Re: [Testers Needed] Inconsistent Extrusion

I did the same test on my MK3 and got a better but not good result.

The problem with the wall is that even if the wall is made 0.45 mm thick, it is printed twice at the same layer level (back and forth).

Thanks for testing on MK3. But I can't confirm your suggestion. Here is a gcode snippet. You can clearly see it's extruding one line in one direction, and extruding back at 0.15 higher

...

G1 F1210

G1 X75.225 Y104.975 E0.00130

G1 X174.775 Y104.975 E2.59385

G1 X174.775 Y105.025 E0.00130

G1 X75.285 Y105.025 E2.59229

...

I think the filament is still too hot and previous layer is moving/melting randomly. I tried 0.2 and 0.15 with the same results. Your print looks way better then mine and with defaults.

Just for clarification, I'm not diminishing a work is done for extrusion investigation on MK3. Just offering my old MK2S with more then 100km filament went through for testing and comparison.

Often linked posts:

Going small with MMU2

Real Multi Material

My prints on Instagram

Re: [Testers Needed] Inconsistent Extrusion

That particular STL needs to be sliced correctly. If you don't allow single extrusion walls, it does the double pass. This also has the side effect of making the wall too thick (this is a .5mm wall, in my case it printed it .975mm thick.

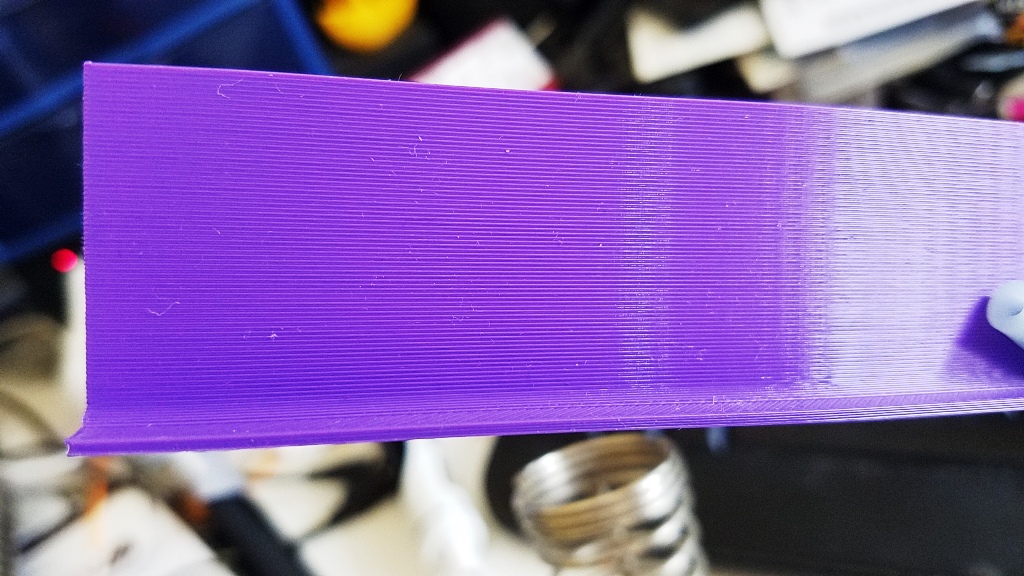

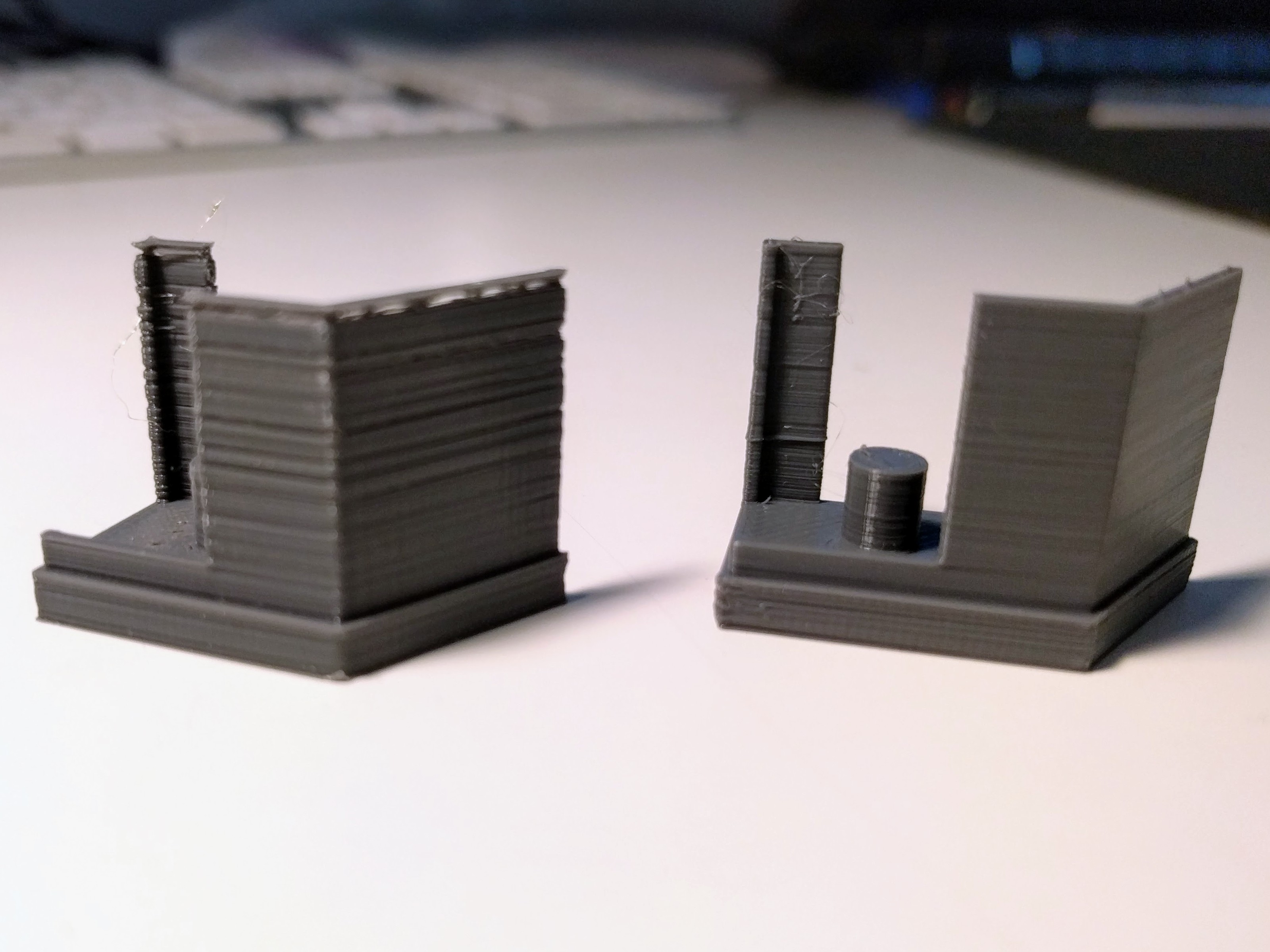

Here is the improper slice:

