Unable to unclog filament

I was doing a print and at one point nothing was coming out of the extruder. I looked at the gears that pull the filament and push it into the top of the extruder and although the gears were moving the filament was not.

I stopped the print.

I ran the Load Filament process and while the gears were moving I tried pushing the filament down into the extruder, with no success.

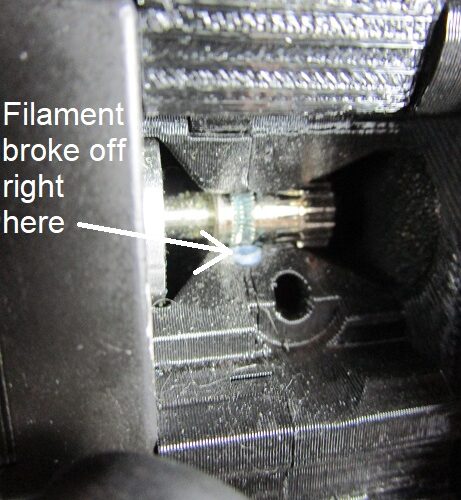

I ran the UN-Load Filament process and pulled on the filament to remove it but it wouldn't come out. I pulled and pulled and pulled and finally the filament BROKE right at the top of where it enters the extruder. See the photo:

I tried Load Filament again, with a new piece of filament to push down into it, to no avail. It just wouldn't accept the new filament. Clearly the old filament that's still in it is clogged somehow and simply will not move and won't heat up enough to melt so that it can be pushed through. I even tried selecting a higher temperature for the hot end, hoping that enough heat would get up to that part of the extruder and melt the clog. But that didn't work either.

I heated the extruder and used the thin needle inserted into the nozzle and it went all the way in, with some melted filament coming out. But subsequent running of the Load Filament process again did nothing. There is still a clog in it, apparently very near the top.

So, now what do I do?

Best Answer by kenatno10:

Me too ,

If you go to the prusa main website , there is a section on replacing the tube in the knowledge section (assembly manuals)

It was a fiddly job , clean the hot end carefully .

New tubes come with the kit.

Becareful of the thin wires for the fans and hotend.

Like yourself i was daunted by the job , just take your time and read instructions and follow one step at a time.

I replaced the nozzle due to build up behind the face of the nozzle.

Becareful lifting the tube retaining collar , may be easier with a extra pair of hands to help hold the hold end assembly

RE: Unable to unclog filament

Hi , had the same problem.

I had to replace the white ptfe tube in the extruder head and also changed the nozzle.

A pain after only just building the printer.

I think it is caused by melted filament building up around the nozzle side of the tube , then getting pulled back into the plastic tube and sticking inside.

RE: Unable to unclog filament

@kenatno10

But HOW to do that? I built mine from the kit so you MIGHT think I know how to disassemble the extruder and put it all back together again. But, NOPE.

Surely this must be something that numerous people continue to encounter. Heck, I had encountered something similar a few weeks back but was finally able to clear the clog with multiple Load and UnLoad Filament operations. But not this time. So where's the comprehensive video on how to disassemble it down to the point where you can clean out or replace that tube and then put it all back together again? Because it appears that THAT is what I need.

RE: Unable to unclog filament

Me too ,

If you go to the prusa main website , there is a section on replacing the tube in the knowledge section (assembly manuals)

It was a fiddly job , clean the hot end carefully .

New tubes come with the kit.

Becareful of the thin wires for the fans and hotend.

Like yourself i was daunted by the job , just take your time and read instructions and follow one step at a time.

I replaced the nozzle due to build up behind the face of the nozzle.

Becareful lifting the tube retaining collar , may be easier with a extra pair of hands to help hold the hold end assembly

RE: Unable to unclog filament

I have on occasion used tungsten wires to push the filament into the heated hot end. I remove the nozzle and use a 1mm and 1.6 mm tungsten rods. I heat the hotend up to about 10C above the heating temp of the filament and wait about 2 minutes then I gently push with a rod with the extruder disengaged.

--------------------

Chuck H

3D Printer Review Blog

RE: Unable to unclog filament

@kenatno10

Thank you for the suggestion. I found the instructions you mention. One thing I notice right away is that it says:

RE: Unable to unclog filament

Once i replaced the tube and nozzle i had no further problem as the filament was around the end of the tube which goes down inside .

My problem happened when the filament snapped during the unloading , this seemed to be because the filament had melted around the bottom of the tube. In other words , could not retract.

I also carefully scrapped off the extruder filament feed gear teeth.

On reloading a new filament , i made sure i pushed in through .

You could try moving the extruder to the top and remove the nozzle and use a torch / mirror to look upwards .

RE: Unable to unclog filament

I followed the instructions as suggested by kenatno and fortunately it wasn't as difficult as I had anticipated. When I got the tube out I found that it was completely filled with filament. I was able to push it from one end and then pull it all out from the other end. You can see that both ends of the filament "slug" is thicker, so one or both ends appears to be what had been the blockage.

The kit came with an extra tube so I put the new one into the hot end, reassembled everything, and it's printing right now. Looks good so far.

I'm glad that the kit came with a replacement tube. PRUSA must be aware that it's a problem sometimes. But so far I've had two of these kinds of clogs. I'm thinking of ordering a few spare tubes just so when this happens again I don't have to wait to load a new one.