Tired and indignant

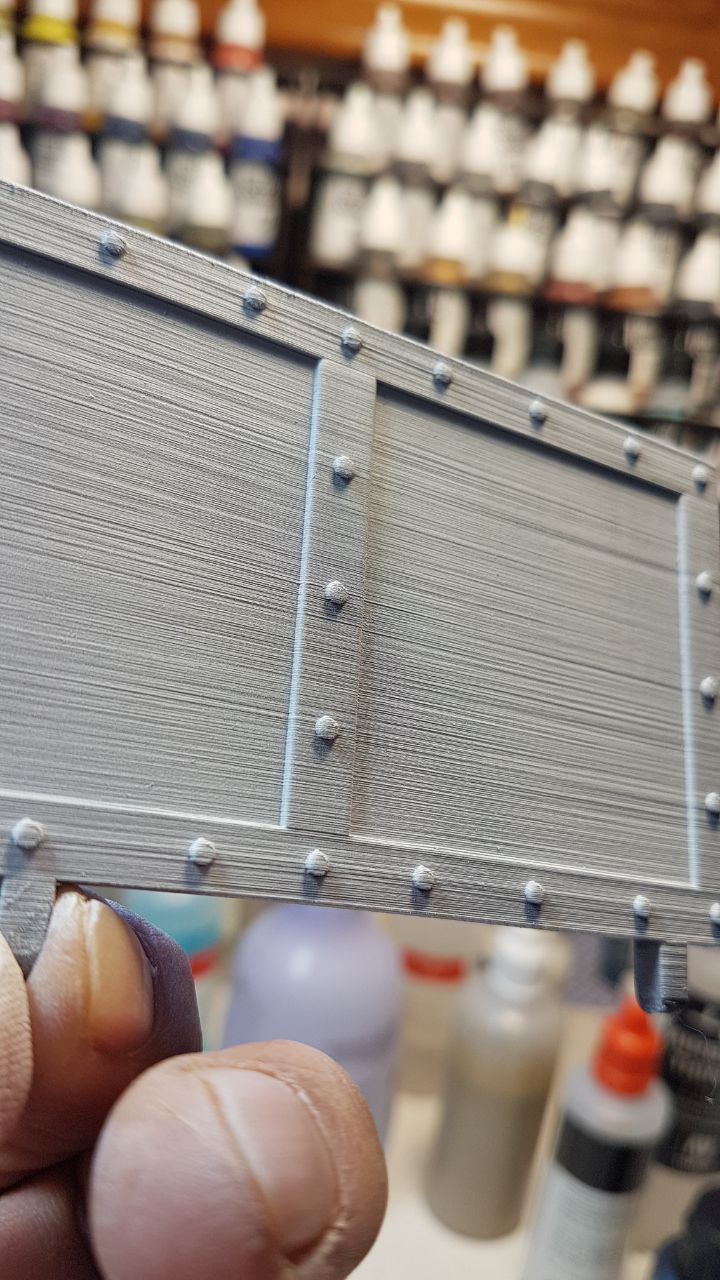

I was a happy possessor of a prusa mk2s and decided to change to the new mk3 in kit. Since then I have not gotten a good impression due to the irregularity of extrusion. From support, I have been told to adjust belts, calibrate the extrusion and check screws. It is all right and well assembled, but the problems remain the same. I attached a photo so you can see what I'm talking about. It is taken with the necessary light to highlight the surface irregularities of the extrusion inconsistency. Now I can not return it and I have lowered the quality of my impressions. What I can do?

A greeting.

Carlos Díaz

Re: Tired and indignant

i haven't been happy with my mk3 either. my mk2s is outputting superior prints.

i have seen ringing, moire pattern, this wiggling of layers that makes no sense, live Z problems. add in Filament sensor errors, Fan errors, crash detection layer shift and failures.

i have literally rebuilt my machine changing out the X parts for updates.

it all seems to be firmware related. there are still major bugs with it.

i have checked my belts everything appears to be correct nothing is loose. i did discover on one print that was REALLY bad that my Y belt assembly had gotten loose but i quickly fixed that and re-calibrated everything again.

from day one my very first print i was taken back by the print quality i was getting not matching the MK2S at all. i figured it was just the way the new hotend worked but after these last few weeks its obvious the MK3 has major problems.

i would like to see the staff on these forums really telling us what is going on so far it is other users helping each other out with no real communication from prusa itself :(.

“One does not simply use a picture as signature on Prusa forumsâ€

Re: Tired and indignant

I'm wondering about this issue as well. Is it extrusion inconsistency, or some type of X/Y movement? I had assumed it was my Z axis rods having slack or something, because I was seeing it on both X and Y.

Flex3Drive coming soon, so I back burnered the issue until I have that installed.

My MK3 Parts: [Bowden] [New Shoes] [TPU Micro Springs]

Re: Tired and indignant

Now I can not return it and I have lowered the quality of my impressions. What I can do?