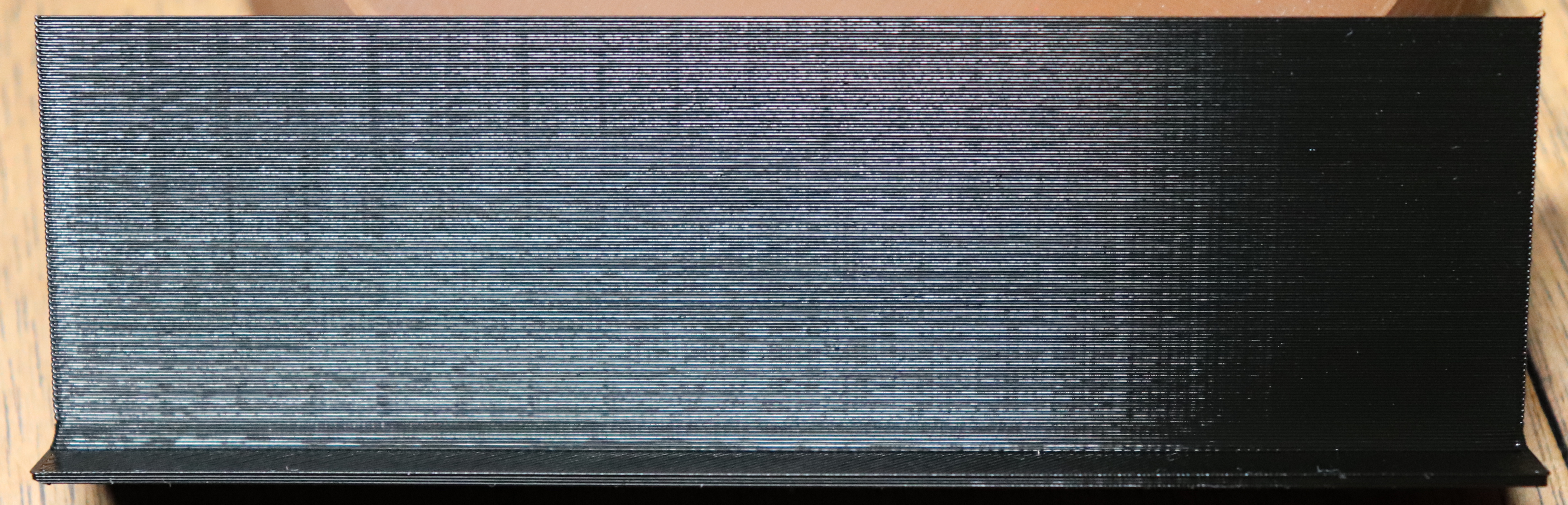

And here it is after enabling single extrusion walls. This is the proper width (measured about .57mm thick):

Re: [Testers Needed] Inconsistent Extrusion

Here's a better shot of the proper sliced model:

Really nice and even lines! I found this option in S3D but where do you have this option in Slic3r?

Would be great if you can post your slicer settings for that. I would like to reproduce it on my printer.

Often linked posts:

Going small with MMU2

Real Multi Material

My prints on Instagram

Re: [Testers Needed] Inconsistent Extrusion

I know this is stale by now, but I just read the comments chris3030 made. Talk about moving the goal post!

him: Mine are perfect!

us: no, look at that

him: oh that? I like that! it's a feature not a bug! (because I can't admit that I'm wrong)

I know I shouldn't make a post like this that doesn't further the conversation and only serves to call someone out, however people also shouldn't be butting their heads in to a discussion only to try to derail it because of their own ignorance.

(And yes, my $200 creality ender-2 currently prints better than my MK3. That's not the only printer I have that prints better than my MK3, I just don't think listing off a shit ton of printers does anything but prove that you're trying to out-do someone else.)

Anyone know what the current wait time on a MK2S kit is? lol

Re: [Testers Needed] Inconsistent Extrusion

Really nice and even lines! I found this option in S3D but where do you have this option in Slic3r?

Would be great if you can post your slicer settings for that. I would like to reproduce it on my printer.

Here's my S3D profile for this (Inland PLA).

Re: [Testers Needed] Inconsistent Extrusion

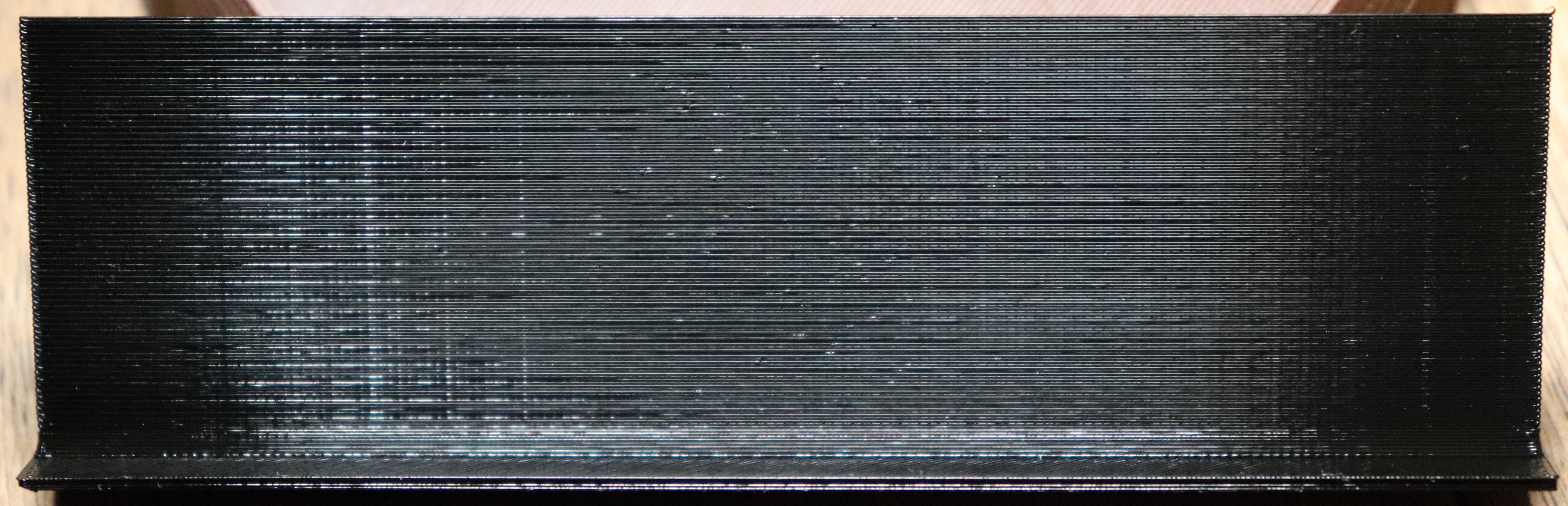

Thanks for the hint and the profile. Adjusted my profile and here we go, next version.

