installation, or else filament will leak out, among other things. Take a look at Prusa's or E3D's instructions for changing a nozzle for what needs to be done.