I'm assuming that print has already been through the standard troubleshooting recommendations:

-100 mms or lower print speed

-50% perimeter speed or similar

-1000 mms2 acceleration or similar

-10 jerk or lower (I use 8)

The lines do suggest backlash somewhere, and the ringing suggests its very fast. lot easier to troubleshoot that with a cube or something like a temp tower.

Re: Tired and indignant

there is still a problem with the mk3 extrusion at different resolutions.

about 2 firmware fixes ago they supposedly fixed issues with higher resolutions. anything under .2mm height was massively under extruding. i had my multiplier set for like 1.5 the firmware fix admitted they miss counted extruder counts for filament well it kinda fixed it but there is another problem because just like live Z inconsistancy there is still as issue with extrusion consistency. The machine like wigs out and you get this wavy layer line per layer. it gets fat/thin back and forth. it makes it seem like there is a problem with the filament or the belts but you put the same Gcode and filament in a MK2s and it works fine, doesn't work right on the mk3. you check the belts and everything appears tensioned correctly.

since you can't get 100% consistency it is impossible to fine tune the machine and you are left with crappy print quality.

you spent hours running benchmark tests think you got it dialed in and then go for a print and it comes out like trash.

“One does not simply use a picture as signature on Prusa forumsâ€

Re: Tired and indignant

This could also be caused by changing filament diameter, couldn't it?

My MK3 Parts: [Bowden] [New Shoes] [TPU Micro Springs]

Re: Tired and indignant

well if you are using good filament and you take that same filament and put it in a mk2s and it works fine then logically there has to be something going wrong in the new mk3. i think the problem is all related. there is a live Z bug right now where when the machine is cold and you fire it up for the first time and run a LIVE Z calibration everything goes kind of normal it does seem to under extrude. now when the machine is all warmed up and ready to go and you run the same test suddenly the straight 45 degree lines get all wavy narrow and thick and also the Live Z like gets ignored and the nozzle is too close to the bed.

I think the same bug occurs as the layers go up on a print. like the bottom is ok then you get this ringing pattern as it goes up i think the layers are also getting skewed somehow even with crash det turn off. when you make a calibration cube it doesn't look right it measures out ok 20mmx20mmx20mm but it looks skewed to my eye and the ringing pattern is present. the skew might be optical because of the pattern that occurs thick/thin.

because LA is turned off in the firmware because of the the octo bugs the edges are all rounded unlike the MK2s.

so it is a combination of problems but i think they are related in the firmware. like some kind of Step miscount in the axis. there was already the step miscount for the filament which i think is still present in some form.

“One does not simply use a picture as signature on Prusa forumsâ€

Re: Tired and indignant

Now I can not return it and I have lowered the quality of my impressions. What I can do?

I'm assuming that print has already been through the standard troubleshooting recommendations:

-100 mms or lower print speed

-50% perimeter speed or similar

-1000 mms2 acceleration or similar

-10 jerk or lower (I use 8)

The lines do suggest backlash somewhere, and the ringing suggests its very fast. lot easier to troubleshoot that with a cube or something like a temp tower.

Of course I have already tried to work with ridiculous speeds and accelerations and the result is even worse

Re: Tired and indignant

This could also be caused by changing filament diameter, couldn't it?

I have tried with three different manufacturers and in all the result is very similar. In other colors it is not appreciated so much, but that does not mean that it is good. I paint the printed pieces

Re: Tired and indignant

Hello Carlos,

What have you tried already? It looks like a tiny object. What's the size of it and what settings/slicer have you used? What kind of filament, PLA/PETG/ABS?

Can you print the same gcode on MK2 and MK3 and compare the results?

The printed object doesn't look awful at all, so it's hard to tell how you can improve it without knowing the details.

Often linked posts:

Going small with MMU2

Real Multi Material

My prints on Instagram

Re: Tired and indignant

so i'm also very disappointed from the mk3 and the support in general, I showed them videos of my right spindle which has a massive amount of wobble. Support told me thats nowhere near where it would affect my print quality...

All they do is let you print different models for hours and hours ... but no solutions ...

https://drive.google.com/open?id=1-QT5jeNpxZLAOObDkOo6JQxT4nw2A_ps

Re: Tired and indignant

Hi

I'm in the same position: I sold my MK2S and ordered a MK3. Now I'm here and I am disappointed of the print quality.

My prints look like yours and I have no idea how to fix it.

I tried the follow things:

- Newest firmware -> didn't helped

- Tighten the belts -> didn't helped

- Loosen the belts -> didn't helped

- Check all screws -> they are all tight

- Check rigidity of frame -> the frame is much more solid than the MK2

- Check Flow rate -> If i let the extruder extrude 100 mm filament, it extrudes exactly 100 mm

- Print at 90%, 95%, 100% and 105% flow rate -> didn't helped

- Tried different colors and brands of filament -> didn't helped

- Tried different print speeds -> didn't helped

- Printed and changed the X-Belt Idler to the new R2 version -> didn't helped

- Tighten the screws on the extruder idler -> didn't helped

- Loosen the screws on the extruder idler -> didn't helped

- Tried different slicer -> didn't helped

Re: Tired and indignant

its got to be better than my wanhao i3 plus and it prints great. so its got to be better .......right ?