Often linked posts:

Going small with MMU2

Real Multi Material

My prints on Instagram

Re: [Testers Needed] Inconsistent Extrusion

At the momment I'm struggling with a problem with filament getting stuck at the bownden gears and I seem to have solved that (pending some more tests).

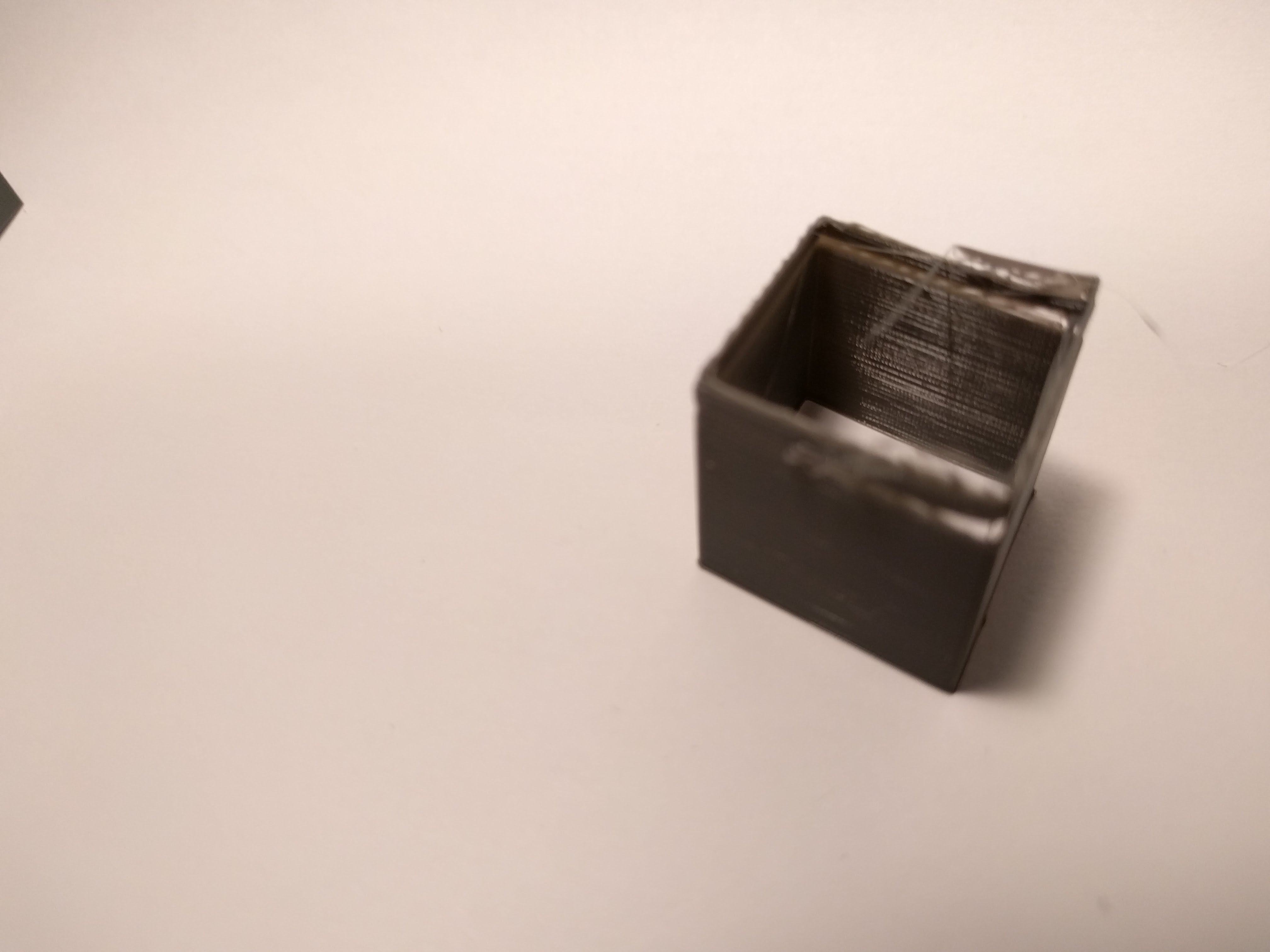

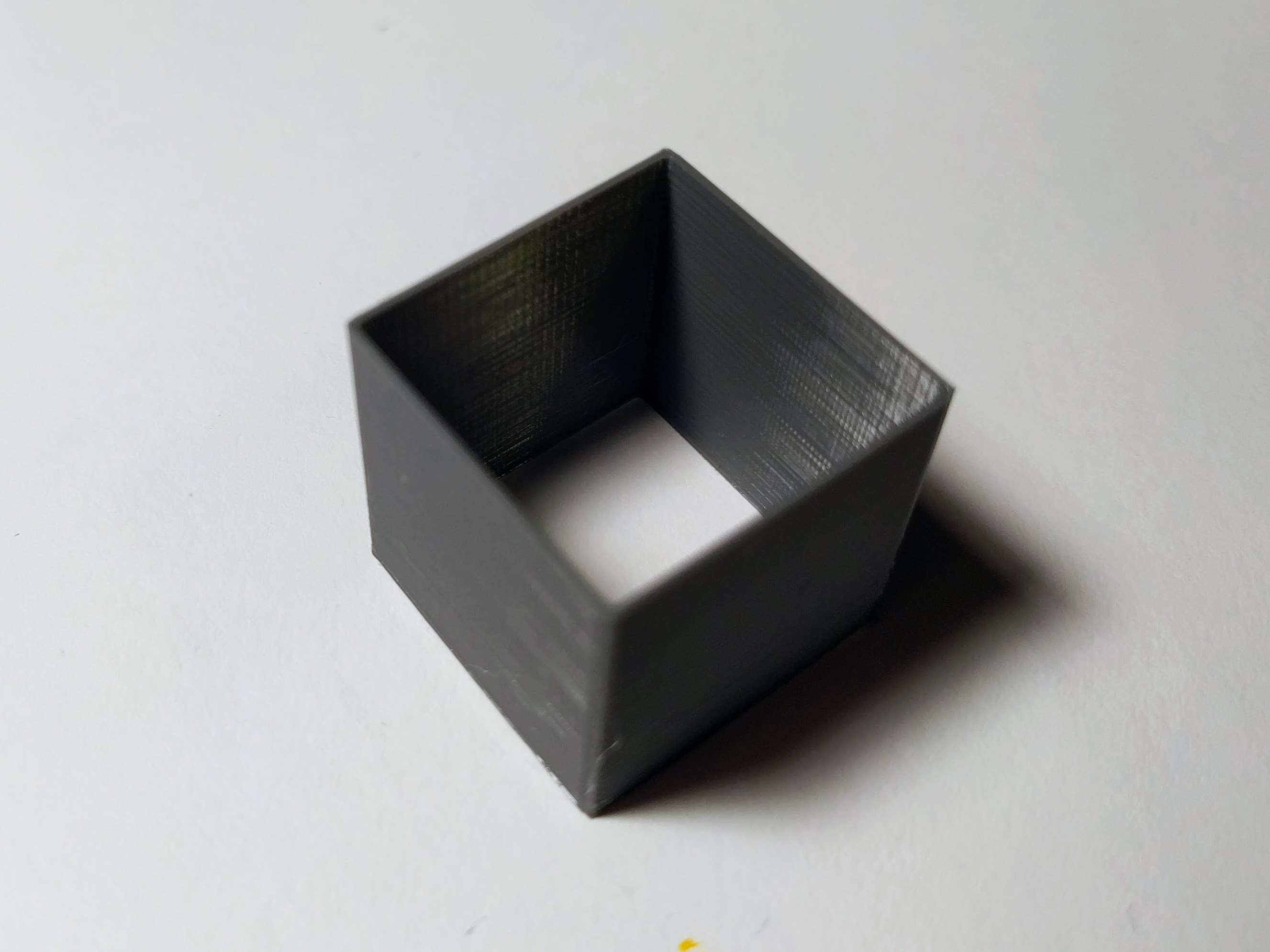

having that solved I get a more decent cube.

Before (don't mind the failed top, notice that the layer lines are way worse)

After

I'm not entirely happy with the current result but it's quite better

The difference is even more evident with this piece:

I solved (i guess) the issue by printing a piece that guides the filament before entering the heat sink. You can find the problem, lots of examples and the gueses at why in this thread:

https://shop.prusa3d.com/forum/others-archive--f66/clicking-printhead-filament-stuck--

the files that seem to have solved it for me in this one:

https://shop.prusa3d.com/forum/hardware-firmware-and-software-help-f64/filament-continually-clogging-and-getting-stuck-in-t15620.html#p78626

Re: [Testers Needed] Inconsistent Extrusion

Really nice and even lines! I found this option in S3D but where do you have this option in Slic3r?

I gather you found it ok? If not it's in Print Settings / Detect Thin Walls check box.

It makes all the difference.

Re: [Testers Needed] Inconsistent Extrusion

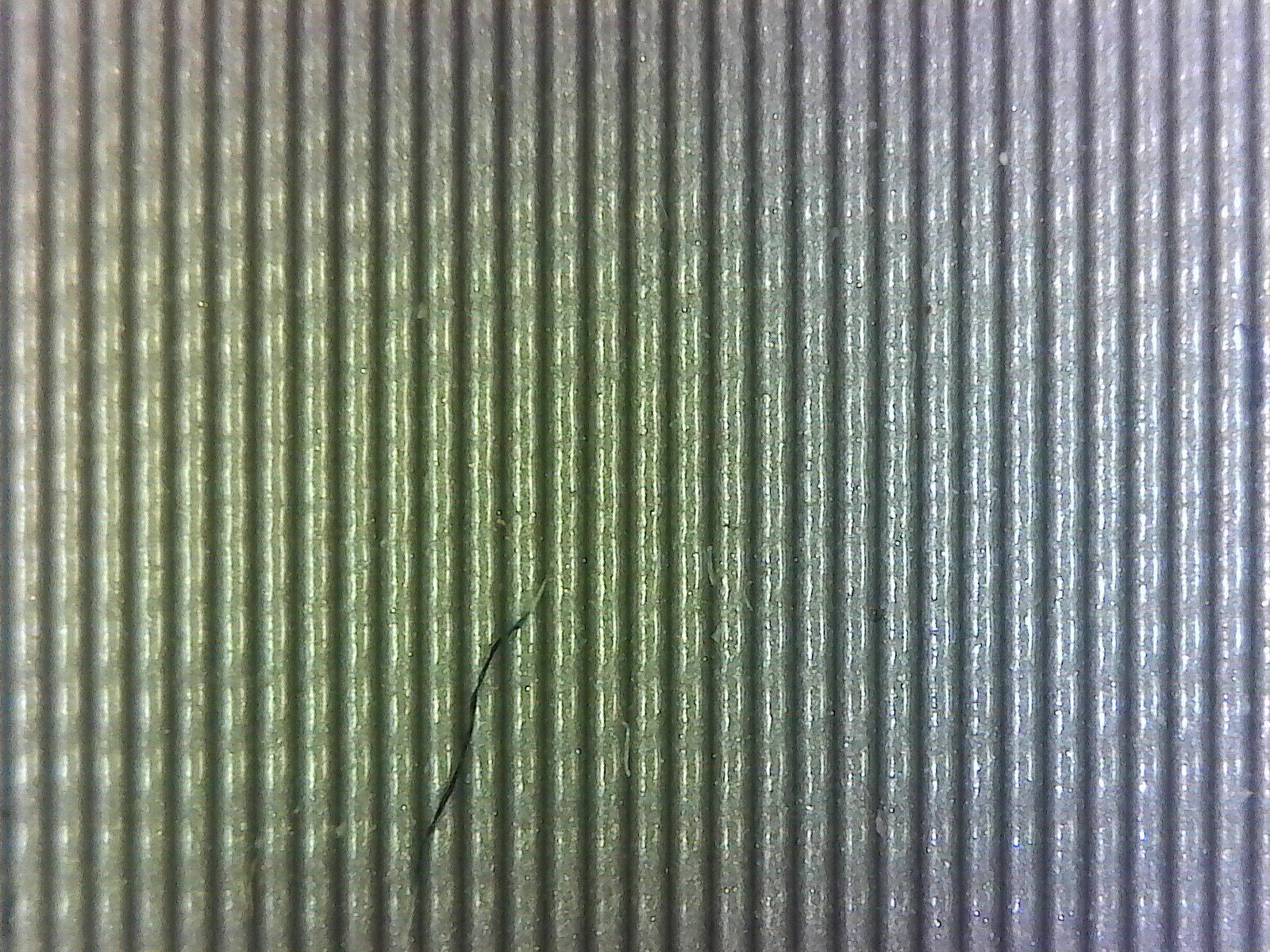

I took some microscope pictures of a test cube I printed. I'm not sure what conclusions to draw, but I post the pictures anyway.

You can certainly see the pattern, and it looks like the plastic is extruded in pulses. The last picture shows the top of the cube side.