Re: Tired and indignant

Hello Carlos,

What have you tried already? It looks like a tiny object. What's the size of it and what settings/slicer have you used? What kind of filament, PLA/PETG/ABS?

Can you print the same gcode on MK2 and MK3 and compare the results?

The printed object doesn't look awful at all, so it's hard to tell how you can improve it without knowing the details.

This printed PLA, with a layer height of 0.1. The piece makes a total of 10 cm by 5 cm. I do not have the mk2s right now, but I've been working with it for many hours and I know what it can do, and it works better than the mk3. If you really do not appreciate the poor print quality, any 3D printer would work for you

Edit. Slicer used is Simplify

Re: Tired and indignant

its got to be better than my wanhao i3 plus and it prints great. so its got to be better .......right ?

I have never tried that machine and I do not know what to say, but at this moment, my mk3 is not going well at all, and it seems to be something generalized

Re: Tired and indignant

I'm in the same position: I sold my MK2S and ordered a MK3. Now I'm here and I am disappointed of the print quality.

My prints look like yours and I have no idea how to fix it.

I tried the follow things:

...

Hello Stefan,

Welcome to this forum.

It's hard to believe that all the things you have tried didn't change the print quality. For example I can see on my MK2 the difference in print quality if I change the speed/acceleration settings (same object, same slicer, same material).

It's always hard to understand what's happening during the print. The only thing I could suggest is to start very simple. Take a PLA filament which you know it's consistent and proven. Take a simple object like a wall with 4 perimeters. Multiply it, place it with different orientation and print in one batch. Change the speed settings towards fast, print again and verify the results. Change the speed towards low, print again and compare.

Deactivate retraction, play with different temperatures. This way you can see how each axis is performing and analyzing it one by one.

Often linked posts:

Going small with MMU2

Real Multi Material

My prints on Instagram

Re: Tired and indignant

These are some of my tests among the many that I have done

Re: Tired and indignant

This printed PLA, with a layer height of 0.1. The piece makes a total of 10 cm by 5 cm. I do not have the mk2s right now, but I've been working with it for many hours and I know what it can do, and it works better than the mk3. If you really do not appreciate the poor print quality, any 3D printer would work for you

Edit. Slicer used is Simplify

Couple more things you can also try:

1. You mentioned lowering the speed looks worse. Try to increasing the speed and check the results. Maybe there is an issue with the temperature.

2. Try to print two objects at the same time with 90 degrees rotated.

3. Try 0.15 and 0.2 layer heights. Sometimes the fine resolution is causing unforeseen issues.

4. I assume you're on the most recent firmware, driver package, Slicer version. Check that!

5. Deactivate all the fancy features in MK3, print from SD card

It would also help to see the picture of the sliced wall. It's important how the slicer would like to fill the wall.

Often linked posts:

Going small with MMU2

Real Multi Material

My prints on Instagram

Re: Tired and indignant

http://manual.slic3r.org/troubleshooting/dimension-errors

Per the link above, scroll down a bit until you start getting to the layer side shots. Can you print some one perimeter cubes with no top/infill, and check to see if the layers are wobbling back and forth per the top image, or if they are getting fatter/narrower per the bottom image? This will let us know if this is a wobble issue vs a flow issue.

Really hoping this is an irregular flow issue. If it is, my upcoming 40:1 modification should fix it nicely lol.

My MK3 Parts: [Bowden] [New Shoes] [TPU Micro Springs]

Re: Tired and indignant

This printed PLA, with a layer height of 0.1. The piece makes a total of 10 cm by 5 cm. I do not have the mk2s right now, but I've been working with it for many hours and I know what it can do, and it works better than the mk3. If you really do not appreciate the poor print quality, any 3D printer would work for you

Edit. Slicer used is Simplify

Couple more things you can also try:

1. You mentioned lowering the speed looks worse. Try to increasing the speed and check the results. Maybe there is an issue with the temperature.

2. Try to print two objects at the same time with 90 degrees rotated.

3. Try 0.15 and 0.2 layer heights. Sometimes the fine resolution is causing unforeseen issues.

4. I assume you're on the most recent firmware, driver package, Slicer version. Check that!

5. Deactivate all the fancy features in MK3, print from SD card

It would also help to see the picture of the sliced wall. It's important how the slicer would like to fill the wall.

I have done all the checks as you can see in the previous photos with many tests and others that went to the trash. The only thing I have not tried is to disable all those functions. Now I am printing a cube again.

Thanks for the support, help and time