Linus

Re: [Testers Needed] Inconsistent Extrusion

I would expect pulses at the microscopic layer- a stepper motor can only be pulsed, using steps and microsteps. It is very difficult to not have pulse shaped movement, especially under pressure.

Re: [Testers Needed] Inconsistent Extrusion

I took some microscope pictures of a test cube I printed. I'm not sure what conclusions to draw, but I post the pictures anyway.

You can certainly see the pattern, and it looks like the plastic is extruded in pulses. The last picture shows the top of the cube side.

What layer height is this specifically? Also, is this the most " visible" you can get the reflections?

Your microscope, can prove my theory right, or wrong.

Since I'm currently down a Mk3... (heh... I'm so sad right now)

I would love to do math in attempt to solve this.

Hi, I'm Sean. I used to work on CNC machines.

I try to not make mistakes, but the decision is YOURS.

Please feel free to donate to my filament/maintance fund.

Re: [Testers Needed] Inconsistent Extrusion

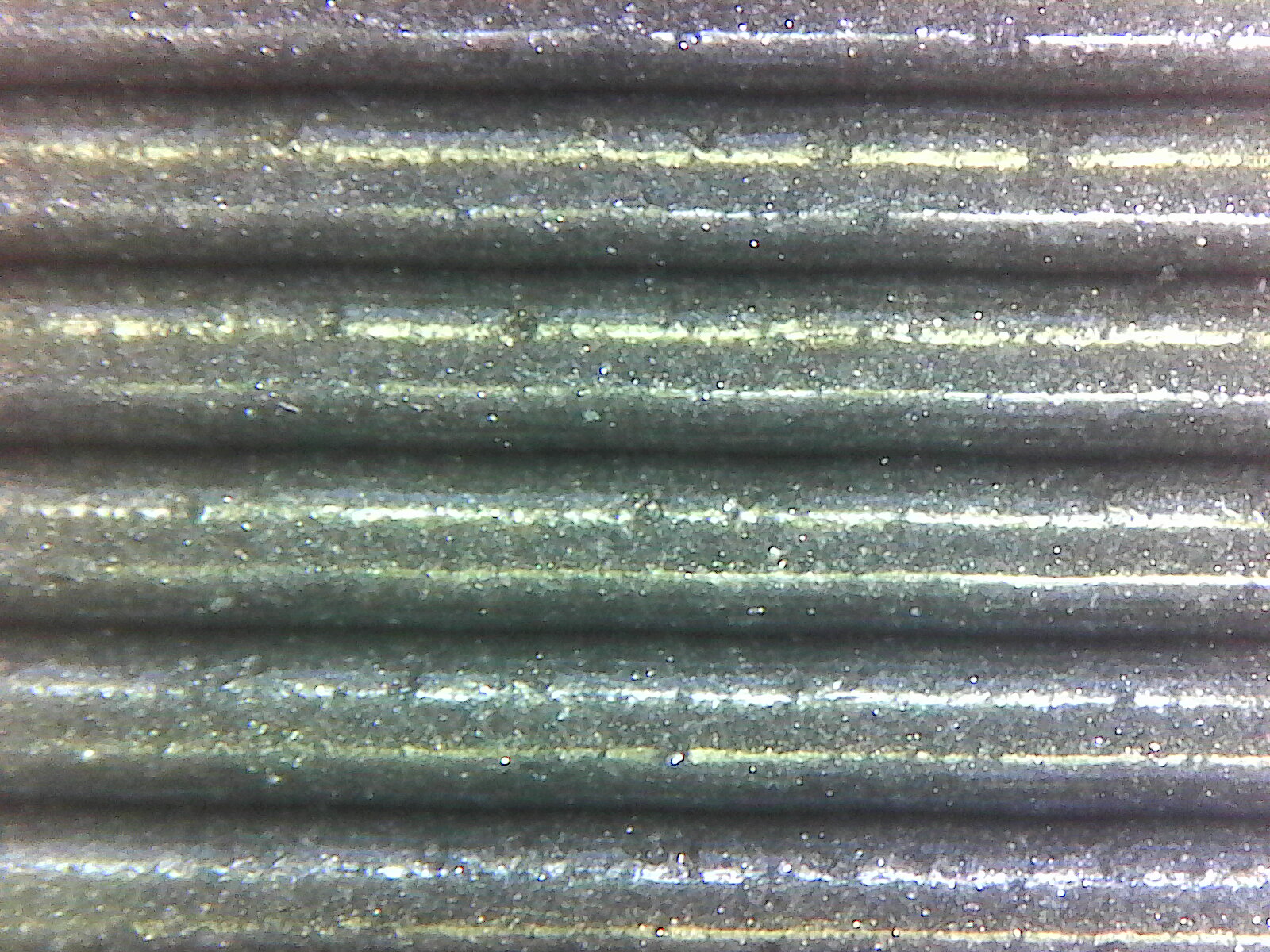

I think I have definitive proof of this issue. Attached is a single wall test object printed at 30mm/s

About every 5mm I increased the amperage to the motor from about 300mA up to full power at around 950mA. (By the settings I used, 20, 30, 40, 50, 63) EDIT: The object is about 30mm tall.

Anyway, I want you to notice that with the "lower" amperage lines (towards the bottom) they are "smoother" but they are still rather visible. However once I get the power cranked up to wide open, the lines look BINARY. In fact, it is SUPER easy to see, the exact "over" "under" extrusion. And it's not a "fade" like I was thinking that it would be. It's very much a "hard switch" between the two.

Ok, now what we are looking at is the top left corner of the test object. (same photo)

I want you to notice how it looks "woven". You see that every other layer, is either "over" or "under" extrusion. (visible as a reflection, or a shadow)

using my layer lines as a measuring tool, I measured 1mm of vertical height, and then took that measurement to find that the "pattern" repeats every ~4mm.

My "paper math" said 3.5mm, which I assumed was high, and I called 3.0 to 3.3.

My guess is that every ~4mm of linear travel will yeild 1 "step". (a full 1/200th of a rotation step)

Something is happening at some point in the step to "increase" and "decrease" the power, and it directly related to the location of the step, within the step.

So under a microscope, there would be 16 steps on both "under" and "over".

I don't even know how to properly explain the problem.

But basically, there's I'm gonna say "two" modes for microsteps.

"hard" steps, that it steps "harder" and "easy" steps, that it steps easy.

The "Hard" and "easy" are configured wrong.

***

EDIT: You should rename this issue to "consistent extrusion issues". 😈

Hi, I'm Sean. I used to work on CNC machines.

I try to not make mistakes, but the decision is YOURS.

Please feel free to donate to my filament/maintance fund.

Re: [Testers Needed] Inconsistent Extrusion

I took some microscope pictures of a test cube I printed. I'm not sure what conclusions to draw, but I post the pictures anyway.

You can certainly see the pattern, and it looks like the plastic is extruded in pulses. The last picture shows the top of the cube side.

What layer height is this specifically? Also, is this the most " visible" you can get the reflections?

Your microscope, can prove my theory right, or wrong.

Since I'm currently down a Mk3... (heh... I'm so sad right now)

I would love to do math in attempt to solve this.

This is printed with the FAST 0.2 mm slic3r profile, using Prusa gray PLA. I will try to get a picture with better lighting, to be able to see the structure. I will also do another print that I will interrupt, to better see a layer from above.

Re: [Testers Needed] Inconsistent Extrusion

16 Steps over and 16 Steps underextruded....

I would say, the Bondtech-Pulley is rotating out of center.

Are you with me?

Re: [Testers Needed] Inconsistent Extrusion

Oh, bullshit, forget that. If the pulley were spinning out of the middle, the different areas would be much longer.

Re: [Testers Needed] Inconsistent Extrusion

Sean, can you post these findings on the GitHub issue? We finally have Prusa paying attention to it.

My MK3 Parts: [Bowden] [New Shoes] [TPU Micro Springs]

Re: [Testers Needed] Inconsistent Extrusion

Hey guys. Ive been super happy with my printer but noticed this problem recently. Thought I'd contribute to the conversation. I'm glad its been recognized.

Re: [Testers Needed] Inconsistent Extrusion

If the pulley were spinning out of the middle, the different areas would be much longer.

Rather than ~4mm of linear travel per "cycle", if it was the bondtech, the "full" cycle would be 800mm of linear travel. and on my test print, that would be about every 6 layers.

I would also like to post a warning to anyone who want to try what I did with adjusting amperage on the motors.

In my 10 minute test print, at 5 minutes, the motors were "cool". At 10 minutes, they were VERY UNPLESANT.

I'm not gonna say the motor would actually overheat, but I bet it would get hot enough to cause damage to the extruder assembly. Be *VERY* careful about turning the amperage up guys.

Hi, I'm Sean. I used to work on CNC machines.

I try to not make mistakes, but the decision is YOURS.

Please feel free to donate to my filament/maintance fund.

Re: [Testers Needed] Inconsistent Extrusion

So doesn't this point to the extruder needing to be geared as others have mentioned?